A kind of heat-dissipating powder coating and preparation method thereof

A technology of powder coatings and heat-dissipating fillers, applied in powder coatings, polyester coatings, anti-corrosion coatings, etc., can solve problems such as poor heat dissipation effect of a single heat-dissipating material, failure to solve the problem of filler accumulation, and no specific solution proposed. Promote the effect of heat dissipation, promote the degree of directional arrangement, and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

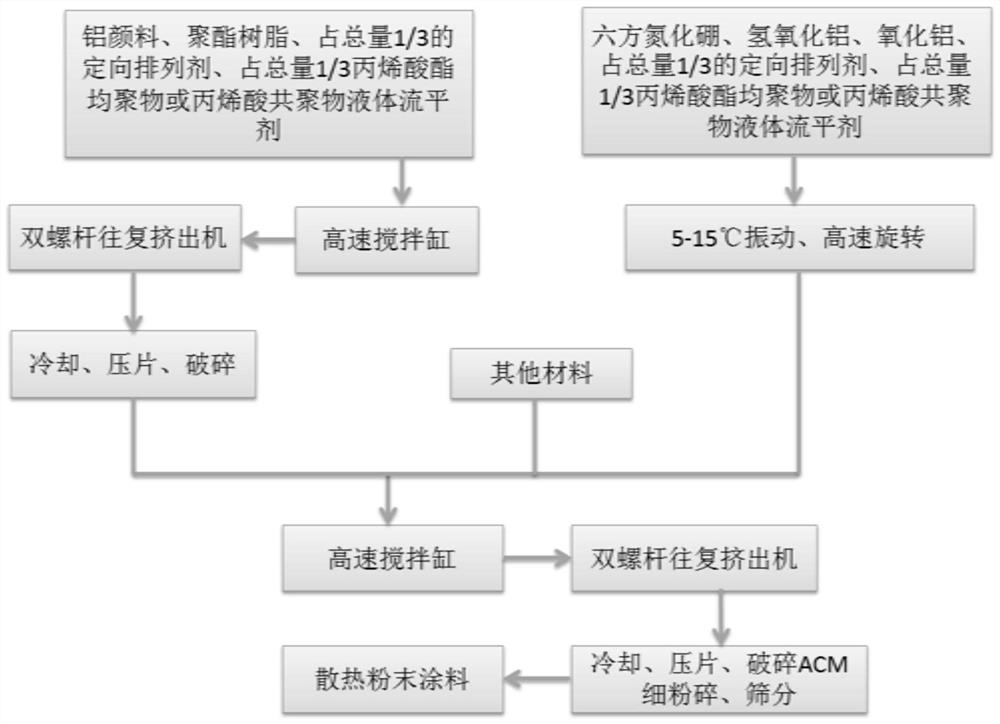

Method used

Image

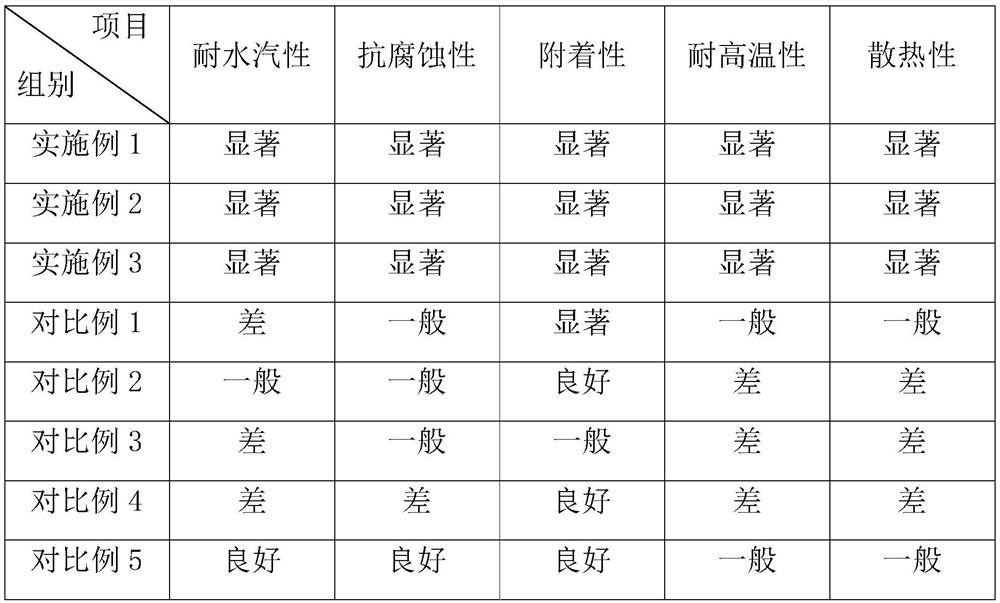

Examples

Embodiment 1

[0033] The invention provides a heat-dissipating powder coating and a preparation method thereof. The heat-dissipating powder coating comprises the following components in mass percentage: 59.3% of a saturated carboxyl-terminated polyester resin, 4.5% of a curing agent, 20.8% of a composite heat-dissipating filler, and 1% of an alignment agent , titanium dioxide 5%, leveling agent 0.5%, magnesium aluminum silicate 1%, brightener 0.5%, benzoin 0.2%, polytetrafluoroethylene 0.2%, antioxidant 0.1%, pigment 1.5%, aluminum pigment 5.4%; The composite heat-dissipating filler is prepared by successively ball milling, mixing and spheroidizing hexagonal boron nitride, aluminum hydroxide and aluminum oxide.

[0034] Wherein, in this embodiment, the saturated carboxyl-terminated polyester resin is a polyester resin with an acid value of 30-40 mgKOH / g, its addition amount is 59.3%, and the corresponding curing agent is TGIC, and the addition of the curing agent TGIC The amount is 4.5%; th...

Embodiment 2

[0044] The invention provides a heat-dissipating powder coating and a preparation method thereof. The heat-dissipating powder coating comprises the following components in mass percentage: 39.7% of saturated carboxyl-terminated polyester resin, 30% of curing agent, 13.2% of composite heat-dissipating filler, and 1% of orientation alignment agent , titanium dioxide 5%, leveling agent 1.0%, magnesium aluminum silicate 1%, brightener 0.3%, benzoin 0.5%, polytetrafluoroethylene 0.2%, antioxidant 0.3%, pigment 1.0%, aluminum pigment 6.8%; The composite heat-dissipating filler is prepared by successively ball milling, mixing and spheroidizing hexagonal boron nitride, aluminum hydroxide and aluminum oxide.

[0045] Wherein, in this embodiment, the saturated carboxyl-terminated polyester resin is a polyester resin with an acid value of 30-75 mgKOH / g, its addition amount is 39.7%, and the corresponding curing agent is an epoxy resin, and the epoxy resin The added amount is 30%; the lev...

Embodiment 3

[0055] The invention provides a heat-dissipating powder coating and a preparation method thereof. The heat-dissipating powder coating comprises the following components in mass percentage: 34.5% of a saturated carboxyl-terminated polyester resin, 18% of a curing agent, 15.5% of a composite heat-dissipating filler, and 2% of an alignment agent , titanium dioxide 5%, leveling agent 0.6%, magnesium aluminum silicate 1%, brightener 0.1%, benzoin 0.3%, polytetrafluoroethylene 0.4%, antioxidant 0.2%, pigment 1.0%, aluminum pigment 10.4%; The composite heat-dissipating filler is prepared by successively ball milling, mixing and spheroidizing hexagonal boron nitride, aluminum hydroxide and aluminum oxide.

[0056] Wherein, in this embodiment, the saturated carboxyl-terminated polyester resin is a polyester resin with an acid value of 30-75 mgKOH / g, its addition amount is 34.5%, and the corresponding curing agent is an epoxy resin, and the epoxy resin The added amount is 18%; the level...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com