mems capacitive air pressure sensor based on pn junction electrical isolation and anodic bonding technology

An air pressure sensor and anodic bonding technology, which is applied in microstructure technology, fluid pressure measurement using capacitance change, instruments, etc. To solve problems such as chemical promotion and application, to achieve the effect of excellent long-term vacuum maintenance ability, long-term stability and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation process of the present invention will be described in connection with the accompanying drawings and examples.

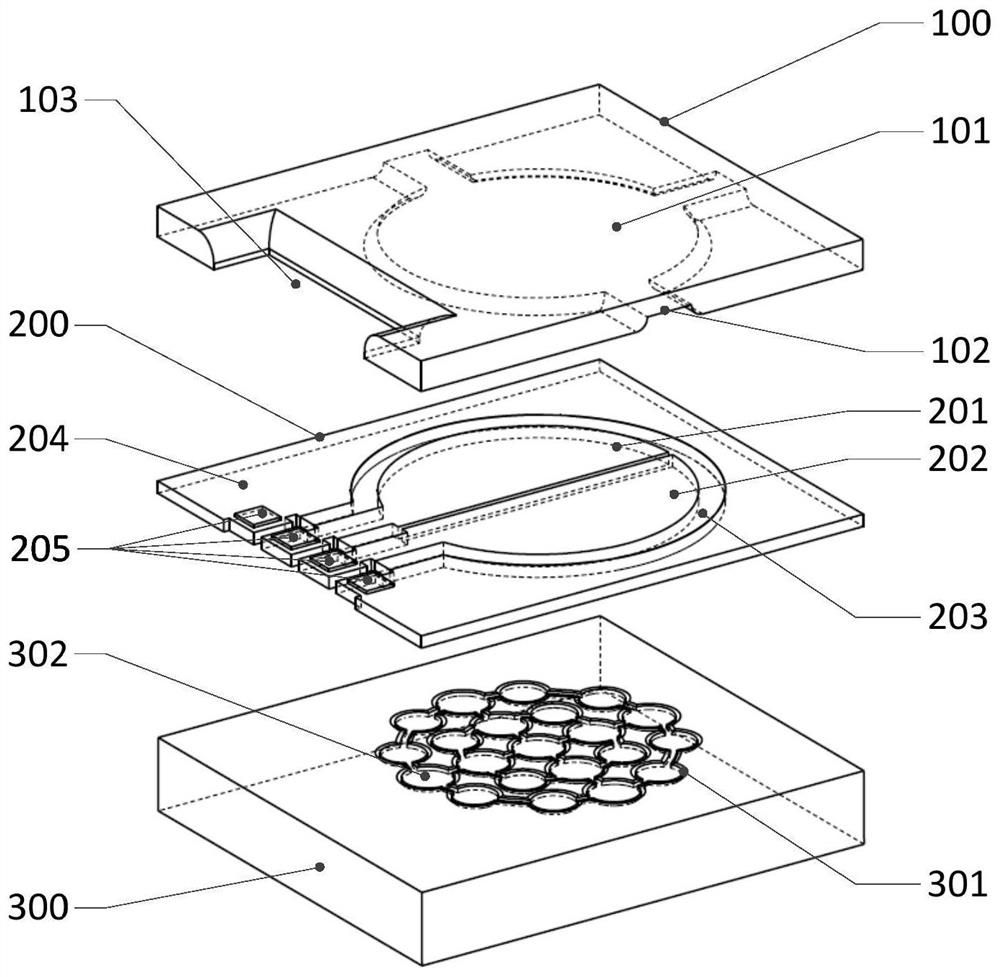

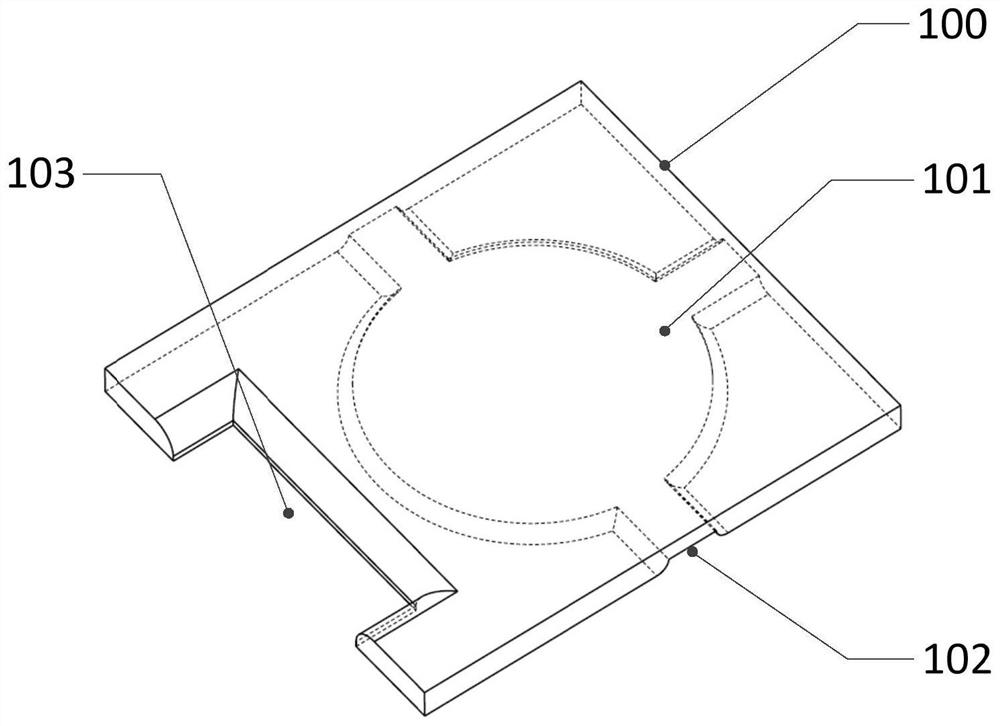

[0036]figure 1 For the three-dimensional separation anatomical diagram of the present invention, the capacitive air pressure sensor is bonded to the glass substrate 300 anode, and the air pressure sensitive film 200 is composed of the air pressure sensitive film 200, and the air pressure sensitive film 200 is composed of the glass cover 100 anode bonding.

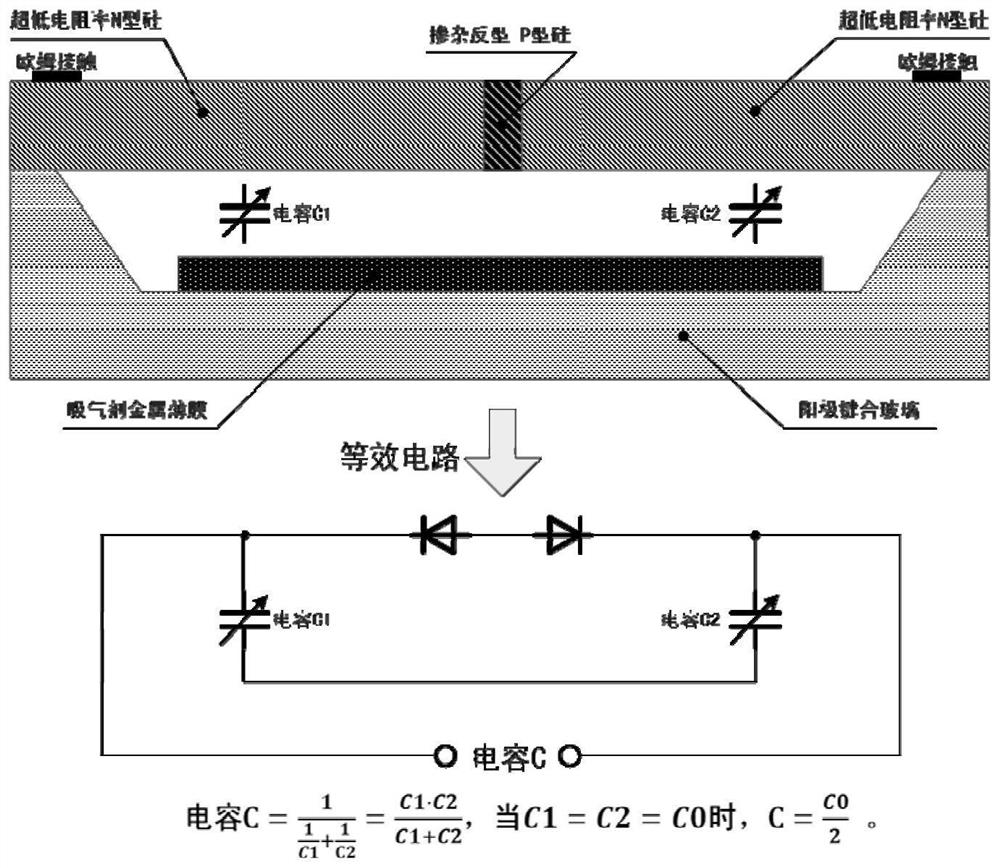

[0037] The gas pressure sensitive film 200 substrate material of the capacitive air pressure sensor is a device layer of an N-type ultra-low resistivity (<0.005 Ω · cm) SOI wafer, and the P-type silicon electrical isolation zone 203 is formed by recombining, the P The silicon electrical isolation zone 203 is a circular structure of one end opening, the inner diameter direction of the circular ring structure with a rectangular isolation gate; the p-type silicon electrical isolation re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com