Method for preparing 3-diethylamino-N, N-diethylpropionamide through amidation and catalyst and application thereof

A technology based on diethylpropionamide and diethylamine, applied in the direction of carboxylic acid amide preparation, physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, etc., can solve the problem of large catalyst consumption and reaction temperature Advanced problems, to achieve the effect of stable product performance, lower reaction temperature and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

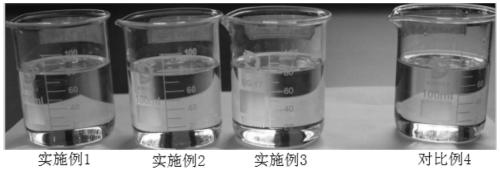

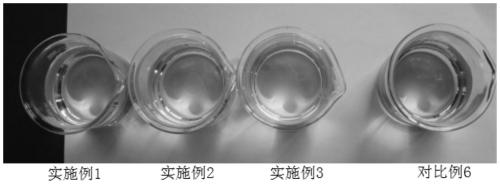

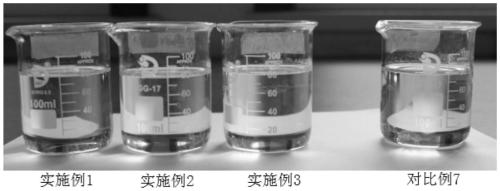

Embodiment 1

[0052] A method for preparing 3-diethylamino-N,N-diethylpropionamide by amidation, comprising the steps of:

[0053] (1) Measure 4.5g of multi-walled carbon nanotubes (length is 10-20nm, specific surface area is 523m 2 / g, internal diameter is 5-8nm, and external diameter is 12-16nm), pours in the three-necked flask that has condensing tube, adds the concentrated sulfuric acid that 9.0g mass concentration is 12.6% and the concentrated nitric acid that 2.25g mass concentration is 22.3% The mixed solution was heated to 40°C for ultrasonic dispersion for 1h with a power of 200W. After completion, it was washed 7 times with distilled water, and then vacuum-dried at -0.098Mpa and 80°C for 12h to obtain oxidized multi-walled carbon nanotubes.

[0054] (2) The oxidized multi-walled carbon nanotubes are transferred to a three-necked flask connected with a condenser tube, a vacuum pump, and a separatory funnel placed in an oil bath heating. In the separatory funnel, the mass concentrat...

Embodiment 2

[0058] A method for preparing 3-diethylamino-N,N-diethylpropionamide by amidation, comprising the steps of:

[0059] (1) Measure 4.5g of multi-walled carbon nanotubes (length is 10-20nm, specific surface area is 523m 2 / g, internal diameter is 5-8nm, and external diameter is 12-16nm), pours in the three-necked flask that has condenser, adds the concentrated sulfuric acid that 10.8g mass concentration is 12.6% and the concentrated nitric acid that 2.7g mass concentration is 22.3% The mixed solution was heated to 45°C for ultrasonic dispersion for 1.2h with a power of 300w, washed 5 times with distilled water, and then vacuum-dried at -0.098Mpa and 70°C for 14h to obtain oxidized multi-walled carbon nanotubes.

[0060] (2) Transfer the oxidized multi-walled carbon nanotubes to a three-necked flask connected with a condenser, a vacuum pump, and a separatory funnel placed in an oil bath heating. In the separatory funnel, the concentration after dehydration and deoxidation of 12.0 ...

Embodiment 3

[0064] A method for preparing 3-diethylamino-N,N-diethylpropionamide by amidation, comprising the steps of:

[0065] (1) Measure 4.5g of multi-walled carbon nanotubes (length is 10-20nm, specific surface area is 523m 2 / g, internal diameter is 5-8nm, external diameter is 12-16nm), pours in the three-necked flask that has condensing tube, adds the concentrated sulfuric acid that 9.6g mass concentration is 12.6% and the concentrated nitric acid that 2.4g mass concentration is 22.3% The mixed solution was heated to 50°C for ultrasonic dispersion for 1.5h with a power of 500w, washed with distilled water for 6 times, and then vacuum-dried at -0.098Mpa and 90°C for 16h to obtain oxidized multi-walled carbon nanotubes.

[0066] (2) The dried multi-walled carbon nanotubes are transferred to a three-necked flask connected with a condenser tube, a vacuum pump, and a separatory funnel placed in an oil bath heating. In the separatory funnel, the concentration after dehydration and deoxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com