High-color-rendering-index and high-luminous-efficiency complex-phase fluorescent ceramic for LED/LD illumination, and preparation method thereof

A technology of fluorescent ceramics and high light efficiency, which is applied in energy-saving lighting, chemical instruments and methods, and luminescent materials. effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

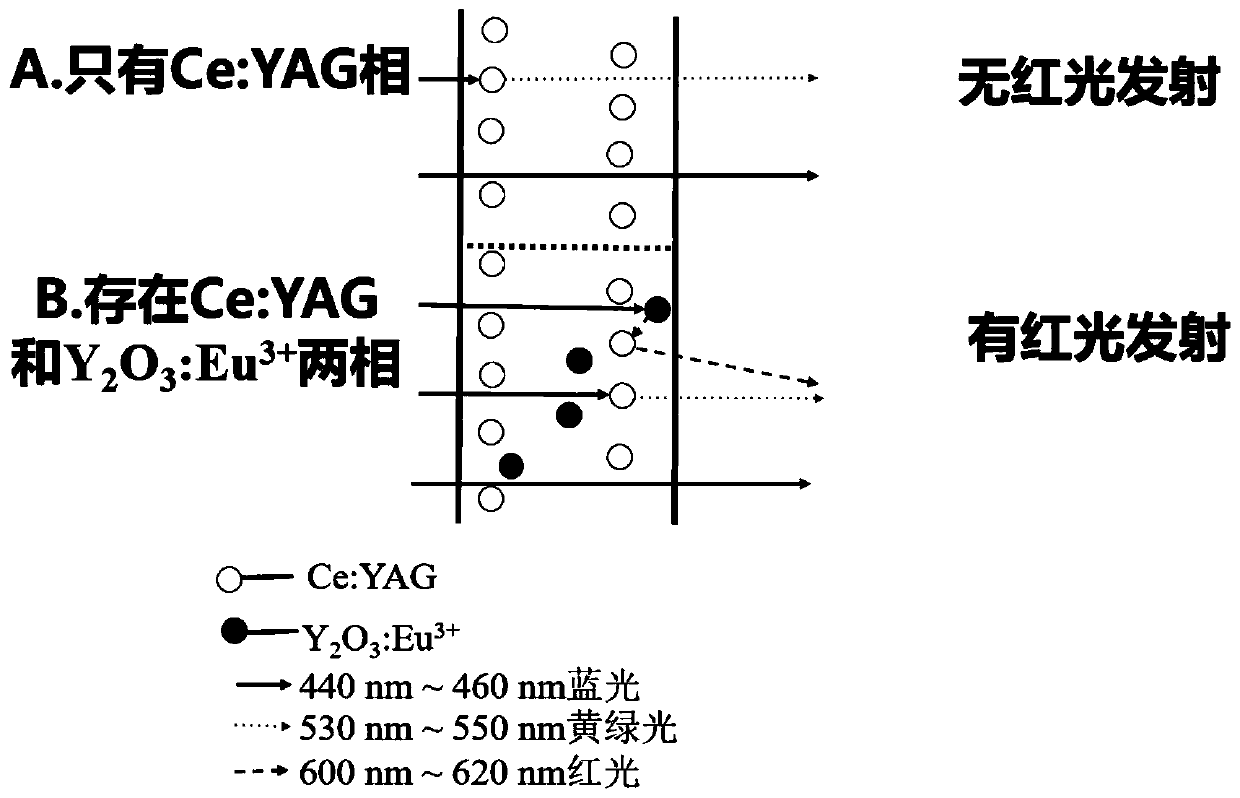

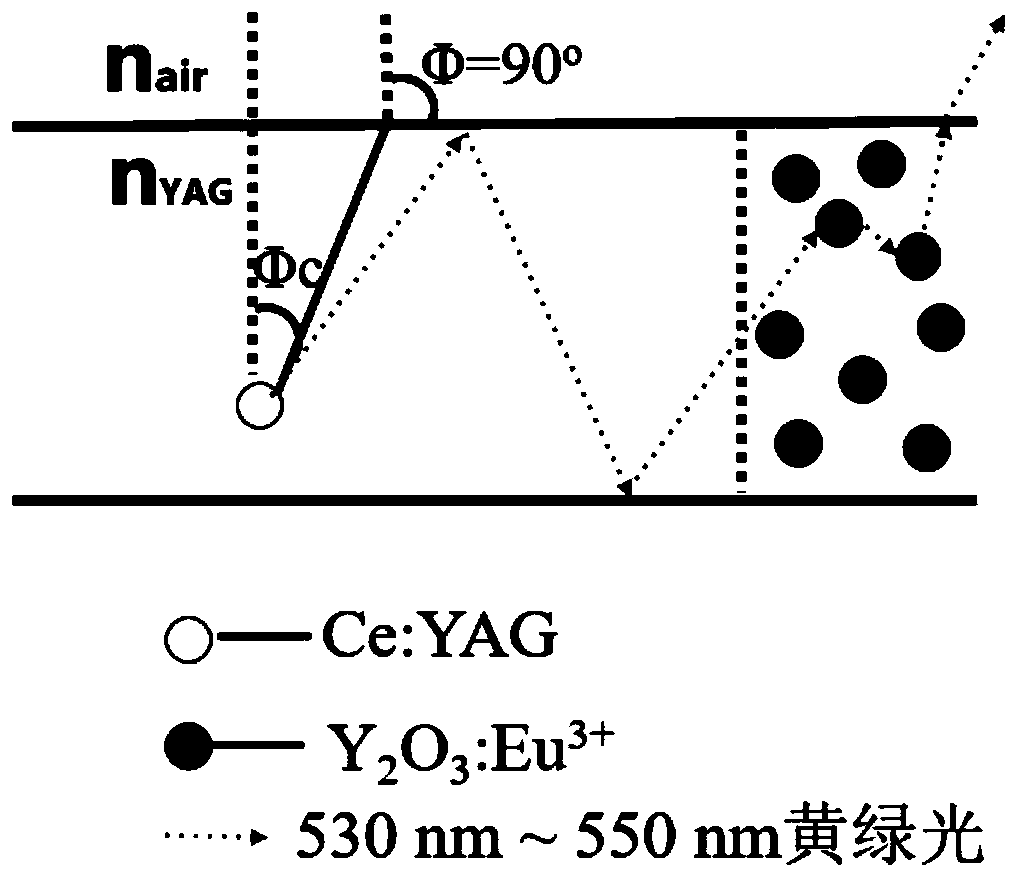

Problems solved by technology

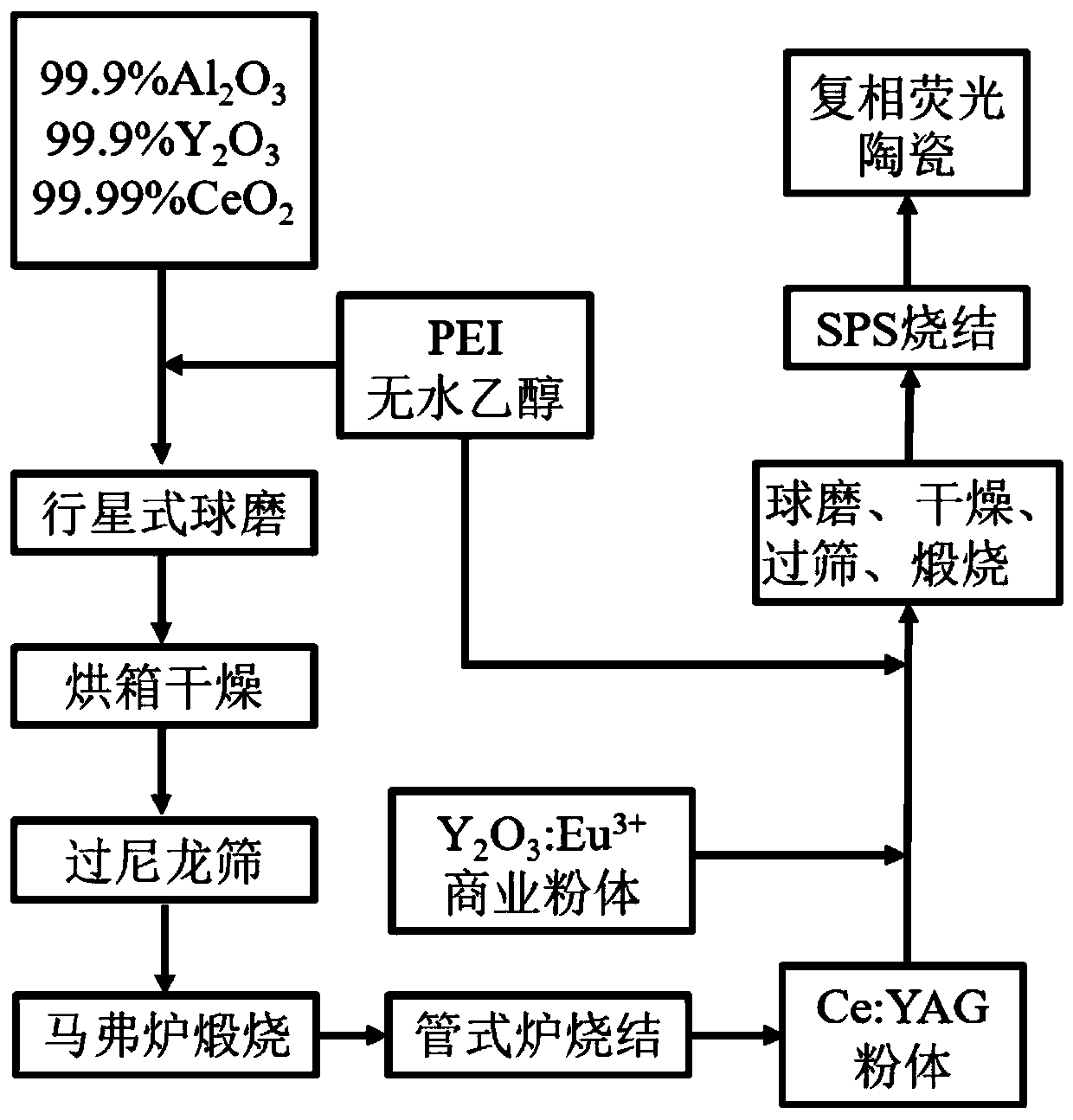

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: prepare 0.9 (Ce 0.005 Y 0.995 ) 3 Al 5 o 12 -0.1 (Eu 0.02 Y 0.98 ) 2 o 3 Composite fluorescent ceramics

[0035] (a) Set the target product quality as 60g, according to (Ce 0.005 Y 0.995 ) 3 Al 5 o 12 Each element stoichiometric ratio in weighs 32.62g of yttrium oxide, 24.67g of aluminum oxide, 0.25g of cerium oxide as raw material to prepare main phase Ce:YAG;

[0036] (b) Mix the raw material powder, 0.3g of polyetherimide, and 60ml of absolute ethanol, add 300g of alumina balls with a diameter of 0.2mm, and carry out planetary ball milling in a nylon ball milling tank at a ball milling speed of 200r / min. The time is 14 hours; the mixed slurry after ball milling is put into a blast drying oven at 55°C and dried for 5 hours, and the dried mixed powder is passed through a 150-mesh sieve, sieved 6 times, and then placed in a muffle furnace for calcination at a temperature of 800°C, holding time 3h, to remove residual organic matter;

[0037] ...

Embodiment 2

[0042] Embodiment 2: prepare 0.8 (Ce 0.007 Y 0.993 ) 3 Al 5 o 12 -0.2 (Eu 0.02 Y 0.98 ) 2 o 3 Composite fluorescent ceramics

[0043] (a) Set the target product quality as 60g, according to (Ce 0.007 Y 0.993 ) 3 Al 5 o 12 Each element stoichiometric ratio in weighs 30.96g of yttrium oxide, 23.46g of aluminum oxide, 0.33g of cerium oxide as raw material to prepare main phase Ce:YAG;

[0044] (b) Mix the raw material powder, 0.5g of polyetherimide, and 100ml of absolute ethanol, add 120g of alumina balls with a diameter of 5mm, and carry out planetary ball milling in a nylon ball mill tank with a ball milling speed of 150r / min and a ball milling time 30h; put the mixed slurry after ball milling into a blast drying oven at 70°C to dry for 10h, and pass the dried mixed powder through a 300-mesh sieve, sieve 10 times, and then place it in a muffle furnace for calcination at a temperature of 900 ℃, holding time 6h, to remove residual organic matter;

[0045] (c) Put t...

Embodiment 3

[0050] Embodiment 3: prepare 0.8 (Ce 0.02 Y 0.98 ) 3 Al 5 o 12 -0.2 (Eu 0.01 Y 0.99 ) 2 o 3 Composite fluorescent ceramics

[0051] (a) Set the target product quality as 60g, according to (Ce 0.02 Y 0.98 ) 3 Al 5 o 12 The stoichiometric ratio of each element in the method takes 30.45g of yttrium oxide, 23.40g of aluminum oxide, and 0.94g of cerium oxide as raw materials to prepare the main phase Ce:YAG;

[0052] (b) Mix the raw material powder, 0.4g of polyetherimide, and 75ml of absolute ethanol, add 180g of alumina balls with a diameter of 0.5mm, and carry out planetary ball milling in a nylon ball mill tank at a ball milling speed of 170r / min. The time is 17 hours; the mixed slurry after ball milling is put into a blast drying oven at 58°C to dry for 7 hours, and the dried mixed powder is passed through a 200-mesh sieve, sieved 7 times, and then calcined in a muffle furnace at a temperature of 800°C, holding time 5h, to remove residual organic matter;

[0053] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com