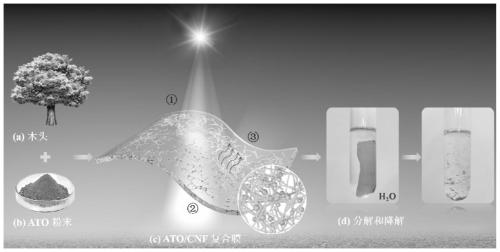

Preparation and application of ATO heat insulation film based on natural cellulose nanofibers

A natural cellulose and nanofiber technology, applied in the field of high-performance ATO thermal insulation film, can solve the problems of organic solvent pollution, non-degradability, non-recyclability, etc., achieve high thermal stability, high degradability and recyclability, eliminate solvent The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Preparation of ATO / CNF Composite Thermal Insulation Film

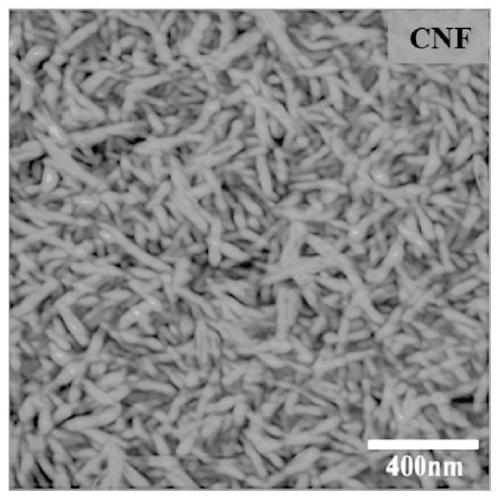

[0062] (1) Take 4g of dry wood pulp board and pulverize, respectively prepare 0.1mol / L sodium carbonate aqueous solution and 0.1mol / L sodium bicarbonate aqueous solution and prepare buffer solution at a volume ratio of 3:2, take 300mL and pour it into the coniferous wood In a beaker on a particle board, disperse well with a hand mixer. Weigh 0.064g TEMPO and 0.4gNaBr respectively, dissolve them and pour them into the coniferous wood slurry, and stir them magnetically. Measure 40mL NaClO with a graduated cylinder and pour it into the slurry to start the reaction. Use 2mol / L sodium hydroxide to adjust the pH to 10.0-11.0. After the color of the solution disappeared and the pH no longer changed, the stirring was continued for another 12 hours. After the reaction is complete, fully filter and wash with deionized water. Then acidify with 1mol / L HCl solution, adjust the pH of the solution to 1 under constant stirri...

Embodiment 2

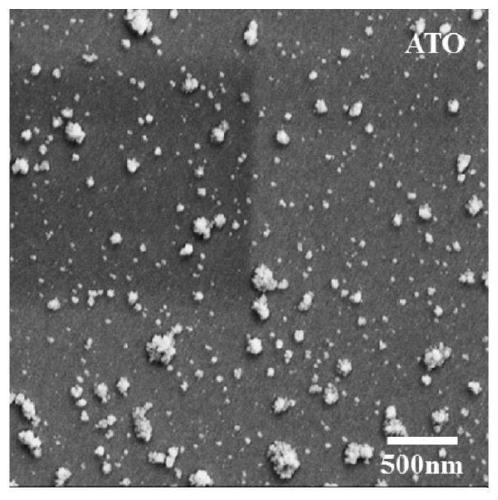

[0066] Consistent with the step of Example 1, the difference is only to change the mixing ratio of the nanoparticle aqueous dispersion and the CNF suspension in the step (2), so that the quality of ATO in the mixed dispersion accounts for 10% of the sum of the ATO and CNF quality, the The obtained composite thermal insulation film is named as 10% ATO / CNF composite thermal insulation film.

Embodiment 3

[0068] Consistent with the step of Example 1, the difference is only to change the mixing ratio of the nanoparticle aqueous dispersion and the CNF suspension in the step (2), so that the quality of ATO in the mixed dispersion accounts for 20% of the sum of the ATO and CNF masses. The obtained composite thermal insulation film is named as 20% ATO / NFC composite thermal insulation film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com