Oil-in-water type environment-friendly spray adhesive and preparation method thereof

An oil-in-water type, environmentally friendly technology, applied in the direction of adhesives, adhesive types, rosin adhesives, etc., can solve the problems of poor antifreeze performance of water-based spray adhesives, high cost of raw materials, and volatile organic solvents, etc., to achieve Improve frost resistance and low temperature stability, facilitate spraying operation, and reduce the effect of organic solvent components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The oil-in-water type environmental protection spray glue of this embodiment includes 50 parts of oil phase, 10 parts of compound emulsifier, 50 parts of deionized water, 1 part of polyether modified polysiloxane defoamer, 1 part of diethylene glycol Glycol dibenzoate, 2 parts stabilizer (1 part methylcellulose and 1 part ethylcellulose); of which,

[0031] The composition of the oil phase comprises 10 parts of thermoplastic styrene-butadiene rubber (5 parts of Yuehua 1401, 5 parts of Yuehua 1301); 12 parts of tackifying resin (5 parts of rosin glyceride 138, 5 parts of rosin, 2 parts of terpene phenolic resin 803L); 100 parts of mixed solvent (50 parts of methyl acetate, 30 parts of ethyl acetate, 20 parts of absolute ethanol).

[0032] The composition of the compound emulsifier comprises 3 parts of sodium dodecylbenzenesulfonate, 3 parts of alkyl alcohol ether phosphate and 2 parts of alkylphenol polyoxyethylene ether.

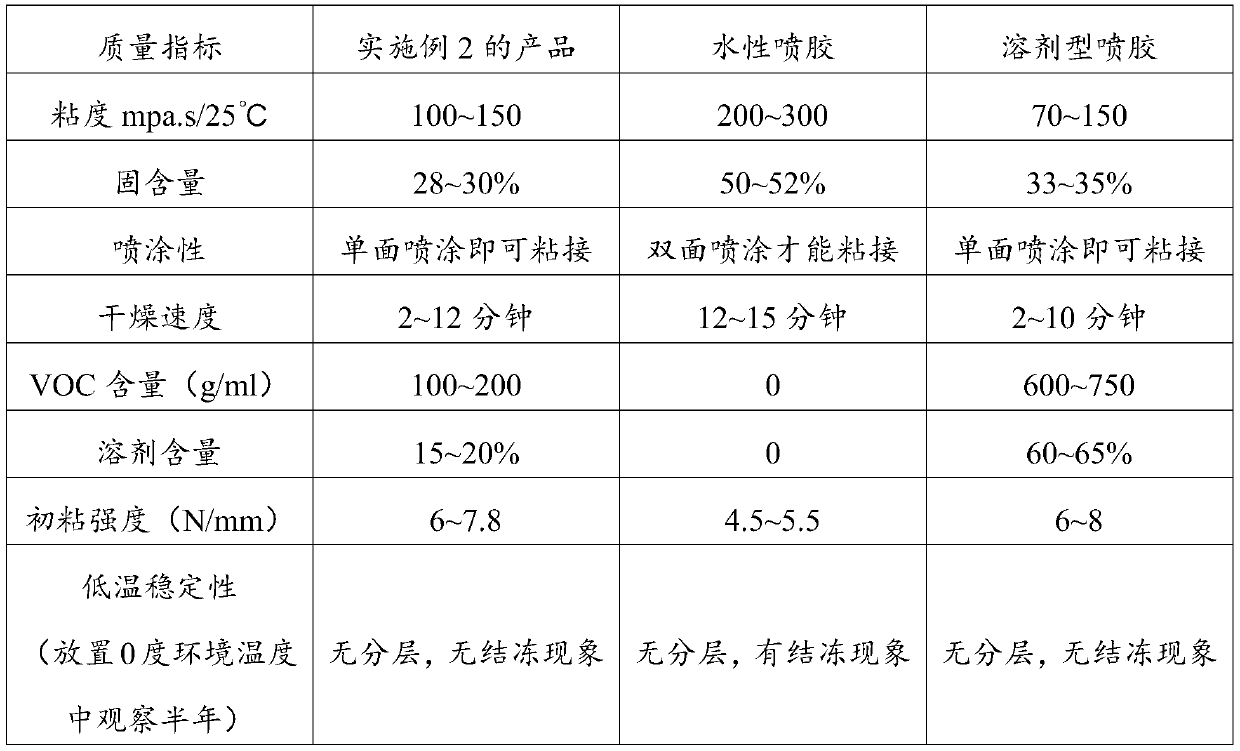

Embodiment 2

[0034] The oil-in-water type environmental protection spray glue of this embodiment includes 80 parts of oil phase, 30 parts of compound emulsifier, 80 parts of deionized water, 1.5 parts of polyether modified polysiloxane defoamer, 2 parts of diethylene glycol Glycol dibenzoate, 3 parts stabilizer (1.5 parts methylcellulose and 1.5 parts ethylcellulose); of which,

[0035] The composition of described oil phase comprises 15 parts of thermoplastic styrene-butadiene rubbers (7.5 parts of Yuehua 1401, 7.5 parts of Yuehua 1301); 803L); 180 parts of mixed solvent (80 parts of methyl acetate, 60 parts of ethyl acetate, 40 parts of absolute ethanol).

[0036] The compound emulsifier comprises 5 parts of sodium dodecylbenzenesulfonate, 5 parts of alkyl alcohol ether phosphate and 5 parts of alkylphenol polyoxyethylene ether.

Embodiment 3

[0038] The oil-in-water type environmental protection spray glue of this embodiment includes 100 parts of oil phase, 50 parts of compound emulsifier, 100 parts of deionized water, 2 parts of polyether modified polysiloxane defoamer, 3 parts of diethylene glycol Glycol dibenzoate, 5 parts stabilizer (3 parts methylcellulose and 2 parts ethylcellulose); of which,

[0039] The composition of described oil phase comprises 20 parts of thermoplastic styrene-butadiene rubbers (10 parts of Yuehua 1401, 10 parts of Yuehua 1301); 30 parts of tackifying resins (8 parts of rosin glyceride 138, 16 parts of rosin, 6 parts of terpene phenolic resins 803L); 230 parts of mixed solvent (100 parts of methyl acetate, 80 parts of ethyl acetate, 50 parts of absolute ethanol).

[0040] The compound emulsifier comprises 10 parts of sodium dodecylbenzenesulfonate, 8 parts of alkyl alcohol ether phosphate and 6 parts of alkylphenol polyoxyethylene ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com