Alkaline pad dyeing method for nylon 56 and cellulose fiber blended fabric

A technology for cellulose fibers and dyeing methods, applied in dyeing methods, textiles and papermaking, etc., can solve problems such as lengthy processes, inconsistent fiber color and light, and difficulty in dyeing blended fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

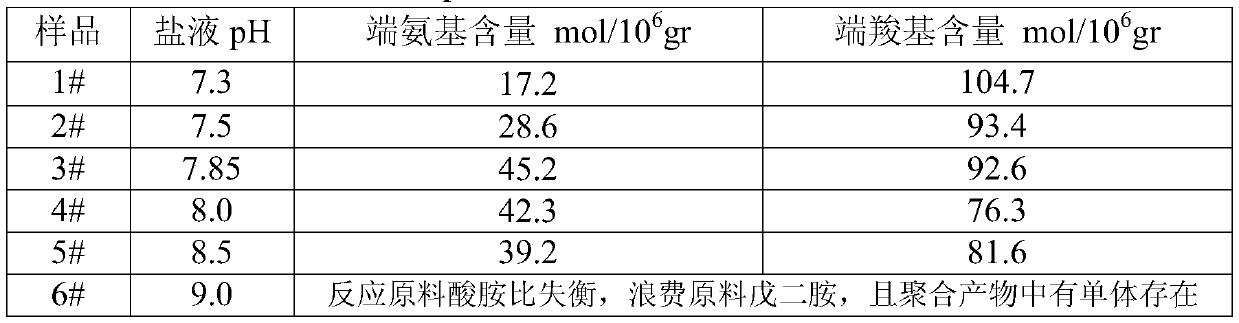

[0128] Embodiment 1, adopt vat dye suspension alkaline dyeing solution to pad dye nylon 56 fiber and cotton blended fabric

[0129] First take nylon 56 / cotton (60 / 40) blended fabric, 10cm×10cm, dyeing solution 100mL, prepare dyeing solution with vat blue RSN dye of 30g / L, add 3g / L slow dyeing agent NLJ, 5g / L in the dyeing solution salt to adjust the pH of the dye solution to 7.8. The dyeing liquid configuration is completed. At room temperature, the blended fabric is soaked in the dyeing liquid for 5 minutes by means of one dipping and one padding. After rolling the reducing solution (preparation of the reducing solution: 34g / L sodium hydroxide, 20g / L sodium hydroxide, bath ratio 1:30), the residual rolling rate is about 70%. After steaming at 100°C for 5 minutes, wash once with water at room temperature , oxidized at 40°C (1g / L 30% hydrogen peroxide, 2min), took out the sample and washed it once in hot water at 60°C and once in cold water at room temperature, and the pad dye...

Embodiment 2

[0133] Embodiment 2, adopt reactive dye basic pad dyeing nylon 56 fiber and viscose fiber blended fabric

[0134] First, take nylon 56 / viscose (55 / 45) blended fabric, 10cm × 10cm, dyeing solution 100mL, prepare dyeing solution with 15g / L Anuosu Brilliant Blue RV 100% dye, add retarder JV-905 5g / L, Yuanming powder 10g / L, pH value of the dyeing solution is 8.0. The dyeing liquid configuration is completed. At room temperature, the blended fabric is soaked in the dyeing liquid for 3 minutes by two dipping and two padding methods. The padding speed is controlled to 45m / min, the padding pressure is 0.23MPa, and the liquid rolling rate is about 90%. One immersion and one rolling color fixing solution (preparation of 100mL color fixing solution: add 15g / L sodium carbonate and treat for 5 minutes) to control the excess rate at about 75%. After the color fixing sample is baked at 95°C for 10 minutes, take it out in the Wash once in hot water at 85°C, once in cold water at room temper...

Embodiment 3

[0139] Embodiment 3, adopt direct dyestuff basic pad dyeing nylon 56 fiber and hemp fiber blended fabric

[0140] First, take nylon 56 / hemp (50 / 50) blended fabric, 10cm×10cm, dye liquor 100mL, prepare dye liquor with 40g / L direct turquoise blue B2RL dye, add leveling agent GC-230 5g / L in the dye liquor , Salt 8g / L, adjust the pH value of the dye solution to 8.0. The dyeing liquid configuration is completed. At room temperature, the blended fabric is soaked in the dyeing liquid for 5 minutes by two dipping and two padding methods. The padding speed is controlled to 35m / min. After steaming at 100°C for 5 minutes, take out the sample and wash it once in hot water at 60°C and once in cold water at room temperature, to complete the pad dyeing.

[0141] The apparent homochromaticity of the blended fabric after dyeing is shown in Table 6. The experimental data of direct dye pad dyeing test are shown in Table 4.

[0142] Table 4 Direct dyeing test experimental data

[0143]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com