Preparation method of graphene

A graphene and lignin technology, applied in the field of carbon material production technology, can solve the problems of large uncertainty, high cost, low efficiency, etc., and achieve the effects of good electrochemical performance, good reference significance, and high academic value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

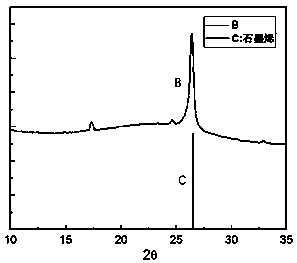

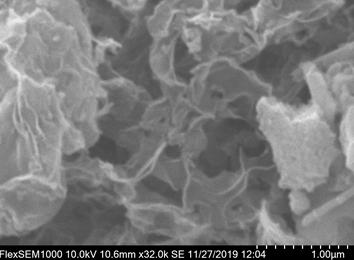

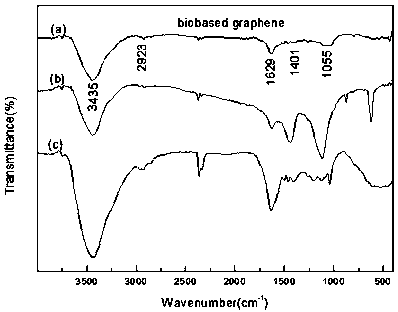

[0028] In Example 1, at room temperature, 6g of lignin, 2.5g of iron nitrate nonahydrate and 6ml of tetrahydrofuran were added to 100ml of deionized water, heated in a water bath at 80°C for 8 hours, and dried in a blast drying oven until All converted to precursors. Transfer the obtained precursor to a porcelain sample boat and put it in a solid tube furnace, raise it from room temperature at 5℃ / min to 180° and keep it for 1 hour, then continue to heat it up to 900° and keep it for 3 hours, then 5℃ / min is reduced to room temperature, and nitrogen protection is introduced at a constant speed during the calcination process at a rate of 60ml / min. The calcined sample was taken out and rinsed with 1mol / L dilute hydrochloric acid until no more bubbles were generated and the supernatant was clear. After standing for 24 hours, change the hydrochloric acid and heat it in a 80° water bath for 3 hours, and ultrasonicate for 2 hours after cooling. The solid was obtained by centrifugatio...

Embodiment 2

[0029] In Example 2, at room temperature, 6g of lignin, 2.5g of iron nitrate nonahydrate and 6ml of tetrahydrofuran were added to 100ml of deionized water, heated in a water bath at 80°C for 8 hours, and dried in a blast drying oven until All converted to precursors. Transfer the obtained precursor to a porcelain sample boat and put it in a solid tube furnace, raise it from room temperature at 5℃ / min to 180° and keep it for 1 hour, then continue to heat it up to 800° and keep it for 3 hours, then 5℃ / min is reduced to room temperature, and nitrogen protection is introduced at a constant speed during the calcination process at a rate of 60ml / min. The calcined sample was taken out and rinsed with 1mol / L dilute hydrochloric acid until no more bubbles were generated and the supernatant was clear. After standing for 24 hours, change the hydrochloric acid and heat it in a 80° water bath for 3 hours, and ultrasonicate for 2 hours after cooling. The solid was obtained by centrifugatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com