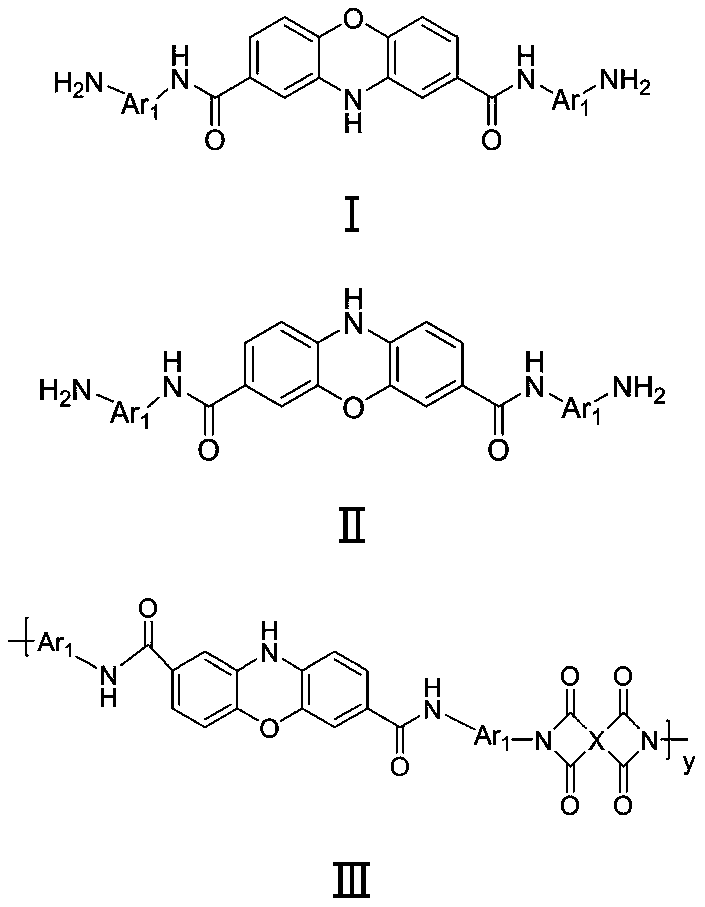

Diamine containing phenoxazine and amide structures and polyimide thereof

A polyimide and phenoxazine technology, applied in the field of material science, can solve the problems of limiting the wide application of polyimide, insufficient antibacterial properties, easy to break and fall off, etc., and achieve high glass transition temperature and thermal stability. , improve functional diversity, and promote the effect of close stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

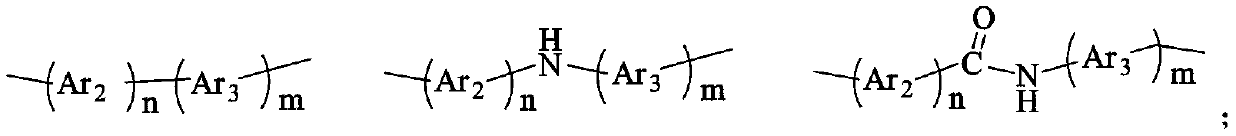

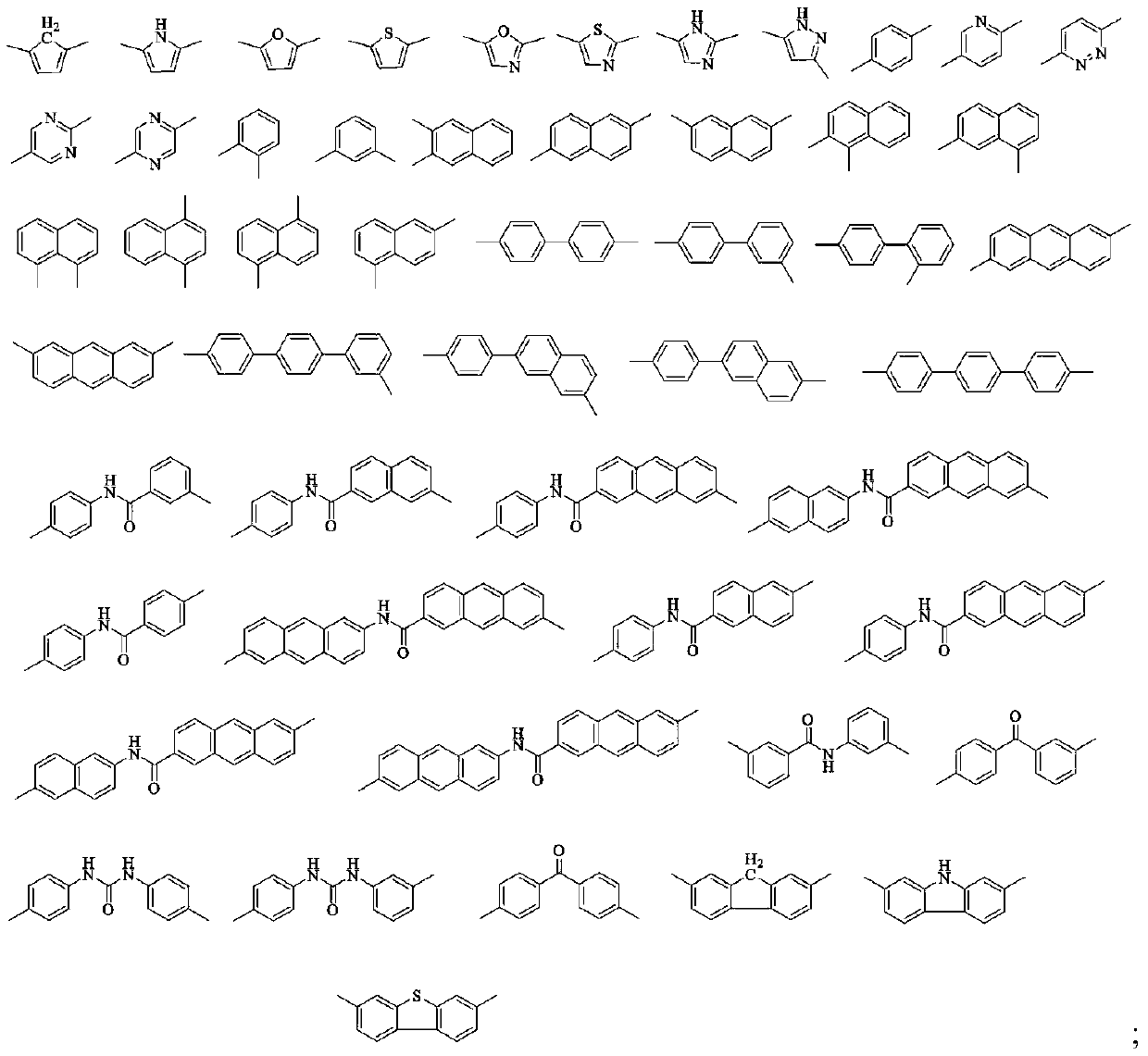

Method used

Image

Examples

Embodiment 1

[0047] This example provides

[0048]Synthesis of N3,N7-bis(4-aminophenyl)-10H-phenoxazine-3,7-dicarboxamide:

[0049]

[0050] (1) Synthesis of intermediate 10H-phenoxazine-3,7-dicarbonitrile:

[0051] Add 3.41g (0.01mol) of 3,7-dibromo-10H-phenoxazine, 4.478g (0.05mol) of cuprous cyanide, and 50ml of dry NMP into a 500ml three-necked flask, reflux at 140°C for 24h, and then add H 2 O (180mL), HCl (60mL) and FeCl3 (4.19g, 25.8mmol) were poured into the reaction solution and stirred for 1h, cooled to room temperature, filtered to obtain a brown precipitate, and washed with water, and the resulting solid was re-dissolved in dichloromethane and washed with water, Removal of the solvent under reduced pressure gave the crude product as a brown solid which was triturated with methanol to give the intermediate. The intermediate structure is as follows:

[0052]

[0053] (2) Synthesis of intermediate 10H-phenoxazine-3,7-dicarboxylic acid:

[0054] Add 2.33g (0.01mol) of 10H...

Embodiment 2

[0065] This example provides the synthesis of N3, N7-bis(5-aminothiophen-2-yl)dibenzo[b,d]furan-3,7-dicarboxamide:

[0066]

[0067] (1) Synthesis of intermediate 10H-phenoxazine-2,7-dicarbonitrile:

[0068] Add 3.41g (0.01mol) of 2,7-dibromo-10H-phenoxazine, 4.478g (0.05mol) of cuprous cyanide, and 50ml of dry NMP into a 500ml three-necked flask, reflux at 140°C for 24h, and then add H 2 O (180mL), HCl (60mL) and FeCl3 (4.19g, 25.8mmol) were poured into the reaction solution and stirred for 1h, cooled to room temperature, filtered to obtain a brown precipitate, and washed with water, and the resulting solid was re-dissolved in dichloromethane and washed with water, Removal of the solvent under reduced pressure gave the crude product as a brown solid which was triturated with methanol to give the intermediate. The intermediate structure is as follows:

[0069]

[0070] (2) Synthesis of intermediate 10H-phenoxazine-2,7-dicarboxylic acid:

[0071] Add 2.33g (0.01mol) of...

Embodiment 3

[0082] This example provides N2,N8-bis(7-aminodibenzo[b,d]furan-3-yl)-10H-phenoxazine-2,8-dicarboxamide:

[0083]

[0084] (1) Synthesis of intermediate 10H-phenoxazine-2,8-dicarbonitrile:

[0085] Add 3.41g (0.01mol) of 2,8-dibromo-10H-phenoxazine, 4.478g (0.05mol) of cuprous cyanide, and 50ml of dry NMP into a 500ml three-necked flask, reflux at 140°C for 24h, and then add H 2 O (180mL), HCl (60mL) and FeCl 3 (4.19g, 25.8mmol) was poured into the reaction solution and stirred for 1h, cooled to room temperature, filtered to obtain a brown precipitate, and washed with water, the resulting solid was re-dissolved in dichloromethane and washed with water, and the solvent was removed under reduced pressure to obtain the crude product as a brown solid , which was triturated with methanol to afford the intermediate. The intermediate structure is as follows:

[0086]

[0087] (2) Synthesis of intermediate 10H-phenoxazine-2,8-dicarboxylic acid:

[0088]Add 2.33g (0.01mol) of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com