Waterborne two-component epoxy composition as well as preparation method and application thereof

An epoxy composition, water-based epoxy technology, applied in the direction of epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of paint film defects, low degree of curing reaction, and decline in anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

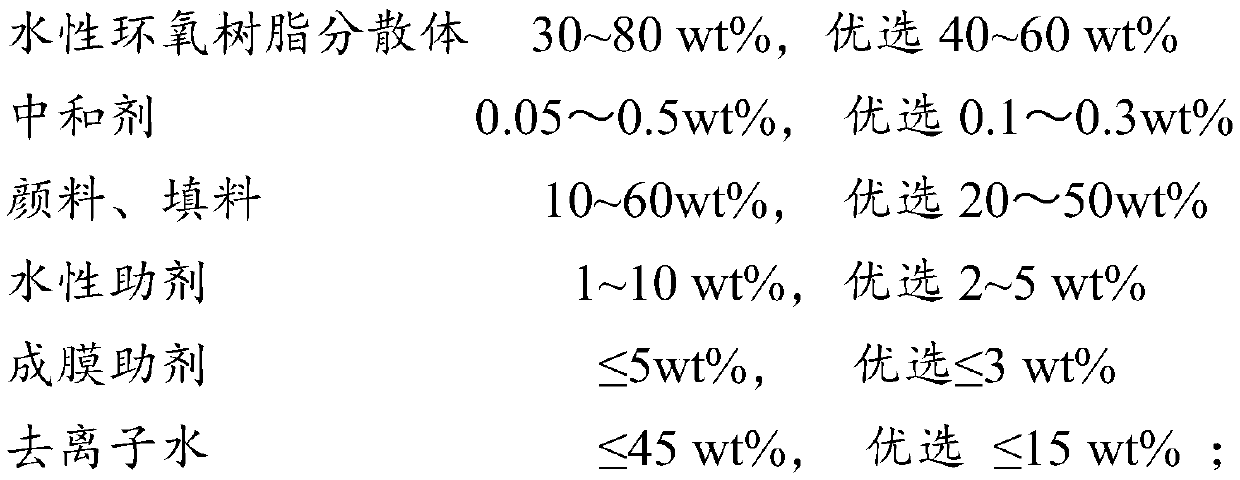

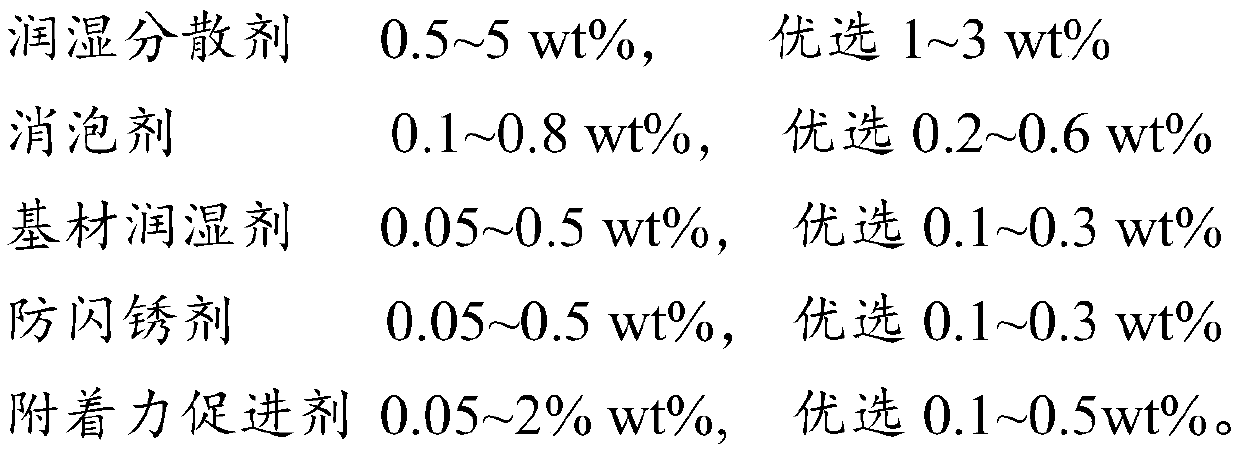

Method used

Image

Examples

Embodiment 1

[0075]Add 800g of anhydrous polyethylene glycol (Mw=6000) into the reaction flask, heat to 90°C to dissolve the polyethylene glycol, add 50g of hexahydrophthalic anhydride, raise the temperature to 140°C, and react for 2 hours. Continue to add 280g of epoxy resin E20 (that is, the third epoxy resin, epoxy equivalent 500) and 12g of triphenylphosphine to the reactant, continue to keep warm at 140°C, react for 2 hours, and cool to room temperature. Add 1900g epoxy resin E20 (epoxy equivalent 500), 815g epoxy resin E12 (epoxy equivalent 830) and 1500g ethylene glycol butyl ether in the reactant, E20 and E12 are as the first epoxy resin, fully After mixing, keep warm at 70°C, keep the speed of mechanical stirring at 1000 rpm, slowly add 2350g of deionized water to the mixture, and cool to room temperature to obtain a water-based epoxy resin dispersion with a solid content of about 50%. Body, referred to as dispersion I. Dispersion I had an epoxy equivalent weight of 600-700 (base...

Embodiment 2

[0077] Similar to Example 1, add 800g of anhydrous polyethylene glycol (Mw=6000) to the reaction flask, heat to 90°C to dissolve the polyethylene glycol, add 50g of hexahydrophthalic anhydride, raise the temperature to 130°C, and react for 2 hours . Continue to add 280g of epoxy resin E20 (500 epoxy equivalent) and 12g of triphenylphosphine into the reactant, continue to keep warm at 130°C, react for 2 hours, and cool to room temperature. Add 1500g of epoxy resin E20, 1215g of epoxy resin E12 (epoxy equivalent 830) and 1500g of ethylene glycol butyl ether in the reactant, after fully mixing, keep the temperature at 70°C, and the rotating speed of mechanical stirring remains at 800 rpm Minutes, slowly add 2350 g of deionized water dropwise to the mixture, and cool to room temperature to obtain aqueous epoxy resin dispersion II with a solid content of about 50%. Dispersion II has an epoxy equivalent weight of 650-750 (based on solids) and a solvent content of 19.5%.

Embodiment 3

[0079] Add 600g of anhydrous polyethylene glycol (Mw=6000) into the reaction flask, heat to 90°C to dissolve the polyethylene glycol, add 37g of hexahydrophthalic anhydride, raise the temperature to 150°C, and react for 2 hours. Continue to add 210g of epoxy resin E20 (500 epoxy equivalent) and 10g of triphenylphosphine into the reactant, keep warm at 150°C, react for 2 hours, and cool to room temperature. Add 3000g of epoxy resin E20 and 1150g of ethylene glycol butyl ether to the reactant, mix well, keep warm at 70°C, keep the speed of mechanical stirring at 1200 rpm, and slowly drop 2700g of deionized water into the mixture , cooled to room temperature, the aqueous epoxy resin dispersion III with a solid content of about 50% can be obtained. Dispersion III has an epoxy equivalent weight of 550-650 (based on solid content), and a solvent content of 15.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com