Preparation method of polydopamine modified polyethersulfone imprinted composite membrane

A technology of polydopamine and polyethersulfone membranes, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problem that phenol cannot be separated specifically, achieve good selectivity, increase activity and adhesion, and absorb A large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The material used in the present invention is as follows:

[0029] Glucose: solid solid, purity 99%; γ-methacryloxypropyltrimethoxysilane: liquid liquid, purity 99%; absolute ethanol: liquid liquid, purity 99.7%; deionized water: liquid liquid, purity 99.99%; 4-vinylpyridine: liquid liquid, purity 99%; ethylene glycol dimethacrylate: liquid liquid, purity 99.9%; phenol: solid solid, purity 99.5%; toluene: liquid liquid, purity 99.5%; Azobisisobutyronitrile: solid solid, purity 99.5%; Dopamine: solid solid, purity 99.5%; Tris: solid solid, purity 99.9%.

[0030] The polyethersulfone membrane was purchased from Merck Millipore, with a diameter of 13 mm and a membrane pore size of 0.45 μm.

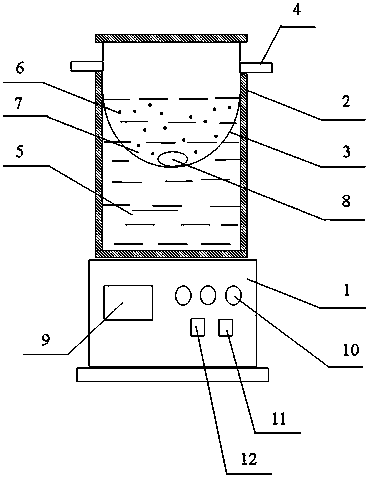

[0031] Such as figure 1 As shown, the position and connection relationship of each part must be correct, and the installation should be firm.

[0032] The preparation of the polydopamine-modified polyethersulfone imprinted composite membrane was carried out in a single-necked flask ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

| Equilibrium adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com