Carbon-supported nickel oxide modified platinum rhodium nanorod electrocatalyst for alkaline hydrogen evolution reaction and preparation method and application thereof

An electrocatalyst, nickel oxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of incapable of large-scale production, complicated preparation process and synthesis cost Advanced problems, to achieve the effect of easy large-scale production, simple and easy preparation process, and low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Preparation of nickel oxide-modified platinum-rhodium nanorods

[0045] Pt(acac) 2 (10.0mg), Ni(acac) 3 (6.9 mg), Rh(acac) 3 (1.0 mg), Mo(CO) 6 (10.0mg), DDAB (30.0mg), add 5mL oleylamine. The air in the reactor was replaced with a flow of argon for 10 minutes. After covering the reaction cap, the reactor was ultrasonicated for half an hour to obtain a transparent and uniform solution. Then the temperature was raised to 180° C. within half an hour, then kept at a temperature of 8 hours, and then naturally cooled to room temperature. After the reaction, the product was collected by centrifugation, then cyclohexane and ethanol (1mL:5mL) solution was added to redisperse, and the product was collected by centrifugation again, and the operation was repeated to clean the organic matter adsorbed on the surface of the catalyst. Finally, the obtained catalyst was dispersed in cyclohexane solution for later use.

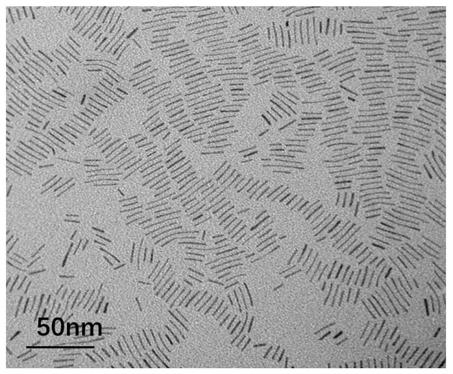

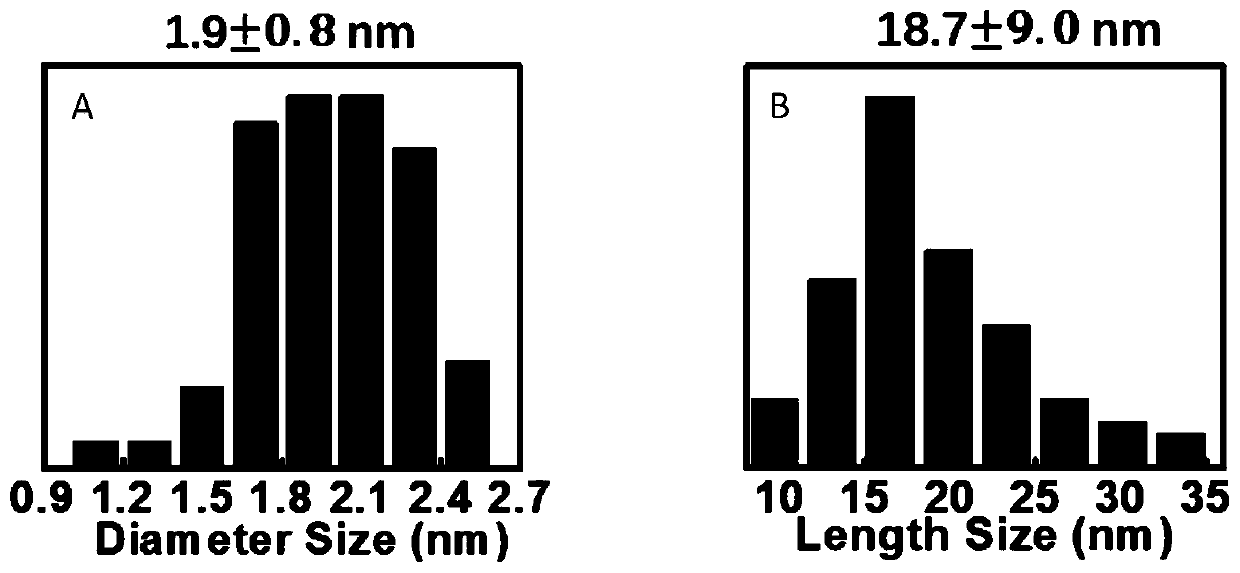

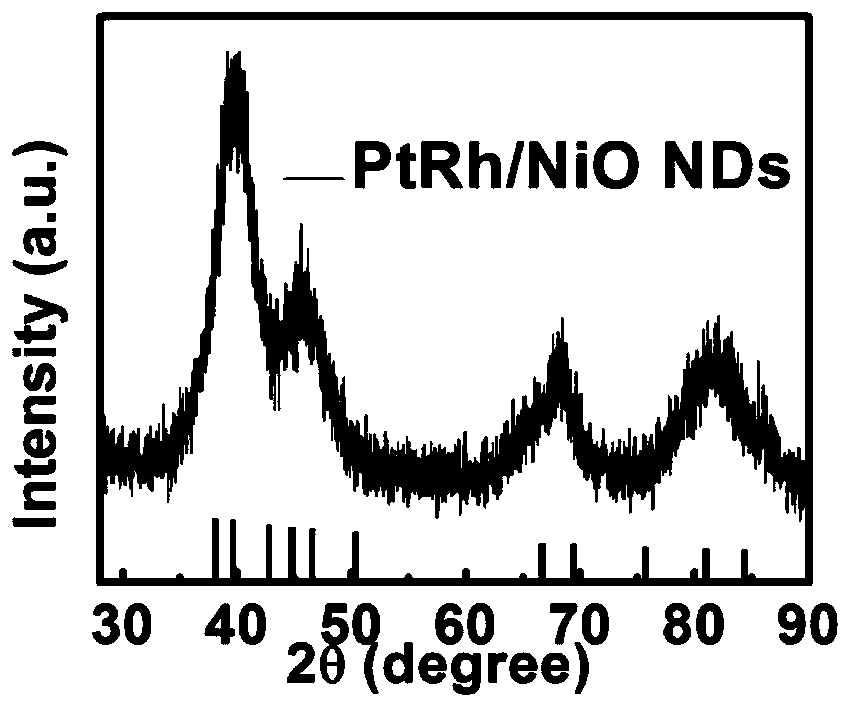

[0046] Such as figure 1 , TEM results showed that the ...

Embodiment 2

[0056] (1) Preparation of nickel oxide-modified platinum nanorods

[0057] Pt(acac) 2 (10.0mg), Ni(acac) 3 (6.9 mg), Mo(CO) 6 (10.0mg), DDAB (30.0mg), add 5mL oleylamine. The air in the reactor was replaced with a flow of argon for 10 minutes. After covering the reaction cap, the reactor was ultrasonicated for half an hour to obtain a transparent and uniform solution. Then the temperature was raised to 180° C. within half an hour, then kept at a temperature of 8 hours, and then naturally cooled to room temperature. After the reaction, the product was collected by centrifugation, then cyclohexane and ethanol (1mL:5mL) solution was added to redisperse, and the product was collected by centrifugation again, and the operation was repeated to clean the organic matter adsorbed on the surface of the catalyst. Finally, the obtained catalyst was dispersed in cyclohexane solution for later use.

[0058] Such as Figure 5 , TEM results show that the product morphology obtained is ...

Embodiment 3

[0063] (1) Preparation of nickel oxide-modified platinum nanorods

[0064] Pt(acac) 2 (10.0mg), Ni(acac) 3 (4.6 mg), Mo(CO) 6 (10.0mg), DDAB (30.0mg), add 5mL oleylamine. The air in the reactor was replaced with a flow of argon for 10 minutes. After covering the reaction cap, the reactor was ultrasonicated for half an hour to obtain a transparent and uniform solution. Then the temperature was raised to 180° C. within half an hour, then kept at a temperature of 8 hours, and then naturally cooled to room temperature. After the reaction, the product was collected by centrifugation, then cyclohexane and ethanol (1mL:5mL) solution was added to redisperse, and the product was collected by centrifugation again, and the operation was repeated to clean the organic matter adsorbed on the surface of the catalyst. Finally, the obtained catalyst was dispersed in cyclohexane solution for later use.

[0065] (2) Preparation of carbon-supported nickel oxide-modified platinum nanorods

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com