Hollow tubular graphite-phase carbon nitride photocatalyst containing nitrogen defects, preparation method and applications thereof

A carbon nitride light and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effect of increasing the migration rate, expanding the optical absorption range, and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A hollow tubular graphite phase carbon nitride photocatalyst containing nitrogen defects, the preparation method of which comprises the following steps:

[0038] (1) Weigh 4.0g of melamine into 4 groups of beakers, add 60mL of deionized water respectively, ultrasonically disperse evenly, put them into a water bath and stir while performing water bath reaction, the stirring speed is controlled at 500rpm, and the temperature of the water bath is controlled at 85°C Mix around until the melamine is completely dissolved to a homogeneous solution.

[0039] (2) Quickly transfer the solution after the water bath obtained in step (1) to a 100mL autoclave liner, cover the lid, put it into the autoclave for compaction and tighten the lid of the autoclave, transfer it to the oven, and adjust the temperature to 180 ℃ and kept for 24h, after natural cooling, the obtained product was washed several times with deionized water and ethanol to neutrality, filtered (ie suction filtration),...

experiment example 1

[0050] The hollow tubular carbon nitride and carbon nitride monomers of Comparative Example 1 and Comparative Example 2 and the hollow tubular graphite phase carbon nitride photocatalyst containing nitrogen defects in Example 1 were scanned by an electron microscope.

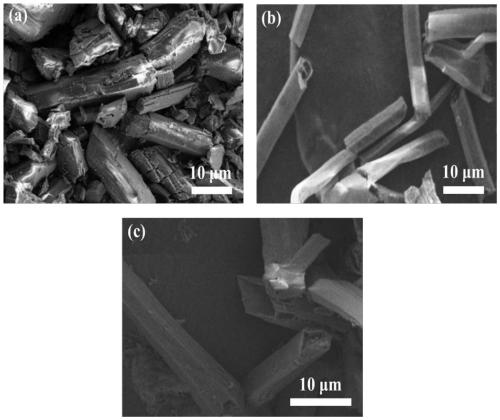

[0051] figure 1 Be respectively the scanning electron microscope (SEM) picture of the hollow tubular carbon nitride of the present invention comparative example 1, comparative example 2, embodiment 1, carbon nitride monomer and the hollow tubular graphite phase carbon nitride photocatalyst of nitrogen defect, Where (a) is CN, (b) is TCN, and (c) is ND-TCN-10.

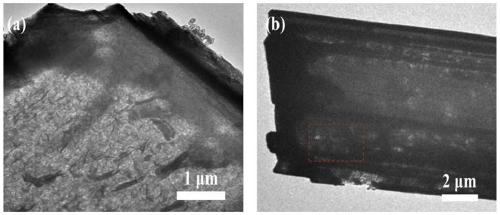

[0052] figure 2 It is a transmission electron microscope (TEM) picture of ND-TCN-10 in Example 1 of the present invention.

[0053] From figure 1 It can be seen that the carbon nitride monomer exhibits an obvious block structure and has a small specific surface area; the hollow tubular carbon nitride presents a hollow tubular structure, which greatly ...

experiment example 2

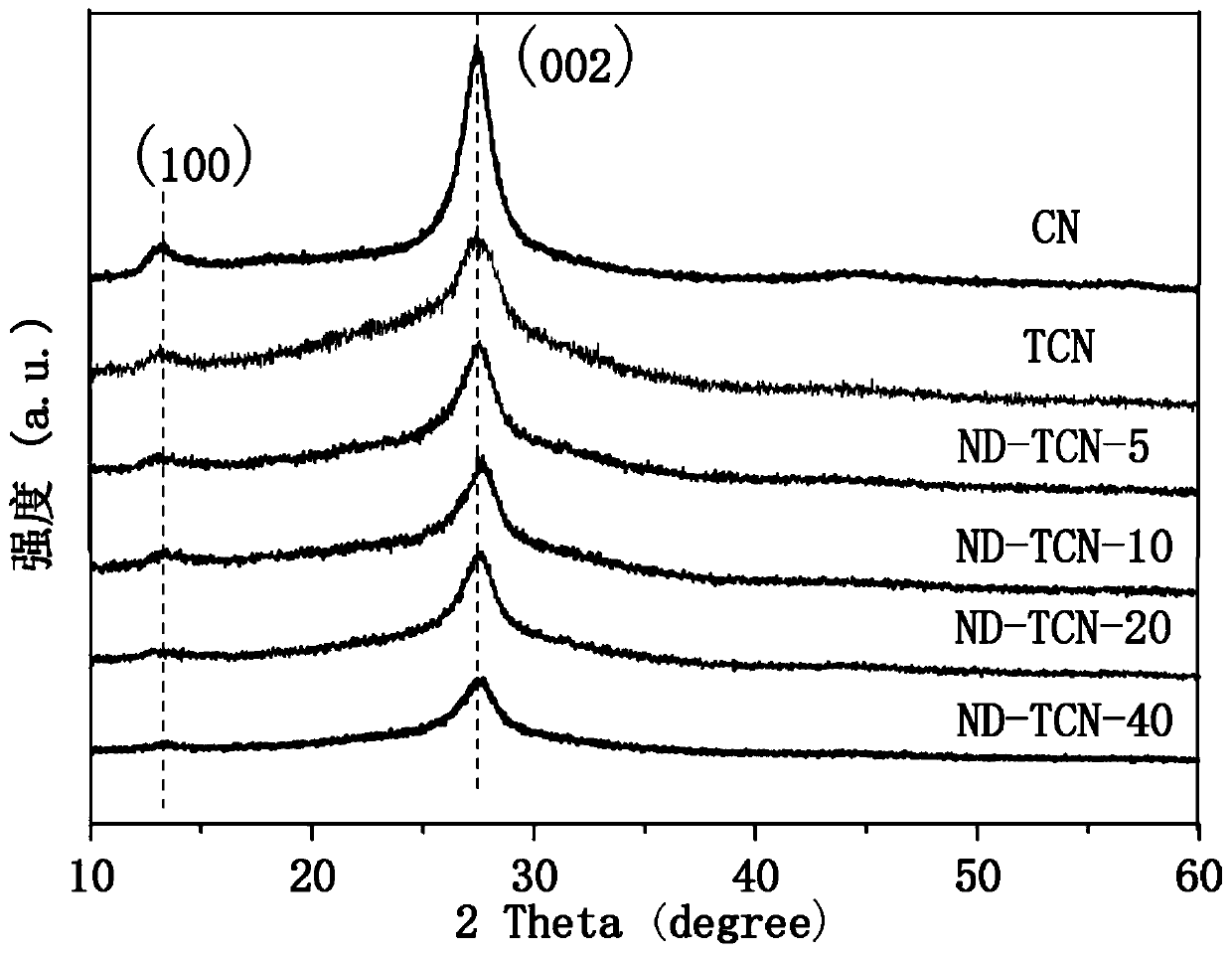

[0056] The hollow tubular carbon nitride, carbon nitride monomer, and hollow tubular graphite phase carbon nitride photocatalyst containing nitrogen defects in Comparative Example 1, Comparative Example 2 and Example 1 were subjected to X-ray scanning.

[0057] image 3 It is the X-ray diffraction spectrum (XRD) contrast figure of the hollow tubular carbon nitride of the present invention comparative example 1, comparative example 2, carbon nitride monomer and the hollow tubular graphite phase carbon nitride photocatalyst of nitrogen defect of embodiment 1 . It can be seen from the figure that two characteristic peaks appearing at 13.1° and 27.5° are respectively attributed to the XRD diffraction peaks of the (100) and (002) crystal planes of graphitic carbon nitride, indicating that the prepared product is indeed g-C 3 N 4 . Compared with carbon nitride monomer (CN), the two signal peaks of hollow tubular carbon nitride (TCN) are significantly weakened, but slightly higher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com