Simple method for loading ultrafine nano zero-valent iron on porous material

A porous material and ultra-fine nano technology, applied in chemical instruments and methods, other chemical processes, physical/chemical process catalysts, etc., can solve problems such as increasing operational complexity, and achieve easy operation, small particle size, and increased surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 : The preparation method of the porous material loaded with ultrafine nanometer zero-valent iron of the present invention

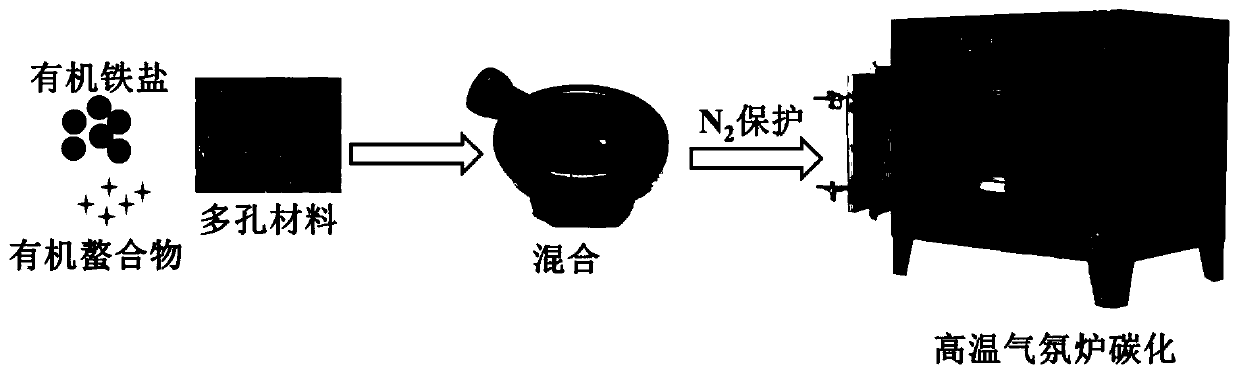

[0043] The synthesizing schematic diagram of the porous material loaded with ultrafine nanometer zero valent iron provided by the present invention is as follows figure 1 Shown, its specific preparation method is:

[0044] First, weigh a certain proportion of organic iron salt and organic ligands and mix them with porous materials: for powdery porous materials, they can be directly mixed with organic iron salts and ligands in a mortar; for bulk porous materials, organic The solid powder of iron salts and ligands sticks to the surface of the block material, and can also be sprinkled in the middle of the material. The obtained mixed solid is put into a crucible, and heated at a high temperature of 700-1100° C. for 1-4 hours under the protection of an inert gas to obtain a porous material adsorbent / catalyst loaded with ultrafine particle ...

Embodiment 2

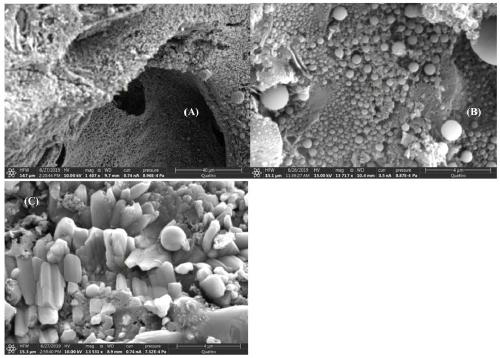

[0045] Example 2 : Structural characterization of the porous material loaded with ultrafine nanometer zero-valent iron of the present invention

[0046] This embodiment is the structural characterization of the porous material loaded with ultrafine nano-zero valent iron, as follows:

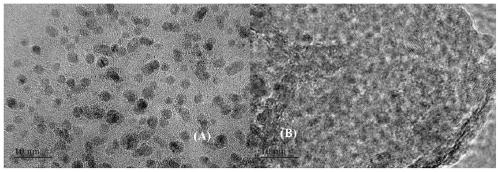

[0047] 1.TEM

[0048] High-resolution transmission electron microscope JEM-2100F, JEOL (Hitachi, Japan) was used to analyze the particle size and morphology of porous materials loaded with ultrafine nano-zero valent iron.

[0049] figure 2 A is a composite material of ultrafine zero-valent iron / graphitized carbon that can be obtained by heating at high temperature under the protection of organic iron salt and ligand inert gas; figure 2 B is a composite material loaded with ultrafine zero-valent iron prepared by "fumigation method" with activated carbon as the carrier. It can be seen from these figures that the zero-valent iron prepared by the "fumigation method" has a diameter of about 2-6...

Embodiment 3

[0059] Example 3 : Adsorption / catalysis performance test of porous material loaded with ultrafine nanometer zero-valent iron of the present invention

[0060] In this example, methyl orange was selected as a representative, and the adsorption / catalysis performance of the porous material loaded with ultrafine nanometer zero-valent iron was tested.

[0061] The operation steps of the test are as follows: Prepare 80mL of 50mg / L methyl orange standard substance, adjust the pH of the solution to 4.0, put it in a 100mL polyethylene plastic vial, add 8g of coke loaded with ultrafine nano-zero valent iron, and place it in a shaker. Shake, take 1.0mL samples at regular intervals, take the supernatant after centrifugation, and measure the concentration of methyl orange with a UV-Vis spectrophotometer. For the activated carbon powder material loaded with ultra-fine zero-valent iron, configure 200mg / L methyl orange standard 50mL, add 25mg activated carbon powder material loaded with zer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com