Oil and gas field water-based drill cuttings soil conditioner, soil improvement method and improved soil

A technology for drilling cuttings and improver, which is applied in the field of solid waste treatment and resource utilization in oil and gas fields, can solve problems such as lack of mature technology, and achieve the effects of increasing the content of silt particles, being beneficial to soil structure, and reducing the content of sand particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

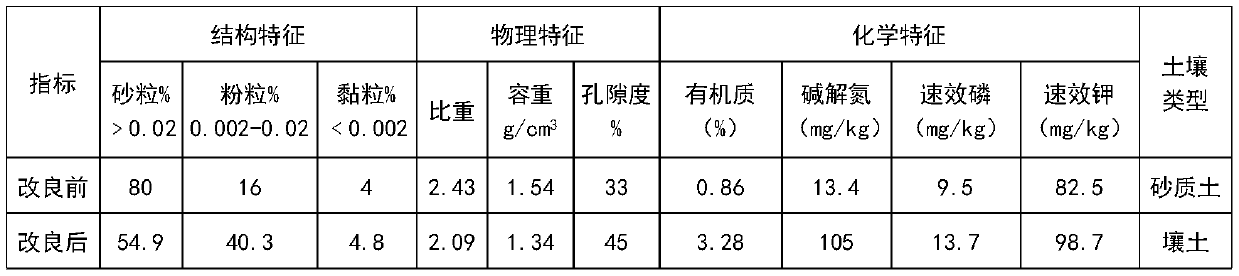

Embodiment 1

[0041] Well X23-78 in an oilfield in the west, the volume of water-based drilling cuttings produced during the drilling process is about 500m after drying treatment 3 , moisture content between 15-20%, density 1.5t / m 3 , and now carry out soil improvement.

[0042] 1. Soil improvement agent: biochar powder, anionic polyacrylamide and fly ash;

[0043] Soil improvement agent formula (by mass percentage): 60% biochar powder + 25% anionic polyacrylamide + 15% fly ash.

[0044] The biochar powder is a solid product produced by low-temperature pyrolysis of crop straws in an anoxic or anaerobic environment, and the particle size of the biochar powder is ≤0.02mm.

[0045] The molecular weight of the anionic polyacrylamide is 15 million.

[0046] The specific surface area of the fly ash is 606m 2 / kg, in terms of volume percentage, the content of particles of 0-5 μm is 32%, the content of particles larger than 50 μm is 9.67%, and the balance is particles of 5-50 μm.

[0047] 2....

Embodiment 2

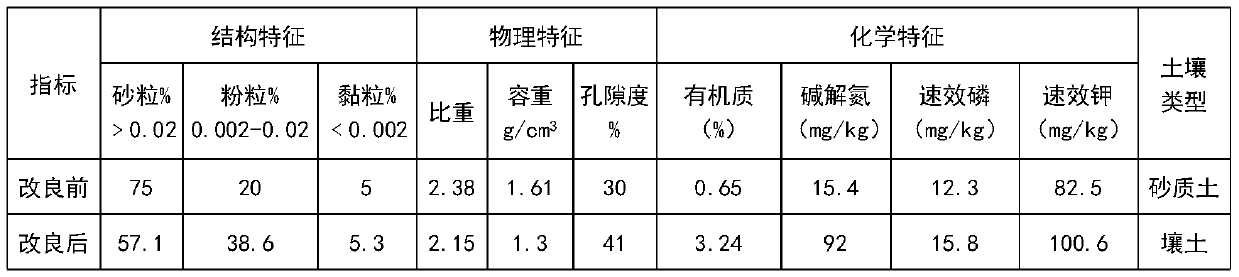

[0052] Well S33-59 in a gas field in the west, the volume of water-based drilling cuttings produced during the drilling process is about 700m after drying treatment 3 , moisture content between 10-15%, density 1.55t / m 3 , and now carry out soil improvement.

[0053] 1. Soil improvement agent: biochar powder, anionic polyacrylamide and fly ash

[0054] Soil improvement agent formula (by mass percentage): 65% biochar powder + 22% anionic polyacrylamide + 13% fly ash.

[0055] The biochar powder is a solid product produced by low-temperature pyrolysis of crop straws in an anoxic or anaerobic environment, and the particle size of the biochar powder is ≤0.02mm.

[0056] The average molecular weight of the polyacrylamide is 18 million.

[0057] The specific surface area of the fly ash is 680m 2 / kg, in terms of volume percentage, the content of particles smaller than 5 μm is 35%, the content of particles larger than 50 μm is 10%, and the particle size of the remaining particle...

Embodiment 3

[0063] In a gas field well in the west, the volume of water-based drilling cuttings produced during the drilling process is about 800m after drying. 3 , moisture content between 15-20%, density 1.55t / m 3 , and now carry out soil improvement.

[0064] 1. Soil improvement agent: biochar powder, anionic polyacrylamide and fly ash

[0065] Soil improvement agent formula (by mass percentage): 63% biochar powder + 20% anionic polyacrylamide + 17% fly ash.

[0066] The biochar powder is a solid product produced by low-temperature pyrolysis of crop straws in an anoxic or anaerobic environment, and the particle size of the biochar powder is ≤0.02mm.

[0067] The average molecular weight of the polyacrylamide is 20 million.

[0068] The specific surface area of the fly ash is 650m 2 / kg, in terms of volume percentage, the content of particles of 0-5 μm is 35%, the content of particles larger than 50 μm is 8.57%, and the balance is particles of 5-50 μm.

[0069] 2. Soil improvemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com