A preparation method of a textile composite material for low-velocity impact protection

A combination of materials, low-speed impact technology, applied in textiles, textiles, papermaking, fabrics, etc., can solve the problem of poor protective performance of protective materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

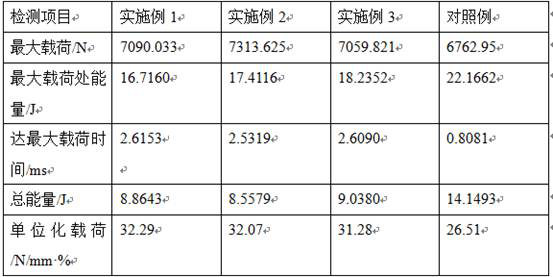

Embodiment 1

[0032] Take polyurethane rubber, basalt rock powder, dispersant BYK-110, and methylene chloride, mix polyurethane rubber and methylene chloride, and perform high-speed stirring to obtain a reaction solution. Add basalt rock powder and dispersant BYK-110 to the reaction liquid, Continue to stir for 1 hour, stand still for defoaming, and then obtain spinning solution A; inject spinning solution A into a syringe for electrospinning, and obtain composite fiber A; mix graphite, epoxy resin and mixed solution, and perform magnetic stirring treatment , to obtain the spinning solution B; inject the spinning solution B into the syringe for electrospinning to obtain the composite fiber B; knead the composite fiber A, composite fiber B and nylon fiber to obtain the matrix fiber, and send the matrix fiber to Put it into the sample weaving machine and weave according to the cardboard pattern to obtain a textile composite material that can protect against low-speed impact. The ratios among ...

Embodiment 2

[0034] Take polyurethane rubber, basalt rock powder, dispersant BYK-110, and methylene chloride, mix polyurethane rubber and methylene chloride, and perform high-speed stirring to obtain a reaction solution. Add basalt rock powder and dispersant BYK-110 to the reaction liquid, Continue to stir for 1 hour, stand still for defoaming, and then obtain spinning solution A; inject spinning solution A into a syringe for electrospinning, and obtain composite fiber A; mix graphite, epoxy resin and mixed solution, and perform magnetic stirring treatment , to obtain the spinning solution B; inject the spinning solution B into the syringe for electrospinning to obtain the composite fiber B; knead the composite fiber A, composite fiber B and nylon fiber to obtain the matrix fiber, and send the matrix fiber to Put it into the sample weaving machine and weave according to the cardboard pattern to obtain a textile composite material that can protect against low-speed impact. The ratios among ...

Embodiment 3

[0036] Take polyurethane rubber, basalt rock powder, dispersant BYK-110, and methylene chloride, mix polyurethane rubber and methylene chloride, and perform high-speed stirring to obtain a reaction solution. Add basalt rock powder and dispersant BYK-110 to the reaction liquid, Continue to stir for 2 hours, stand still for defoaming, and then obtain spinning solution A; inject spinning solution A into a syringe for electrospinning, and obtain composite fiber A; mix graphite, epoxy resin and mixed solution, and perform magnetic stirring treatment , to obtain the spinning solution B; inject the spinning solution B into the syringe for electrospinning to obtain the composite fiber B; knead the composite fiber A, composite fiber B and nylon fiber to obtain the matrix fiber, and send the matrix fiber to Put it into the sample weaving machine and weave according to the cardboard pattern to obtain a textile composite material that can protect against low-speed impact. The ratios among...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com