Silicon-carbon negative electrode material and preparation method and application thereof

A negative electrode material, silicon carbon technology, applied in the field of silicon carbon negative electrode materials and its preparation, can solve the problems of uneven distribution of silicon, affecting the stability of the combination of nano silicon and graphene sheets, agglomeration, etc., and achieve the reduction and suppression of industrial production The effect of expansion and good charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

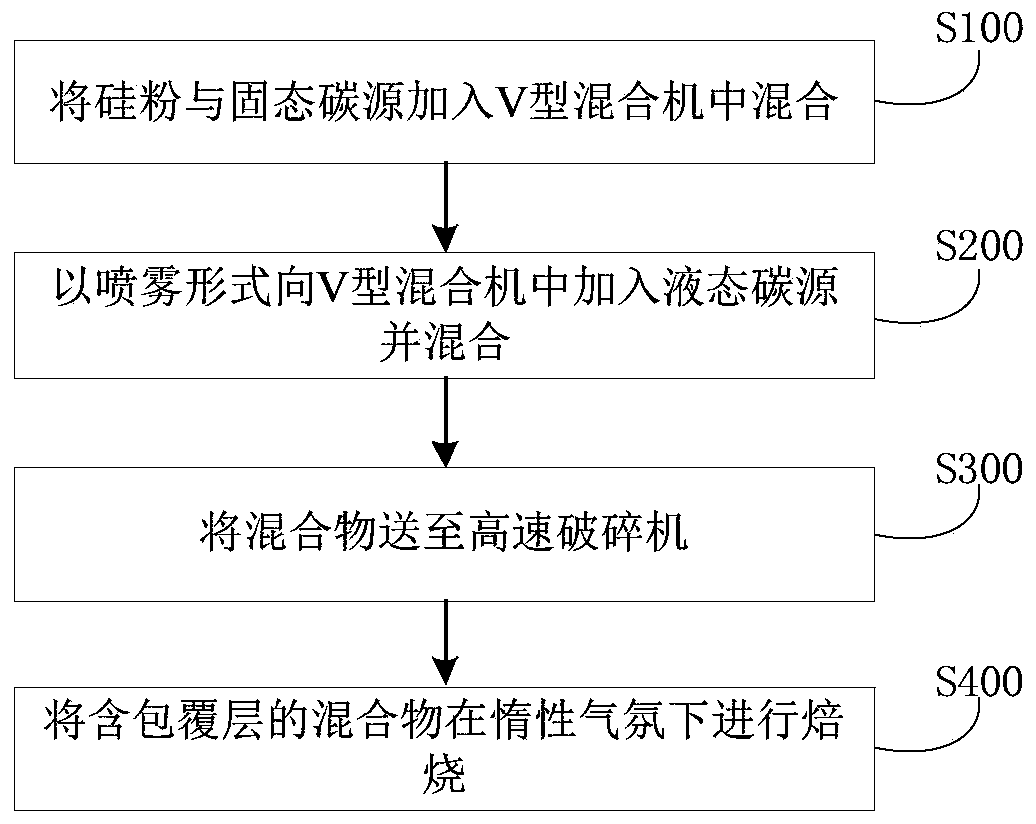

[0055] According to the method for preparing a silicon-carbon negative electrode material according to an embodiment of the present invention, by adding silicon powder and solid carbon source to a V-shaped mixer and mixing, it is beneficial to uniformly disperse the silicon powder and solid carbon source; further, by spraying Add liquid carbon source to the V-type mixer and mix it with evenly mixed silicon powder and solid carbon source, which is conducive to uniform dispersion of liquid carbon source, silicon powder and solid carbon source, and add liquid carbon source in the form of spray It can avoid the agglomeration of particles in the mixture, and is also conducive to improving the dispersion of the liquid carbon source in the mixture, providing conditions for the subsequent uniform film formation on the surface of silicon powder and solid carbon source; by combining liquid carbon source, silicon powder and solid carbon source The mixture is sent to the high-speed crusher...

Embodiment 1

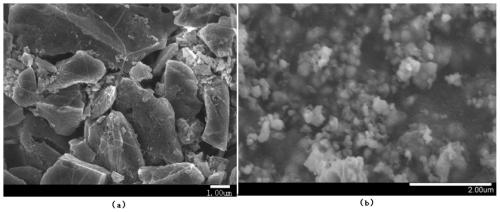

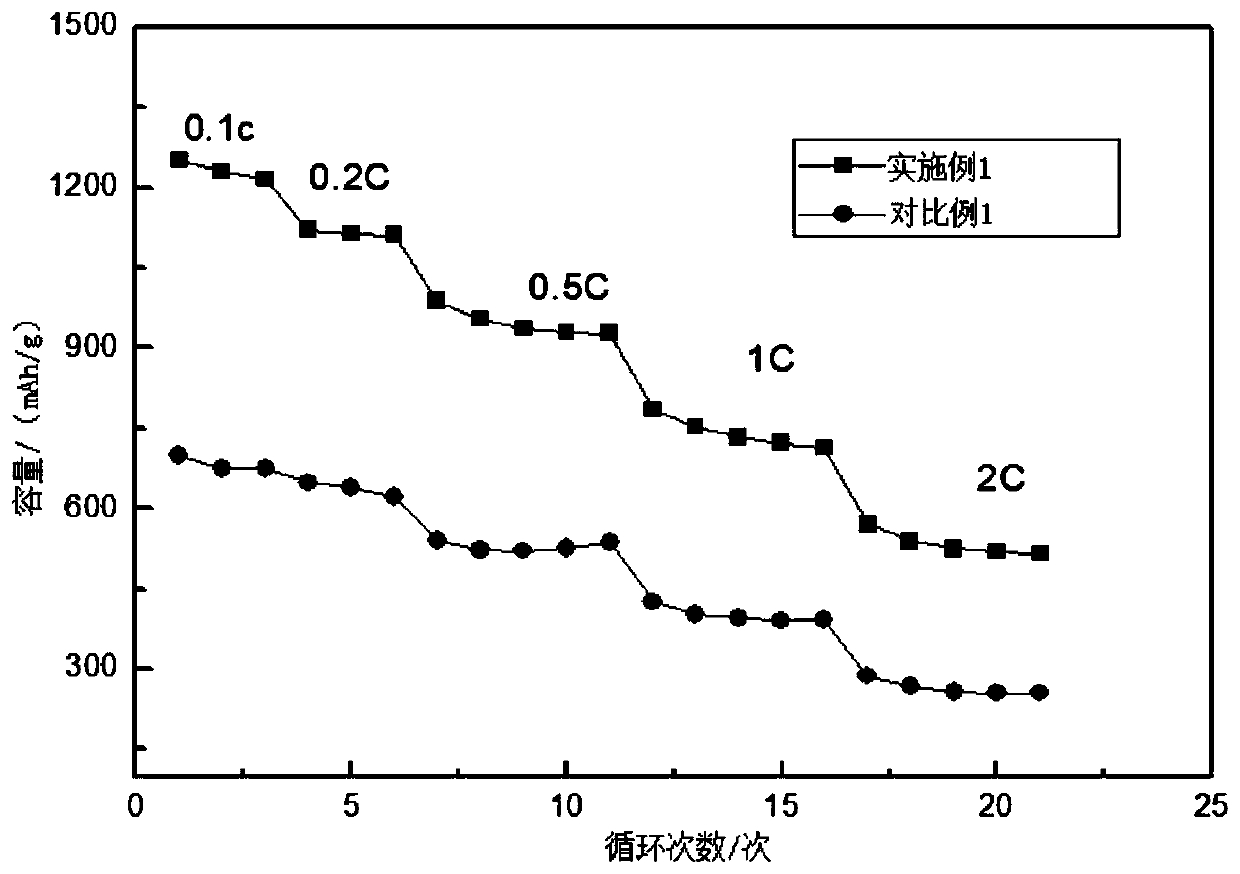

[0062] Take 1.5g of silicon powder with a particle size of 150nm, 5g of graphene with a maximum size of 5μm, and 5g of flake graphite with a maximum size of 5μm and add them to a 150-type V-type mixer and mix for 1 hour at a speed of 10r / min, and then spray 5g of Glucose solution (containing 0.5g glucose) is added in the V-shaped mixer in the form of spraying, and continues to mix for 2 hours at a speed of 10r / min, and the resulting mixture is added to the high-speed crusher at a speed of 300mg / min, and the internal pressure of the high-speed crusher Glucose is coated on the surface of the mixture of silicon powder, graphene and flake graphite by wire drawing to form a film, and the mixture containing the coating layer is roasted in a nitrogen atmosphere, specifically, at a heating rate of 5°C / min The temperature was raised to 600° C. and kept at this temperature for 120 minutes to obtain a stable silicon-carbon negative electrode material. Its scanning electron microscope pic...

Embodiment 2

[0065] Take 0.5g of silicon powder with a particle size of 80nm, 5g of graphite with a maximum size of 12μm, and 5g of expanded graphite with a maximum size of 12μm and add them to a 150-type V-type mixer and mix at a speed of 12r / min for 2.5h, and then spray 4g of Starch solution (containing 1.2g starch) is added in the V-shaped mixer in the form of spraying, and continues mixing for 1 hour at a speed of 12r / min, and the resulting mixture is added to a high-speed crusher at a speed of 600mg / min, and the internal pressure of the high-speed crusher 0.4mPa, the starch is drawn into a film and coated on the surface of the mixture of silicon powder, graphene and graphite flakes, and the mixture containing the coating layer is roasted in a nitrogen atmosphere, specifically, at a heating rate of 2°C / min The temperature was raised to 800° C. and kept at this temperature for 80 minutes to obtain a stable silicon-carbon negative electrode material.

[0066] The silicon carbon negative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com