Method for preparing hexamethylenediamine

A technology of hexamethylenediamine and adipaldehyde, which is applied in reductive alkylation preparation, chemical instruments and methods, molecular sieve catalysts, etc., can solve the problems of dependence on imports, high toxicity of adiponitrile, high price, etc., and achieves a clean route, The effect of improving selectivity and catalyst stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] The preparation of embodiment 1 metal@molecular sieve catalyst

[0081] (1) 2.48gNi(NO 3 ) 2 ·6H 2 O was dissolved in water, and the volume was adjusted to 12mL, and 10g of HBeta molecular sieves (SiO 2 / Al 2 o 3 Molar ratio = 800, SiO 2 The mass content is 98.9%), the Ni element is loaded on the HBeta by the equal volume impregnation method, placed in a 100 ° C oven for 12 hours, and then placed in the HBeta 2 Reduction at 500°C for 4 hours in the atmosphere to obtain metal-loaded Ni / HBeta molecular sieves;

[0082] (2) Place metal-loaded Ni / HBeta molecular sieves in 15 mL of TPAOH aqueous solution with a mass fraction of 35.0%, immerse at room temperature for 2 h, and dry in an oven at 100° C. for 12 h to obtain TPAOH / HBeta molecular sieves adsorbed in the pores;

[0083] (3) Mix the / HBeta molecular sieve with TPAOH adsorbed in the channel with 0.60g sodium hydroxide and 20mL deionized water, and crystallize at 90°C for 6 hours to obtain Ni@ZSM-5 molecular sie...

Embodiment 2-10

[0086] Embodiment 2-10 Preparation of transition metal@molecular sieve catalyst

[0087] The same steps in Example 1 were used to prepare M@ZSM-5, and the metal type and loading amount were adjusted by changing the type and concentration of the metal salt solution. The specific synthesis conditions are listed in Table 1.

[0088] The specific synthetic conditions of each embodiment of table 1

[0089]

[0090] In the table, in the catalyst nA@ZSM-5, A represents the transition metal, ZSM-5 is the abbreviation of HZSM-5, n represents the transition metal mass loading in M / Hbeta, W(%) represents the metal content in M@ZSM-5 mass content.

[0091] Embodiment 1-10 Characterization of metal@molecular sieve catalyst

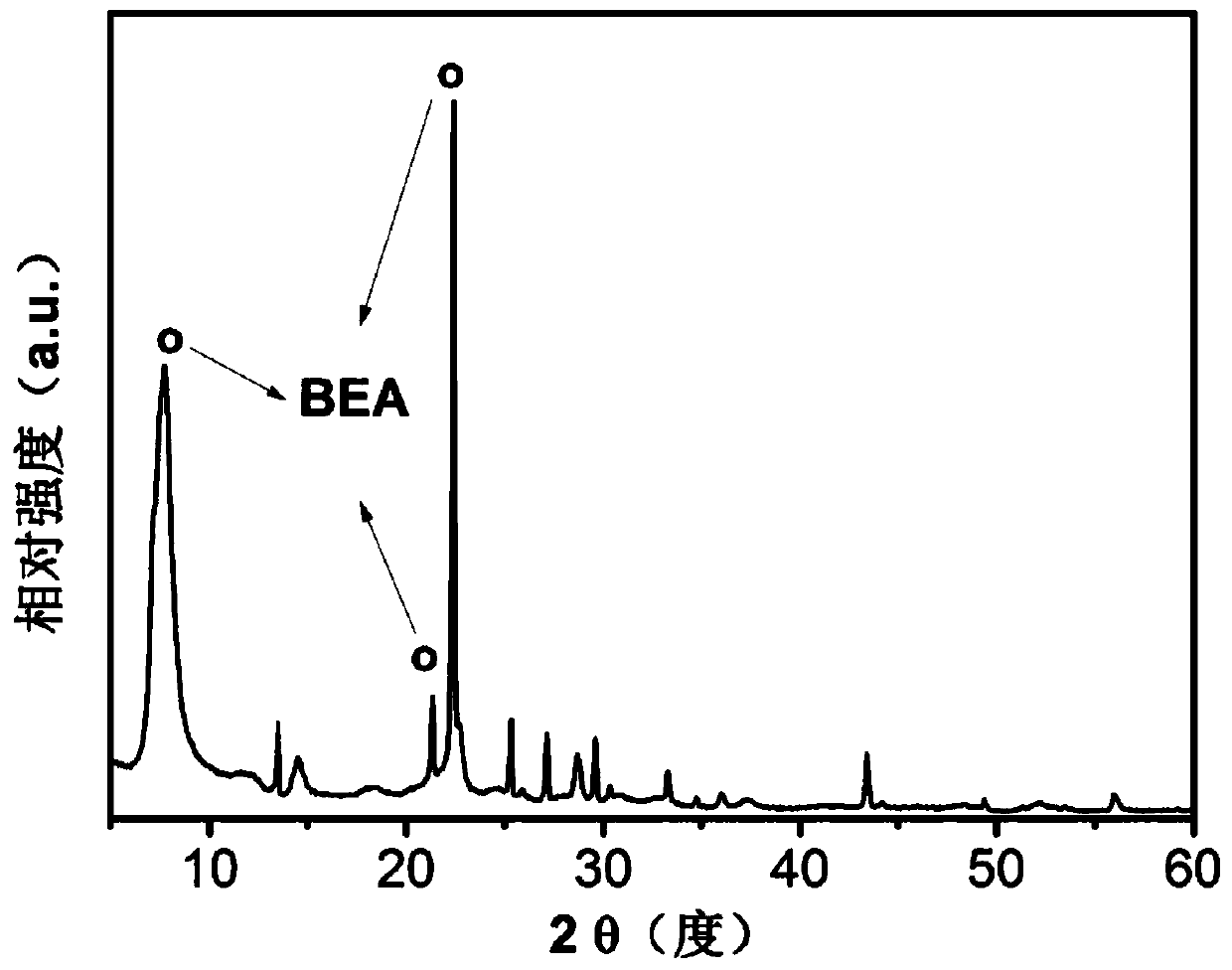

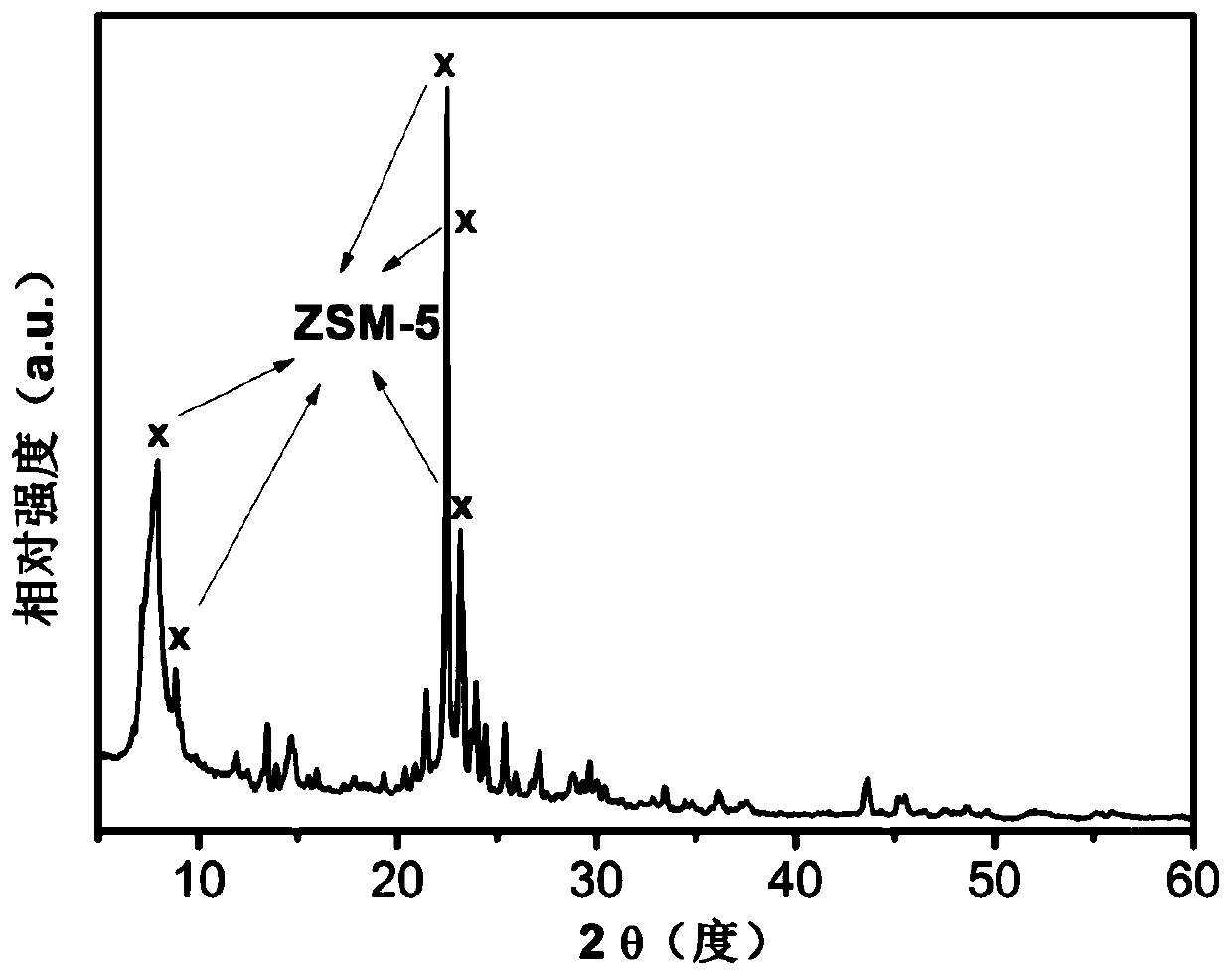

[0092] figure 1 It is the XRD spectrogram of the HBeta molecular sieve used in Example 1; the catalyst obtained in Examples 1 to 10 is a ZSM-5 molecular sieve, and a typical representative is as figure 2 The XRD spectrogram of embodiment 1 catalyst in. The XRD...

Embodiment 11-20

[0093] Reaction Performance Evaluation of Embodiment 11-20 Metal @ Molecular Sieve Catalyst

[0094] Pack 2.0g of the above-mentioned catalyst in a stainless steel fixed-bed reactor with an inner diameter of 10mm and a length of 300mm. Both ends of the catalyst are filled with quartz sand. First, a reducing gas is introduced at a flow rate of 30mL / min, and the catalyst is reduced at 400°C for 4 hours. , wherein the reducing gas composition is H 2 / N 2 The volume ratio is 1 / 4.

[0095] After the reduction, the temperature of the reactor dropped to 130°C, the reaction pressure rose to 6.0Mpa, and H 2 , liquid ammonia and adipaldehyde for reductive amination reaction, wherein liquid ammonia and adipaldehyde are respectively injected into the reaction system through a high-pressure micro feed pump, and the mass space velocity of adipaldehyde is 1.0h -1 , H 2 :NH 3 : adipaldehyde=15:30:1, reaction 10h sampling adopts gas chromatography analysis, and reaction result is listed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com