A kind of production technology of high-quality sodium fatty acid methyl ester sulfonate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Production process of 1t / h sodium fatty acid methyl ester sulfonate

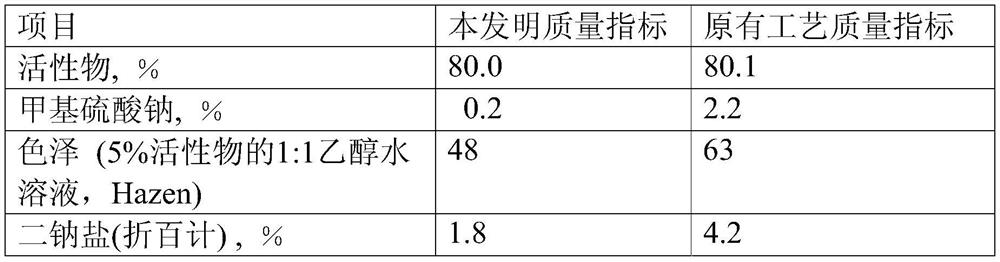

[0027] Fatty acid methyl ester and 7% concentrated SO 3 Enter the membrane reactor at a flow rate of 780kg / h and 275kg / h respectively for sulfonation reaction, control the sulfonation temperature at about 83°C; Add dodecanoic acid for mixing; the mixed sulfonated compound and fatty acid methyl ester flow at 1020kg / h and 153kg / h, respectively, enter the microwave reactor for aging treatment. The microwave temperature is controlled at 88°C, and the microwave aging stays for 16 minutes to obtain the MES intermediate body; methanol at 0.38m 3 The flow rate per hour enters the re-esterification system together with the MES intermediate for re-esterification, bleaching, and neutralization to obtain the MES finished product. The quality indicators of the MES finished product are shown in Table 1:

[0028] Table 1

[0029]

Embodiment 2

[0031] 2.0t / h production process of sodium fatty acid methyl ester sulfonate

[0032] Fatty acid methyl ester and 7% concentrated SO 3 Enter the membrane reactor at a flow rate of 1500kg / h and 560kg / h to undergo a sulfonation reaction, and the sulfonation temperature is maintained at 85°C; after the sulfonation reaction, the sulfonated product separated from the gas-liquid separator is added at a flow rate of 23kg / h Myristic acid is mixed; the mixed sulfonated compound enters the high-speed shear reactor at a flow rate of 2025kg / h and the fatty acid methyl ester at a flow rate of 298kg / h. The temperature is controlled at 85°C, and the high-speed shear reactor stays 24min to obtain the MES intermediate; methanol in 0.75m 3 The flow rate per hour enters the re-esterification system together with the MES intermediate for re-esterification, bleaching, and neutralization to obtain the MES finished product. The quality indicators of the MES finished product are shown in Table 2:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com