Preparation method of vitamin D

A vitamin and solution technology, applied in organic chemistry methods, organic chemistry and other directions, can solve the problems of hidden dangers in production safety, high energy consumption, and high equipment costs, and achieve the effects of improving yield, reducing costs, and high utilization of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

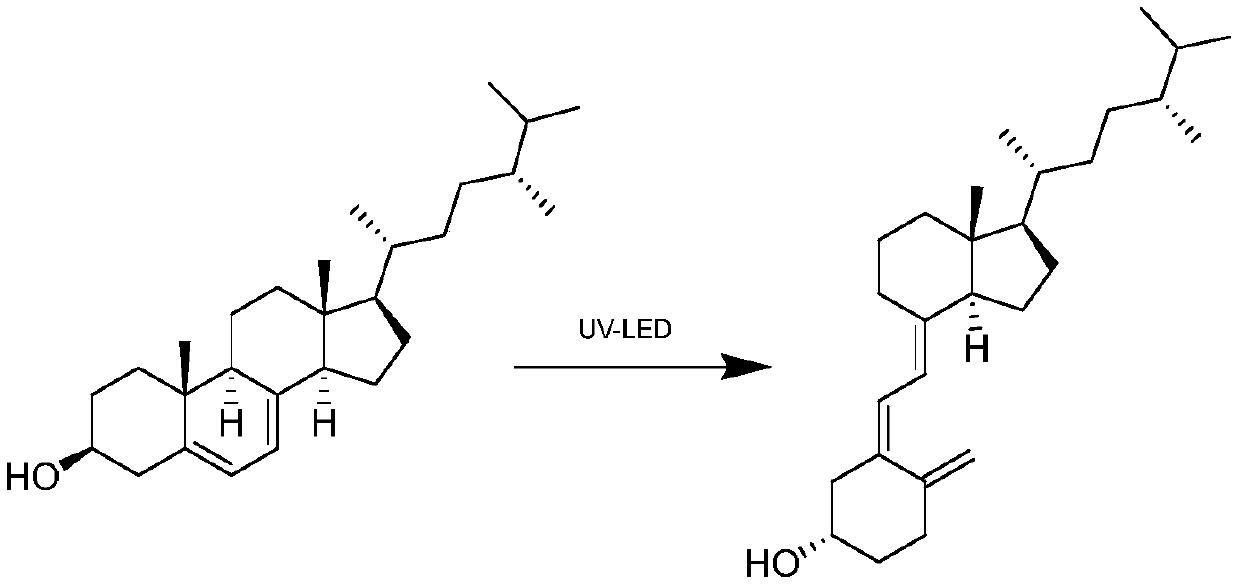

[0042] 1 g of ergosterol and 80 mL of tetrahydrofuran were evenly mixed to obtain solution A. Under the temperature condition of 10-15°C, the solution A was first irradiated with an LED ultraviolet lamp of the model DL-UVC-UV254-30W for 270 minutes, and the solution B was obtained after the irradiation. Under the temperature condition of 10-15°C, the solution B was irradiated with an LED ultraviolet lamp of the model DL-UVA-UV365-40W for 270 minutes, and the solution C was obtained after the irradiation. Distill the solution C under reduced pressure to remove the solvent, add methanol to cool down and stir for crystallization, stir and crystallize at -20°C to -30°C for 24 hours, and recover the filter cake and filtrate by suction filtration. Ergosterol 95% 0.45g, filtrate pre-vitamin D 2 and vitamin D 2mixture. The filtrate was incubated at 65°C for 8h, then at 30-35°C for 48h, concentrated under reduced pressure to dryness to obtain 0.52g (wherein pre-vitamin D 2 8% Vitam...

Embodiment 2

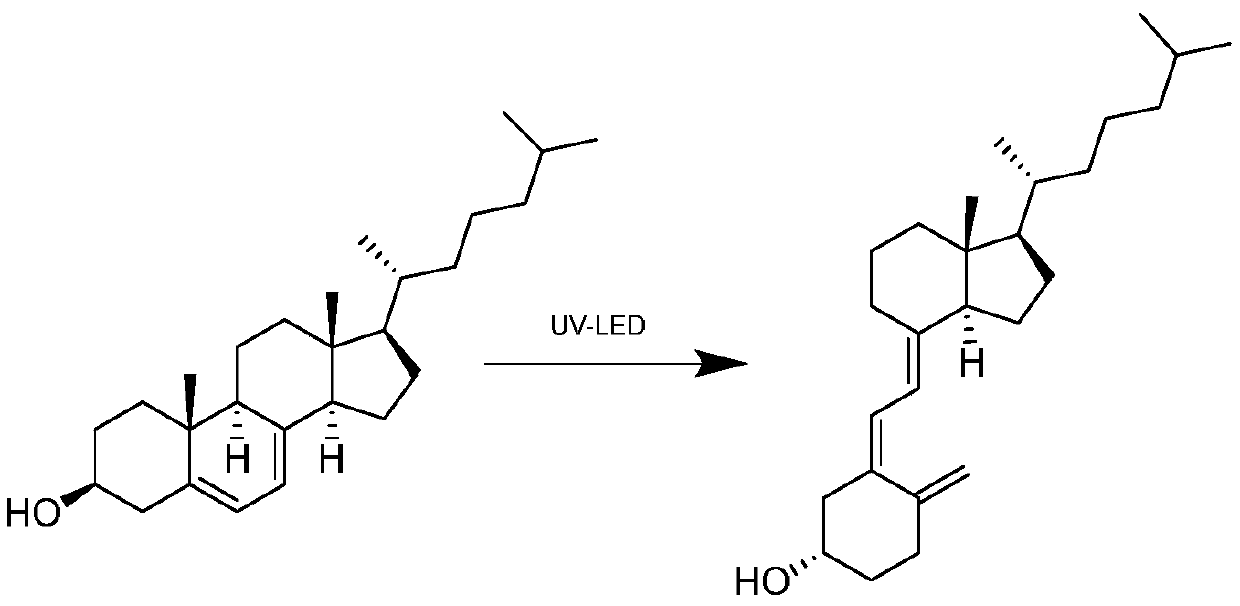

[0044] Mix 1 g of 7-dehydrocholesterol and 100 mL of tetrahydrofuran uniformly to obtain solution A. Under the temperature condition of 10-15°C, the solution A was first irradiated with an LED ultraviolet lamp of the model DL-UVC-UV254-30W for 300 minutes, and the solution B was obtained after the irradiation. Under the temperature condition of 10-15°C, the solution B was irradiated with an LED ultraviolet lamp of the model DL-UVA-UV365-40W for 300 minutes, and solution C was obtained after the irradiation. Distill the solution C under reduced pressure to remove the solvent, add methanol to cool down and stir for crystallization, stir and crystallize at -20°C to -30°C for 24 hours, and recover the filter cake and filtrate by suction filtration. 95% 7-Dehydrocholesterol 0.43g, filtrate pre-vitamin D 3 and vitamin D 3 mixture. The filtrate was incubated at 65°C for 8h, then at 30-35°C for 48h, concentrated under reduced pressure to dryness to obtain 0.54g (wherein pre-vitamin...

Embodiment 3

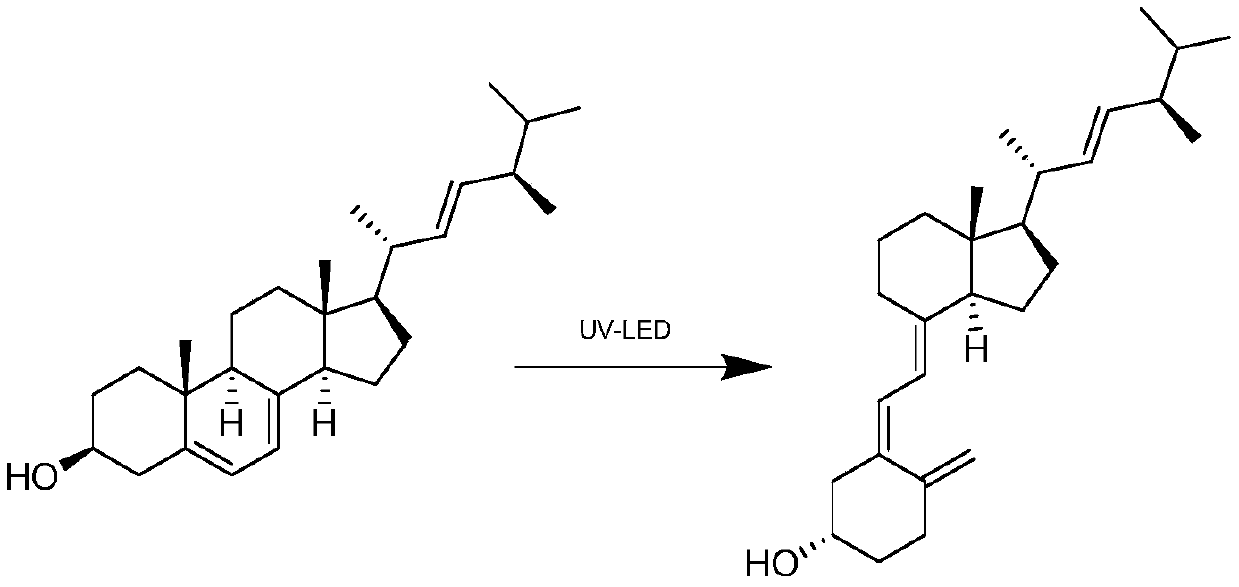

[0046] 1 g of 22,23-dehydroergosterol and 60 mL of tetrahydrofuran were uniformly mixed to obtain solution A. Under the temperature condition of 10-15°C, the solution A was irradiated with the LED ultraviolet lamp of the model DL-UVC-UV254-30W for 240 minutes, and the solution B was obtained after the irradiation. Under the temperature condition of 10-15°C, the solution B was irradiated with an LED ultraviolet lamp of the model DL-UVA-UV365-40W for 240 minutes, and the solution C was obtained after the irradiation. Distill the solution C under reduced pressure to remove the solvent, add methanol to cool down and stir for crystallization, stir and crystallize at -20°C to -30°C for 24 hours, and recover the filter cake and filtrate by suction filtration. 22,23-Dehydroergosterol 95% 0.45g, filtrate pre-vitamin D 4 and vitamin D 4 mixture. The filtrate was incubated at a temperature of 65°C for 8h, then at a temperature of 30-35°C for 48h, and concentrated to dryness under redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com