Phosphorus-containing active ester compound and preparation method thereof

A technology of compound and active ester, which is applied in the field of phosphorus-containing active ester compound and its preparation, can solve the problems of difficult heat resistance and dielectric properties, high glass transition temperature, low dielectric loss value, etc., and achieve good resistance Moist heat effect, reduction of dielectric constant and dielectric loss, effect of small dielectric constant and dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

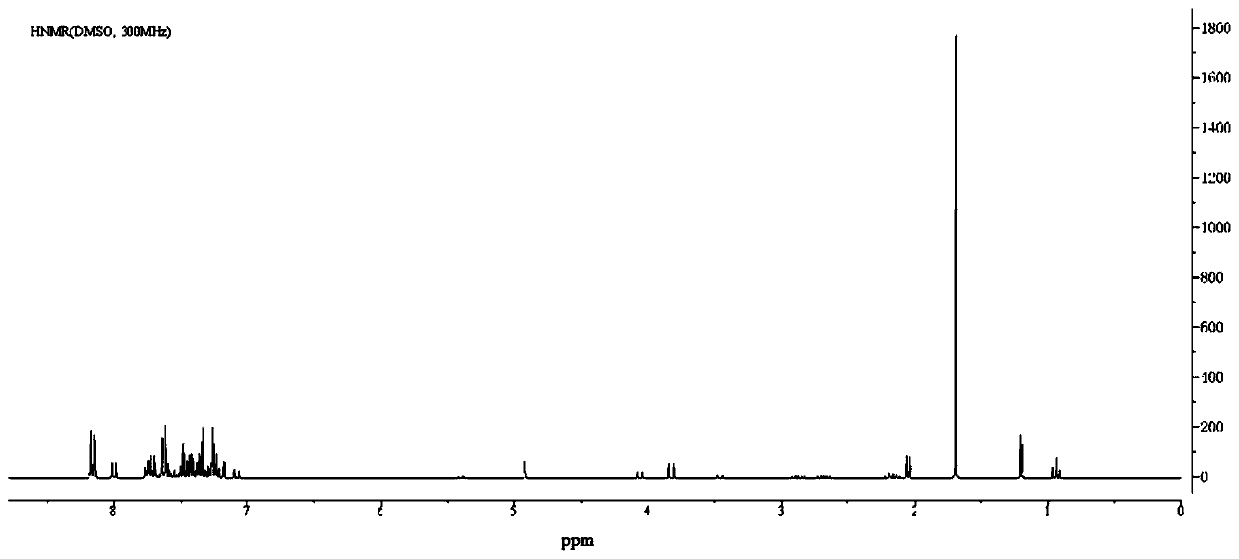

Embodiment 1

[0066]

[0067] (1) Add 0.2 mol of bisphenol A and 0.4 mol of chloroform into 150 mL of 10% aqueous sodium hydroxide solution, and heat to 80° C. for 5 hours to react. Afterwards, the reaction system was neutralized with dilute hydrochloric acid until the pH was approximately equal to 7, extracted with diethyl ether (70 mL×3), and the organic phase was dried by vacuum rotation.

[0068] (2) 0.1mol of the step (1) resultant and 0.1mol of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide were added to 50mL of 50% aqueous sulfuric acid solution , heated to reflux at 100°C for 5 hours. Afterwards, the reaction system was washed with ethanol (50 mL×3) to remove impurities and excess sulfuric acid, and the reaction solution was rotated and dried in vacuum.

[0069] (3) 0.05mol of step (2) gain and 0.1mol of methyl benzoate are dissolved in 30mL of toluene, and 0.02mol of catalyst AlCl is added 3 , heated to reflux at 110° C. for 6 hours, after which the reaction system was was...

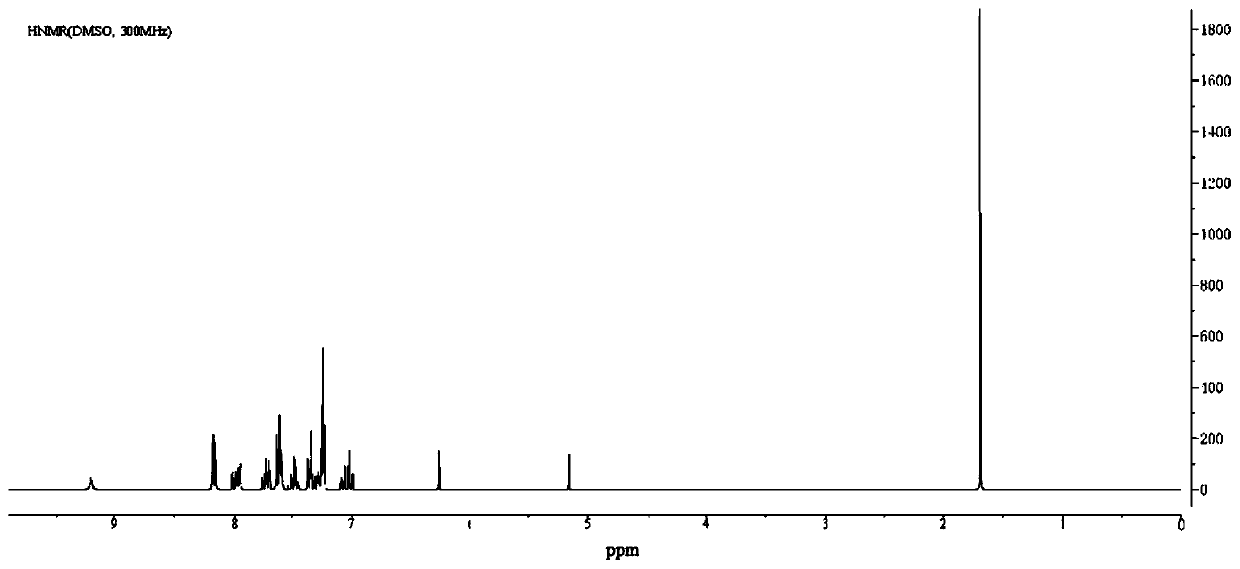

Embodiment 2

[0071]

[0072] Instead of 9,10-dihydro-9-oxa-10- Phosphaphenanthrene-10-oxide, and except that the heating temperature in step (2) was 120° C., the phosphorous-containing active ester compound according to the present invention as shown above was prepared in the same manner as in Example 1.

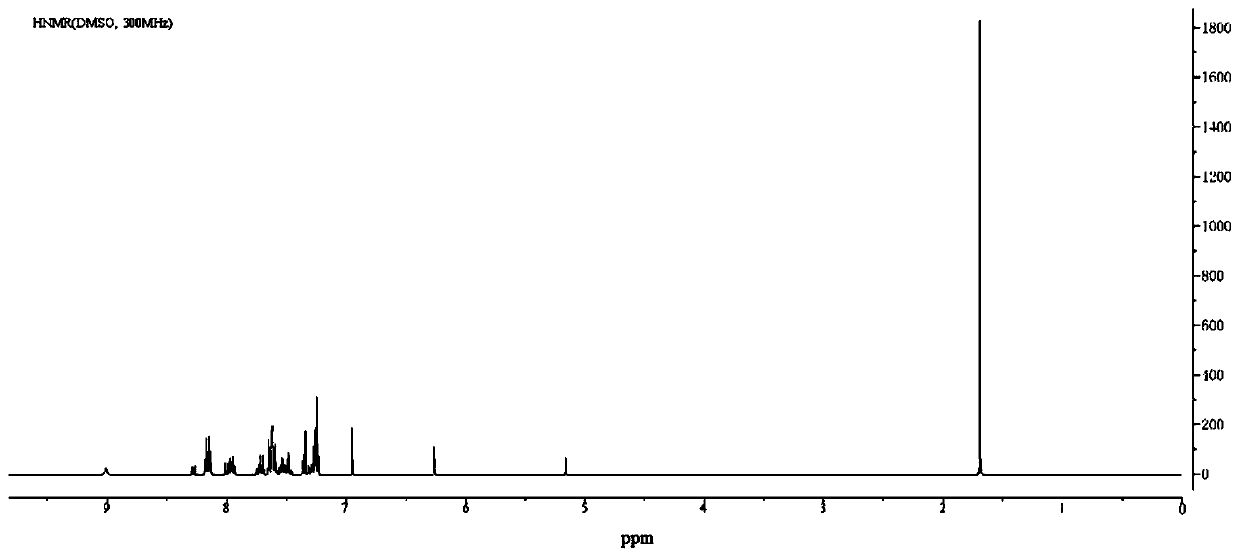

Embodiment 3

[0074]

[0075] Instead of 9,10-dihydro-9-oxa-10- Phosphaphenanthrene-10-oxide, and except that the heating temperature in step (2) was 120° C., the phosphorous-containing active ester compound according to the present invention as shown above was prepared in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com