High-slump-retaining mud-resistant polycarboxylate superplasticizer mother liquor as well as preparation method and application thereof

A technology of anti-mud type and polycarboxylate, which is applied in the field of concrete admixture, can solve the problems of increasing the cost of machinery, labor and materials, increasing the amount of polycarboxylate water reducer, increasing the amount of polycarboxylate water reducer, etc. Achieve the effects of reducing adverse effects, long slump retention time, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

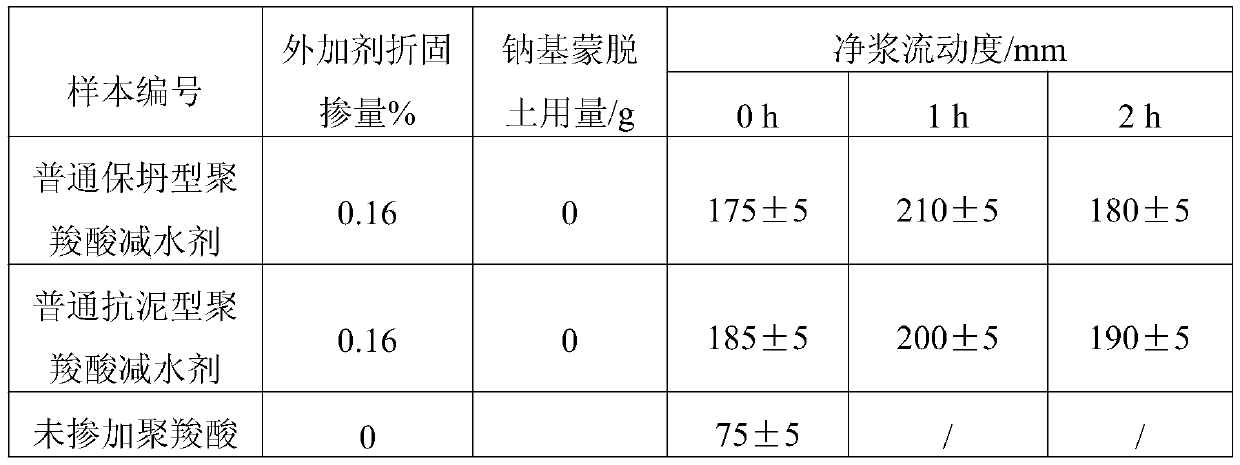

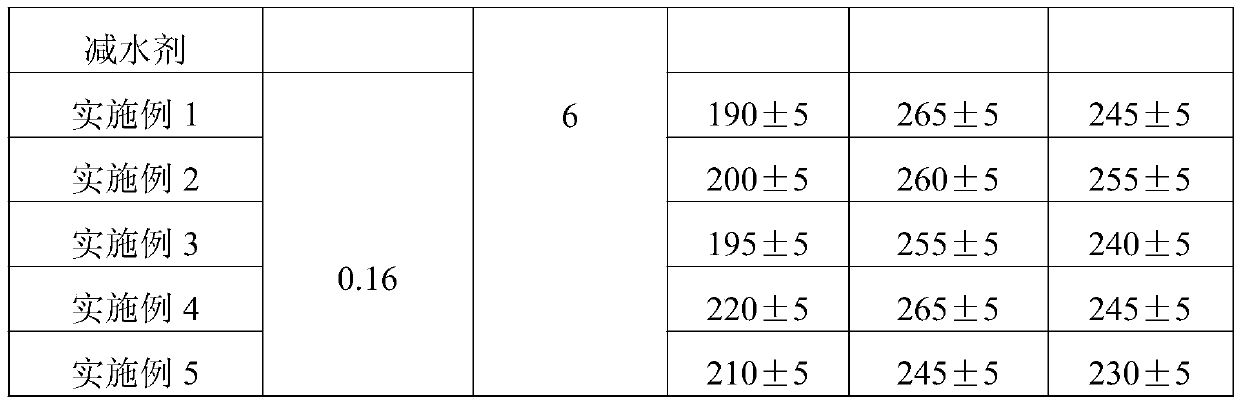

Examples

preparation example Construction

[0031] The preparation method of high slump and anti-mud type polycarboxylate superplasticizer mother liquor specifically comprises the following steps:

[0032] After adding deionized water to the reaction vessel, and controlling the temperature of the reaction vessel within the range of 15-35°C, put in the ether macromonomer and stir until it is completely dissolved;

[0033] Adding unsaturated carboxylic acid and / or anti-mud monomer into the reaction vessel, mixing evenly, and then adding oxidizing agent;

[0034] Dissolve unsaturated carboxylic acid, anti-mud monomer and amide monomer in deionized water to prepare solution A for use; dissolve chain transfer agent and reducing agent in deionized water to obtain solution B. stand-by;

[0035] The solution A and the solution B are added dropwise into the reaction container respectively, the solution A is added dropwise for 1-2.5 hours, and the solution B is added for 1-3 hours;

[0036] After the reaction container is kept ...

Embodiment 1

[0040] Add 330.0g of deionized water to the reactor, and control the temperature of the reactor within the range of 15-35°C by insulating the outer layer of the reactor; then, put 210.0g of methallyl polyoxygen into the reactor Vinyl ether (molecular weight: 2400) and 140.0 g of isopentenol polyoxyethylene ether (molecular weight: 2400), stirring continuously until there is no obvious block or flake material.

[0041] Add 5.0 g of acrylic acid and 8.0 g of dimethyl diallyl ammonium chloride into the reaction kettle, and stir for 5 min; then add 2.5 g of 30% industrial grade hydrogen peroxide, and continue stirring for 10 min.

[0042] Dissolve 17.0 g of acrylic acid, 4.0 g of acrylamide, 3.0 g of N,N-diethyl-2-acrylamide and 2.9 g of 2-acrylamide-2-methylpropanesulfonic acid in 40.0 g of deionized water , that is, the prepared solution A is ready for use.

[0043] Dissolve 1.0 g of mercaptoacetic acid, 1.0 g of mercaptopropionic acid and 0.6 g of ascorbic acid in 100.0 g of d...

Embodiment 2

[0047] Add 330.0g of deionized water to the reactor, and control the temperature of the reactor within the range of 15-35°C through the operation of heating in a water bath; Place in the reaction kettle and keep stirring until the dissolution is complete.

[0048] 9.0g of acrylic acid and 9.0g of DTPMP·Na 7 Add to the above reaction kettle, stir for 10min; add 2.5g of ammonium persulfate, and continue stirring for 10min.

[0049]13.4 g of methacrylic acid, 7.0 g of acrylamide and 1.5 g of 2-acrylamide-2-methylpropanesulfonic acid were dissolved in 40.0 g of deionized water to prepare solution A for use.

[0050] Dissolve 1.0 g of mercaptoacetic acid, 1.0 g of mercaptopropionic acid and 0.6 g of sodium sulfite in 120 g of deionized water to prepare solution B for use.

[0051] The solution A and the solution B were added dropwise into the above-mentioned reaction kettle respectively, the duration of the solution A was 2.5 hours, and the duration of the solution B was 3 hours....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com