Pickering emulsion gel based on mutual attraction of liquid drops and preparation method of Pickering emulsion gel

A technology of mutual attraction and emulsion gel, which is applied in the field of new materials, can solve problems such as the inability to form a three-dimensional cross-linked network and the instability of the oil-gel system, and achieve the effects of strong versatility, strong stability, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

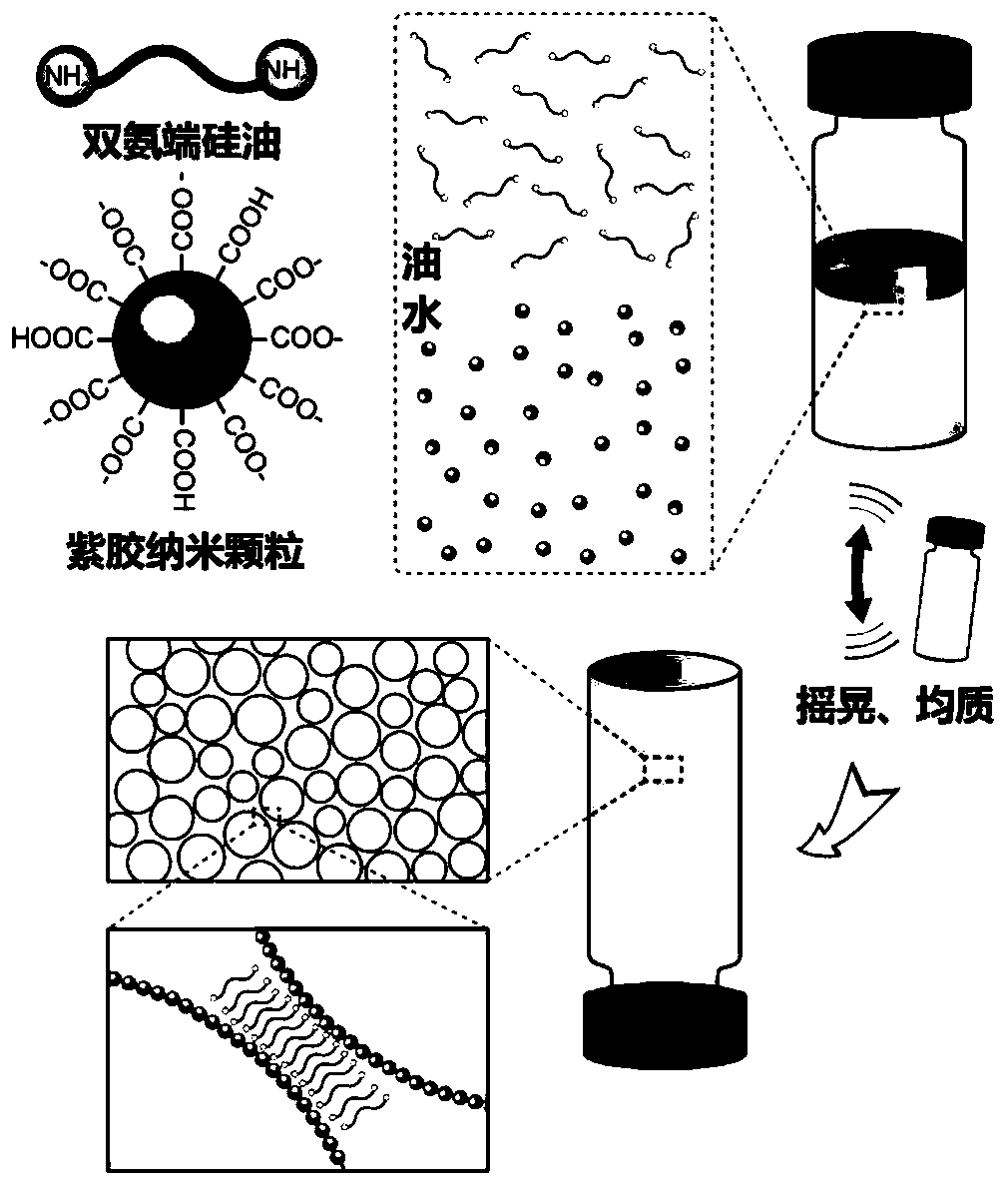

[0061] Example 1: Preparation of Pickering emulsion gel based on mutual attraction of droplets (shellac nanoparticles-diamine-terminated silicone oil / silk oil system) and gel property test

[0062] (1) Disperse shellac nanoparticles in water to prepare a dispersion of shellac nanoparticles with a concentration of 0.8 mg / ml; dissolve diamino-terminal silicone oil in silk oil to prepare 10 mg / ml of diamino-terminal silicone oil / silk oil , then shake well.

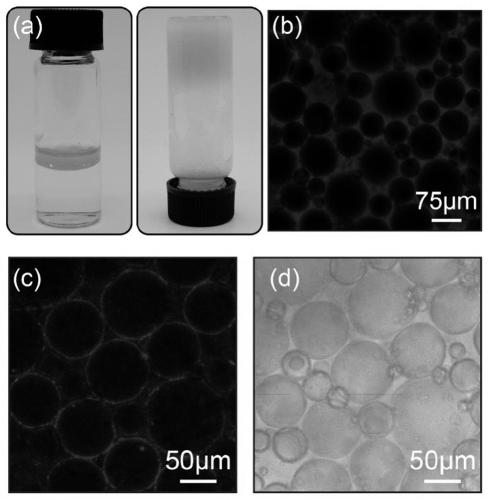

[0063] (2) Draw 1.6ml of the water phase and 0.4ml of the oil phase into the glass bottle, then shake until the mixture turns into a viscous emulsion. After standing for 1 hour, the emulsion forms a gel. Turn the glass bottle upside down, and the emulsion gel will not flow, as attached figure 1 And attached figure 2 (a) shown.

[0064] (3) According to the method in steps (1) and (2), add a small amount of Nile Red to the oil phase to prepare a Pickering gel based on the mutual attraction of droplets, and use a confocal m...

Embodiment 2

[0066] Example 2: Properties of Pickering emulsion gels based on mutual attraction of droplets

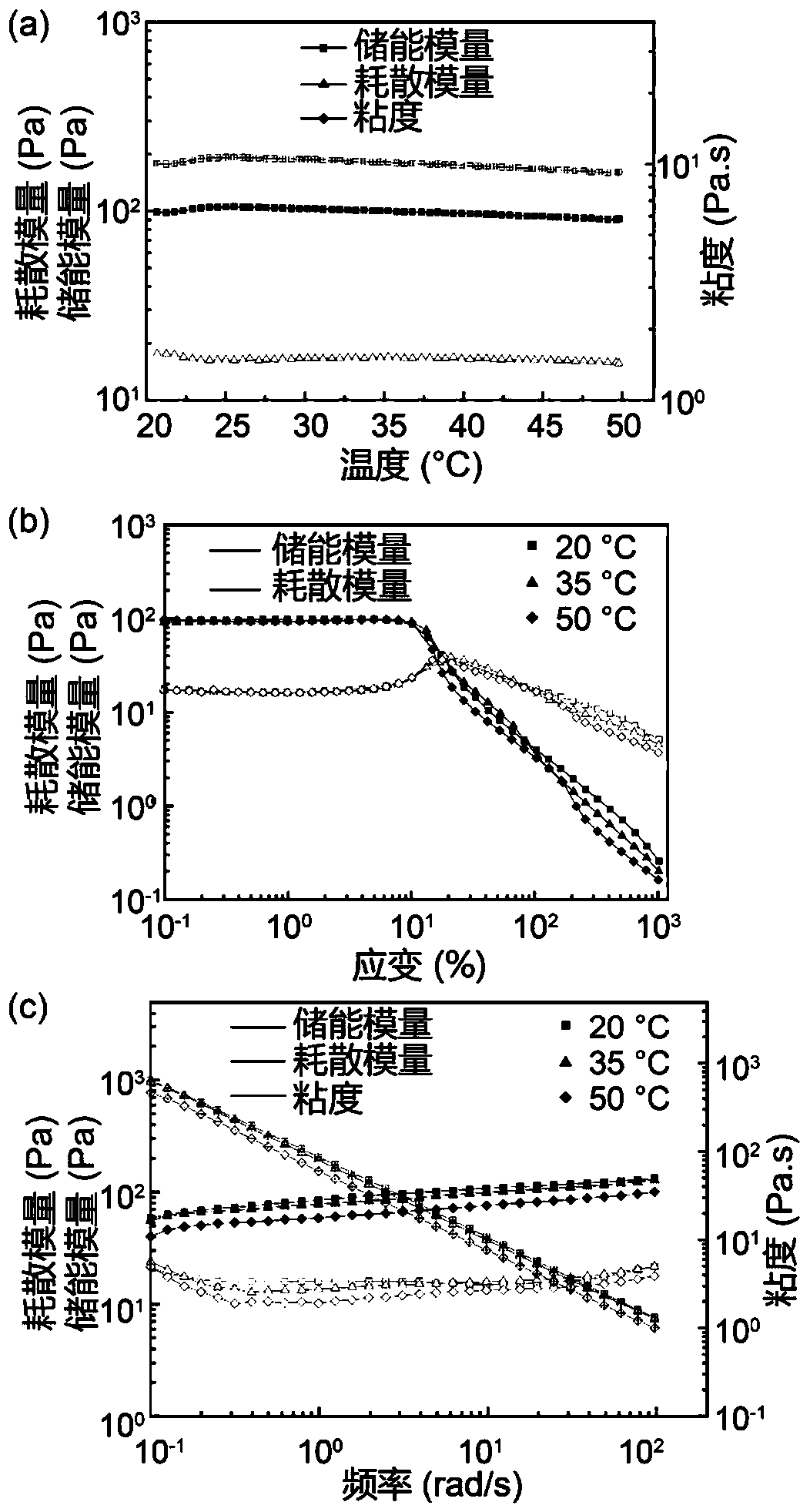

[0067] (1) Rheological properties: According to the method in Example 1, the Pickering emulsion gel based on the mutual attraction of droplets is prepared by using an oil-water ratio of 1:4, and the obtained emulsion gel based on the flat plate system of a rotational rheometer is used to measure rheological properties. The results of the temperature scan are attached image 3 As shown in (a), the storage modulus, dissipation modulus, and viscosity of the gel are basically unchanged with the increase of temperature, indicating that the obtained Pickering based on the mutual attraction of droplets is as good as that of the gel at 20°C-50°C in one day. Good stability. The results of the strain scan are attached image 3 As shown in (b), the storage modulus of the gel decreases exponentially at a strain of 10%, the dissipation modulus rises at 8%, then falls and intersects the stora...

Embodiment 3

[0078] Example 3: Underwater 3D printing of gel

[0079] (1) According to the method in Example 1, the Pickering emulsion gel based on the mutual attraction of droplets was prepared using an oil-water ratio of 1:4.

[0080] (2) Pour the gel into the syringe, push the syringe through the syringe pump to extrude the gel, then use a plastic tube to connect the syringe and the needle of the 3D printer, and extend the needle of the 3D printer into a container filled with water in, as attached Figure 10 (a) shown.

[0081] (3) Design the model through software modeling and slice it to obtain the printing path.

[0082] (4) Use a syringe pump to control the extrusion speed of the gel, and a 3D printer to control the path of the needle, which can print out the required 2D patterns and 3D models underwater, as shown in the attached Figure 10 (b) and (c) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com