Production method of super-thick latex sofa cushion

A production method and technology of sofa cushions, applied in mattresses, spring mattresses, stuffed cushions, etc., can solve the problems that the materials are easy to breed bacteria, mites, do not have health care functions, and the health of users is unfavorable, so as to relieve pressure, Good antibacterial effect, improve the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

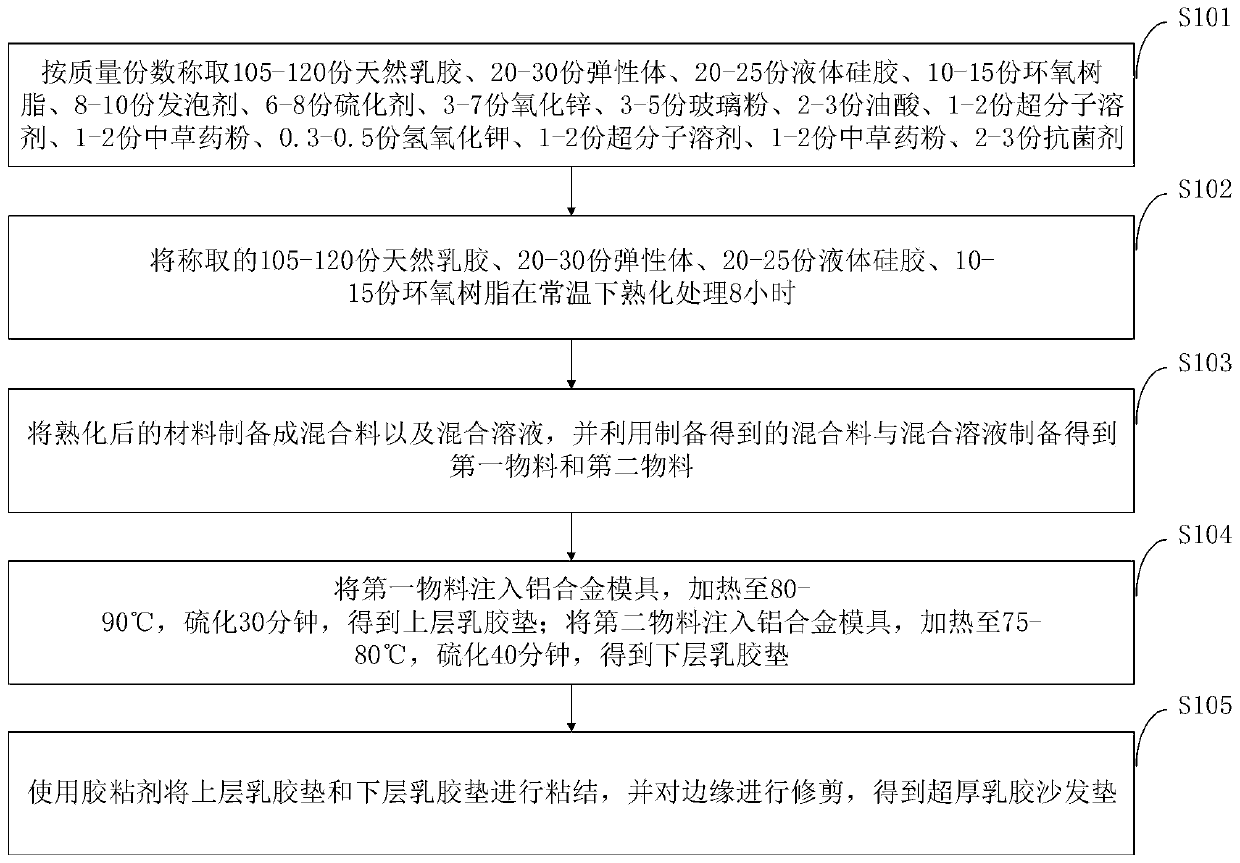

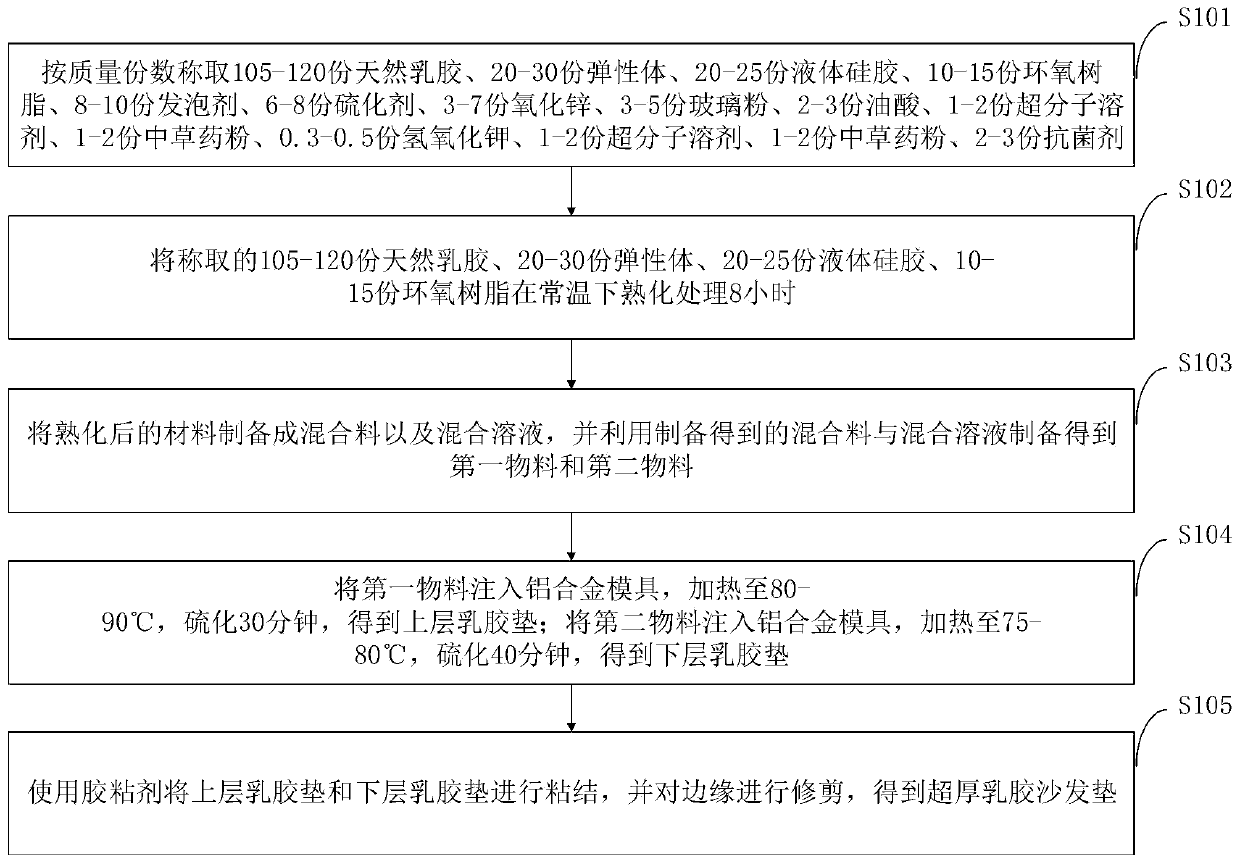

Method used

Image

Examples

preparation example Construction

[0040] In step S101, the preparation method of Chinese herbal medicine powder provided by the embodiment of the present invention includes:

[0041] Firstly, 3-5 parts of chrysanthemum, 5-6 parts of astragalus and 2-3 parts of rhizoma rhizome are weighed according to the parts by mass; they are washed 2-3 times with deionized water and air-dried naturally.

[0042] Secondly, the air-dried chrysanthemum, astragalus and sealwort are pulverized through a 120-mesh sieve to obtain the Chinese herbal medicine powder.

[0043] In step S103, the mixture preparation method provided by the embodiment of the present invention includes:

[0044] Take 35-40 parts of natural latex after aging treatment, 10-15 parts of elastomer, 10-15 parts of liquid silica gel, 5-8 parts of epoxy resin, 1-2 parts of zinc oxide, 0.1-0.2 parts of potassium hydroxide, 1 - 2 parts of supramolecular solvent, 1-2 parts of Chinese herbal medicine powder, 2-3 parts of oleic acid, and 1-2 parts of glass powder are...

Embodiment 1

[0056] Step 1, weigh 105 parts of natural latex, 20 parts of elastomer, 20 parts of liquid silica gel, 10 parts of epoxy resin, 8 parts of foaming agent, 6 parts of vulcanizing agent, 3 parts of zinc oxide, and 3 parts of glass powder by mass parts , 2 parts of oleic acid, 1 part of supramolecular solvent, 1 part of Chinese herbal medicine powder, 0.3 parts of potassium hydroxide, 1 part of supramolecular solvent, 1 part of Chinese herbal medicine powder and 2 parts of antibacterial agent.

[0057] In step 2, 105 parts of natural latex, 20 parts of elastomer, 20 parts of liquid silica gel, and 10 parts of epoxy resin were aged at room temperature for 8 hours.

[0058] Step 3, preparing the cured material into a mixture and a mixed solution, and using the prepared mixture and mixed solution to prepare a first material and a second material.

[0059] Step 4: inject the first material into the aluminum alloy mold, heat to 80°C, and vulcanize for 30 minutes to obtain the upper lat...

Embodiment 2

[0062] Step 1, weigh 110 parts of natural latex, 25 parts of elastomer, 22 parts of liquid silica gel, 13 parts of epoxy resin, 9 parts of foaming agent, 7 parts of vulcanizing agent, 5 parts of zinc oxide, and 4 parts of glass powder by mass parts , 2 parts of oleic acid, 1 part of supramolecular solvent, 1 part of Chinese herbal medicine powder, 0.4 part of potassium hydroxide, 1 part of supramolecular solvent, 1 part of Chinese herbal medicine powder and 2 parts of antibacterial agent.

[0063] In step 2, 110 parts of natural latex, 25 parts of elastomer, 22 parts of liquid silica gel, and 13 parts of epoxy resin were aged at room temperature for 7 hours.

[0064] Step 3, preparing the cured material into a mixture and a mixed solution, and using the prepared mixture and mixed solution to prepare a first material and a second material.

[0065] Step 4: inject the first material into an aluminum alloy mold, heat to 85°C, and vulcanize for 25 minutes to obtain an upper latex ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com