High temperature resistant silane modified adhesive and its preparation method and application

A silane-modified and silane-modified polyether technology, which is applied in the direction of non-macromolecular adhesive additives, adhesives, polyether adhesives, etc., can solve the problem of high temperature resistance of acrylate adhesives that cannot meet the technical requirements of hatch production Insufficient and other problems, to achieve good elasticity, low TVOC, good storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

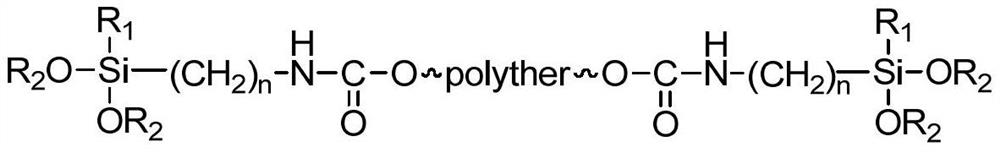

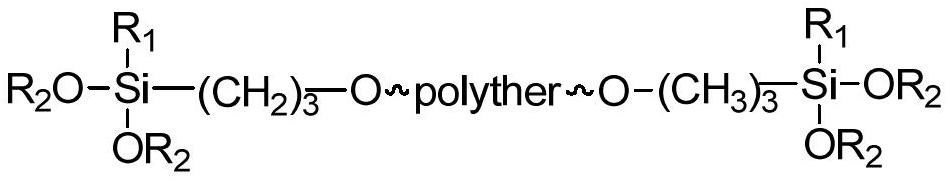

Method used

Image

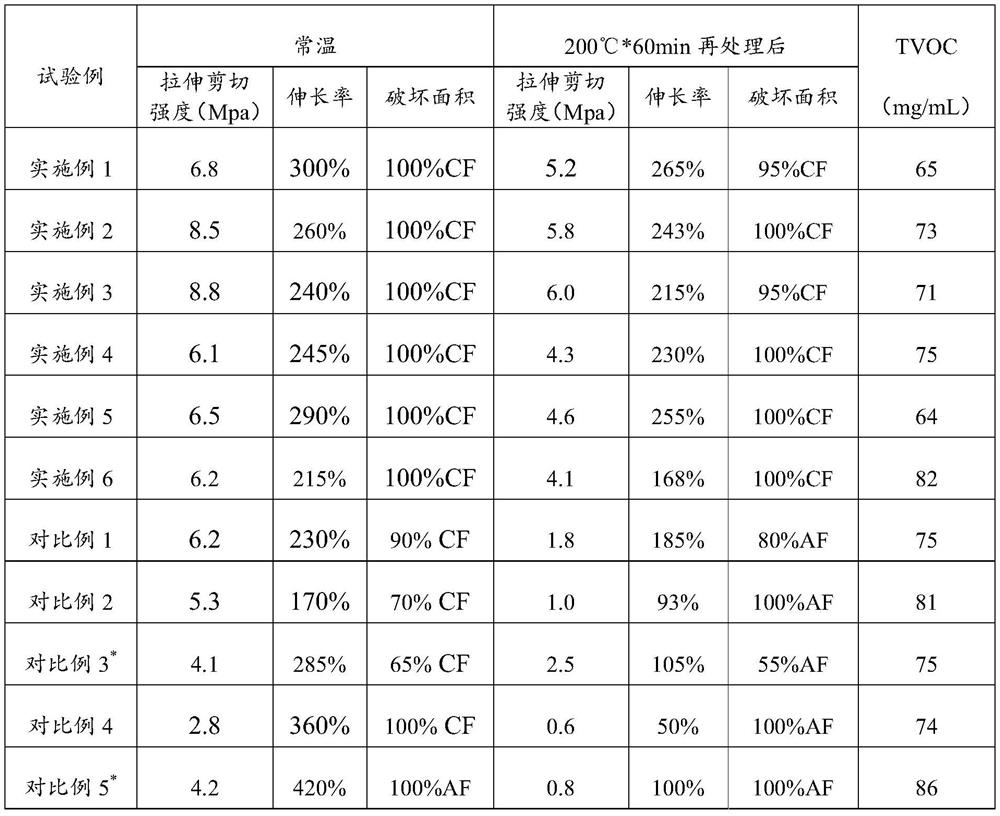

Examples

Embodiment 1

[0053] This embodiment provides a high-temperature-resistant silane-modified adhesive, including component A and component B. Among them, component A: 100 parts of silane modified polymer STP-E 15, 5 parts of diisoamyl phthalate DINP, 15 parts of nano-calcium CCS25, 0.5 parts of UV absorber Tinuvin326, 0.5 parts of light stabilizer Tinuvin770, 0.5 parts of colorant, 2 parts of methyl trimethoxy silane, 3 parts of γ-aminopropyltriethoxysilane and 5 parts of 2,4,6-tris(dimethylaminomethyl)phenol.

[0054]Component B: 100 parts of epoxy resin E-51, 20 parts of polyisobutylene, 10 parts of activated 4A molecular sieve raw powder, 0.5 parts of water and 0.2 parts of dibutyltin dilaurate.

[0055] This embodiment also provides a preparation method of the high-temperature-resistant silane-modified adhesive, which includes the following steps:

[0056] Preparation of component A: Weigh each raw material according to the composition of component A, and the silane-modified polymer ...

Embodiment 2

[0059] This embodiment provides a high-temperature-resistant silane-modified adhesive, including component A and component B. Among them, component A: 100 parts of silane modified polymer SAX260, 8 parts of dioctyl phthalate DOP, 25 parts of heavy calcium carbonate, 0.5 parts of UV absorber Tinuvin327, 0.8 parts of light stabilizer Tinuvin327, 1 Parts of colorant, 4 parts of dimethyldimethoxysilane, 5 parts of N-β-aminoethyl-γ-aminopropyltrimethoxysilane and 6 parts of (1,3-cyclohexanedimethylamine) alicyclic amine.

[0060] Component B: 100 parts of epoxy resin E-44, 25 parts of polybutadiene, 8 parts of activated 5A molecular sieve raw powder, 1 part of water and 0.5 parts of dibutyltin diacetate.

[0061] The preparation method of the high-temperature resistant silane-modified adhesive of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0063] This embodiment provides a high-temperature-resistant silane-modified adhesive, including component A and component B. Among them, A component: 100 parts of silane modified polymer SAX580, 12 parts of polyether polyol (molecular weight 2500), 30 parts of heavy calcium carbonate, 0.5 parts of UV absorber Tinuvin326, 0.5 parts of light stabilizer Tinuvin5050, 2 Parts of colorant, 8 parts of dimethyldimethoxysilane, 2 parts of N-β-aminoethyl-γ-aminopropyltrimethoxysilane, and 3 parts of N,N'-bis(3-aminopropyl) -1,2-Ethylenediamine.

[0064] Component B: 100 parts of epoxy resin E-42, 10 parts of polyisobutylene, 5 parts of activated 13X molecular sieve powder, 2 parts of water and 1.5 parts of stannous octoate.

[0065] The preparation method of the high-temperature resistant silane-modified adhesive of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com