Preparation method of laminated absorption layer of double-gradient band gap CIGS solar cell

A technology for solar cells and absorbing layers, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reduced surface bandgap width, difficulty in controlling quaternary components, and affecting battery efficiency, etc., to achieve improved surface bandgap width, four-dimensional Easy element composition control and good battery uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

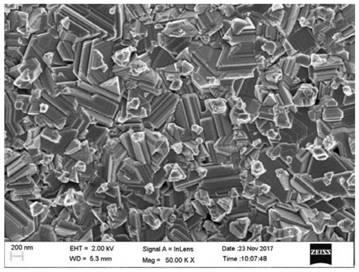

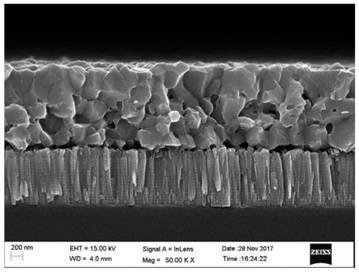

[0028] A method for preparing a laminated absorber layer of a dual gradient bandgap CIGS solar cell, the steps are as follows:

[0029] (1) First sputter 100nm thick SiO on the glass substrate 2 barrier layer.

[0030] (2) on SiO 2 Above the barrier layer, 800nm thick metal Mo is sputtered, and Mo is the bottom electrode of the CIGS thin film battery.

[0031] (3) On the Mo electrode, use the quaternary Cu-In-Ga-Se alloy target to sputter to obtain the bottom layer of the thin film absorption layer, the molar ratio of the target is: Se / (Cu+In+Ga)=1.05; On the bottom layer of the absorbing layer, the surface layer of the thin film absorbing layer is obtained by sputtering with a quaternary Cu-In-Ga-Se alloy target, and the molar ratio of the target is: Se / (Cu+In+Ga)=0.95.

[0032] (4) The molar ratios of the bottom target materials are respectively: Cu / (In+Ga)=0.80, Ga / (In+Ga)=0.30, the chamber is evacuated, when the vacuum degree reaches the background vacuum 2*10 -3 Pa,...

Embodiment 2

[0042] A method for preparing a laminated absorber layer of a dual gradient bandgap CIGS solar cell, the steps are as follows:

[0043] (1) First sputter 100nm thick SiO on the glass substrate 2 barrier layer.

[0044] (2) on SiO 2 Above the barrier layer, 800nm thick metal Mo is sputtered, and Mo is the bottom electrode of the CIGS thin film battery.

[0045] (3) On the Mo electrode, use the quaternary Cu-In-Ga-Se alloy target to sputter to obtain the bottom layer of the thin film absorption layer, the molar ratio of the target is: Se / (Cu+In+Ga)=1.00; On the bottom layer of the absorbing layer, the surface layer of the thin film absorbing layer is obtained by sputtering with a quaternary Cu-In-Ga-Se alloy target, and the molar ratio of the target is: Se / (Cu+In+Ga)=0.90.

[0046] (4) The molar ratios of the bottom target materials are respectively: Cu / (In+Ga)=0.80, Ga / (In+Ga)=0.30, the chamber is evacuated, when the vacuum degree reaches the background vacuum 2*10 -3 Pa,...

Embodiment 3

[0051] A method for preparing a laminated absorber layer of a dual gradient bandgap CIGS solar cell, the steps are as follows:

[0052] (1) First sputter 100nm thick SiO on the glass substrate 2 barrier layer.

[0053] (2) on SiO 2 Above the barrier layer, 800nm thick metal Mo is sputtered, and Mo is the bottom electrode of the CIGS thin film battery.

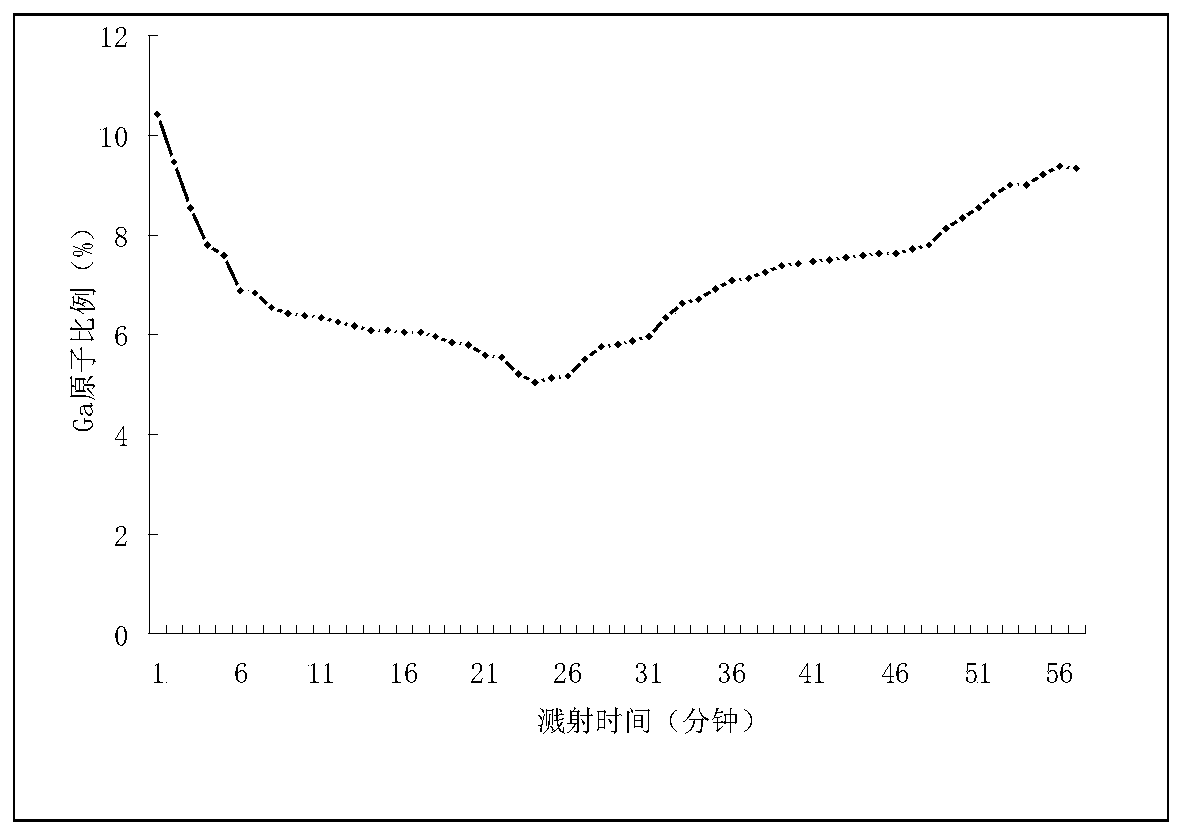

[0054] (3) On the Mo electrode, first sputter the underlying film of the quaternary Cu-In-Ga-Se alloy target, and the molar ratios are: Se / (Cu+In+Ga)=1.09, Cu / (In+Ga )=0.80, Ga / (In+Ga)=0.30; followed by sputtering the quaternary Cu-In-Ga-Se alloy target surface film, the molar ratios are respectively: Se / (Cu+In+Ga)=0.99, Cu / (In+Ga)=0.80, Ga / (In+Ga)=0.30. Two layers of films form an absorbing layer stack, and the sputtering thicknesses of the corresponding bottom film and surface film are both 0.75 μm.

[0055] (4) Vacuum the vacuum annealing furnace before heating, when the vacuum degree reaches the background vacuum 5*1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com