Biological cellulose composite gel material and application thereof as wound dressing

A technology of biological cellulose and composite gel, which is applied in the preparation of wound dressing products. In the field of new biocellulose composite gel materials, it can solve the problems of limiting cell adhesion and proliferation, and the application limitation of biological cellulose. Achieve the effects of promoting adhesion and proliferation, promoting wound healing, and high water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

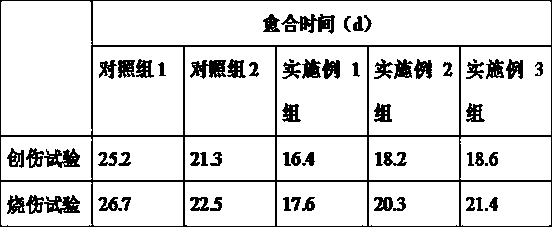

Examples

Embodiment 1

[0024] Embodiment 1: Preparation example 1 of composite gel material

[0025] 1) Preparation of biocellulose hydrogel film by static fermentation method: use coconut water culture medium, gluconoacetobacter xylinum, ferment culture in a shallow plate at 28°C for 7 days, and collect biocellulose hydrogel film on the liquid surface . After cleaning and purification, it is ready for use;

[0026] 2) The biocellulose hydrogel membrane was dehydrated by mechanical pressure to a water content of 60%, then soaked in 0.7wt% globulin solution, ultrasonically oscillated for 6 hours, taken out and washed with water;

[0027] 3) Take 0.05M sodium chloride solution, adjust the pH value to 4 with dilute hydrochloric acid, heat to 80°C, then immerse the biocellulose hydrogel film obtained in step 2) and heat it for 5 hours;

[0028] 4) Take it out and wash it with clean water.

[0029] That is, the composite gel material in the present invention is obtained.

Embodiment 2 : preparation example 2

[0031] 1) Preparation of biocellulose hydrogel film by static fermentation method: using artificially prepared medium, Gluconoacetobacter xylinum, cultured in a shallow plate at 29°C for 9 days, and collecting the biocellulose hydrogel film on the liquid surface . After cleaning and purification, it is ready for use;

[0032] 2) The biocellulose hydrogel membrane was dehydrated to a water content of 40% by mechanical pressure, then soaked in 1wt% ovalbumin solution, ultrasonically oscillated for 8 hours, taken out and washed with water;

[0033] 3) Take 0.2M calcium chloride solution, adjust the pH value to 5 with dilute hydrochloric acid, heat to 70°C, then immerse the biocellulose hydrogel film obtained in step 2), and heat for 4 hours;

[0034] 4) Take it out and wash it with clean water.

Embodiment 3

[0035] Embodiment 3: Preparation example 3 of composite gel material

[0036] 1) Preparation of biocellulose hydrogel by shaking table dynamic fermentation method: use artificially prepared medium, Acetobacter xylinum, and shake table dynamic fermentation culture at 27°C for 5 days, collect biocellulose hydrogel, wash and purify for backup use;

[0037] 2) The collected biocellulose hydrogel was pressed into a film by mechanical pressure, and dehydrated to a water content of 70%, then soaked in a 3wt% soybean protein solution, ultrasonically oscillated for 16 hours, taken out and washed with water;

[0038] 3) Take 0.1M sodium chloride solution, adjust the pH value to 3 with dilute hydrochloric acid, heat to 65°C, then immerse the biocellulose hydrogel film obtained in step 2), and heat for 6 hours;

[0039] 4) Take it out and wash it with clean water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com