Low-pressure high-flux directional moisture-conducting textile-based electroosmotic pump as well as preparation method and application thereof

A directional moisture-wicking, low-pressure and high-pressure technology, which is applied in the field of liquid transmission and smart wearables, can solve the problems of high Joule heat generation, low thermodynamic efficiency, and difficulty in practical application, achieving high Joule heat generation, convenient production, Apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A low-voltage high-flux directional moisture-wicking textile-based electroosmotic pump, including a driving electrode, a track-etched film arranged between the positive driving electrode and the negative driving electrode, and electrically connected to the positive driving electrode and the negative driving electrode respectively. drive power. The driving electrodes include positive driving electrodes and negative driving electrodes; both the positive driving electrodes and the negative driving electrodes are made of a film-like flexible conductive textile fiber material; the track etching film is an electrically insulating microporous film; the driving power is a low-voltage DC power supply. The driving power provides the driving force to realize directional moisture transfer from the positive driving electrode to the negative driving electrode.

Embodiment 2

[0040] Embodiment 2 is an optimization scheme to embodiment 1. In this embodiment, on the basis of Example 1, the base material of the positive electrode drive electrode adopts hydrophilic fiber fabric, the base material of the negative electrode drive electrode adopts hydrophobic fiber fabric, and the track etching film is a track etching polycarbonate microporous film. . This embodiment can further improve the directional moisture transfer efficiency on the basis of the embodiment 1, and avoid the backflow phenomenon.

Embodiment 3

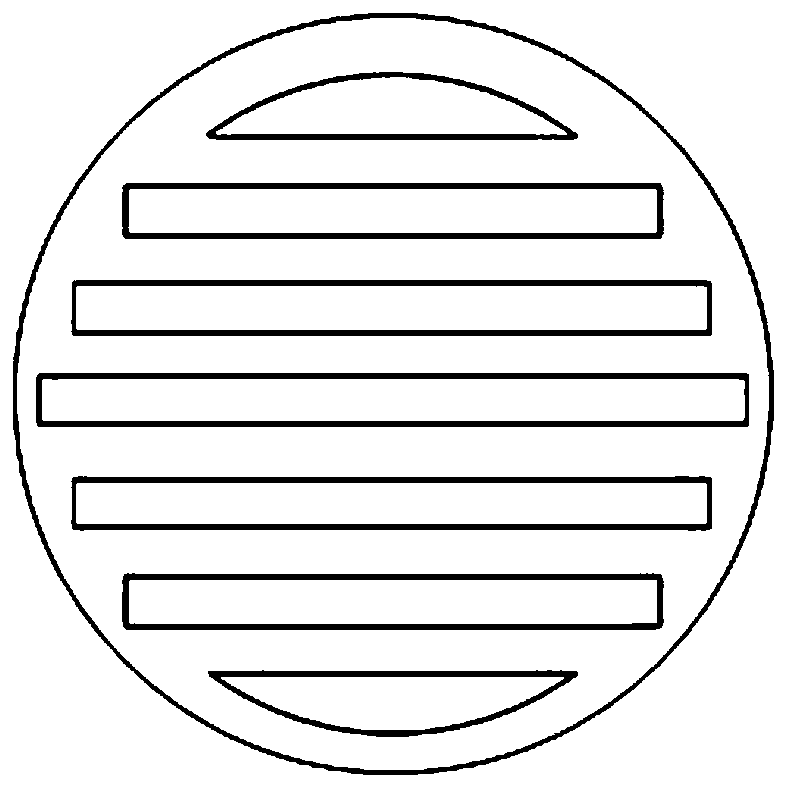

[0042] Embodiment 3 is a further optimization of Embodiment 1 and Embodiment 3, and is also the optimal solution for the selection of positive and negative electrodes. combine figure 1 , in this embodiment, the positive electrode driving electrode is a non-metallic fabric electrode 11; the negative electrode driving electrode is a metal fabric electrode 2. Specifically, the non-metallic fabric electrode 11 adopts one of carbon fiber woven fabrics, graphene woven fabrics, carbon nanotube fabrics, polyaniline fabrics, polypyrrole fabrics, and polythiophene fabrics; A non-woven or woven fabric of one of metals, copper and aluminum. The thickness of the non-metallic fabric electrode 11 is 150 μm-570 μm; the thickness of the metal fabric electrode 2 is 35 μm-550 μm, and the water contact angle is 110°-160°; the thickness of the etched polycarbonate microporous film 3 is 7-20 μm, and the pores The ratio is 4-20%, and the average pore size is 0.4μm-2μm. At the same time, the posit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com