Bamboo desugaring method and preparation method of bamboo filament bundle for anti-corrosion bamboo board

A bamboo and sugar removal technology, applied in wood impregnation, manufacturing tools, wood treatment and other directions, can solve the impact of bamboo mechanical strength, anti-corrosion performance, environmental protection performance, change the mechanical properties and original color of bamboo tow, and affect the quality of bamboo boards, etc. It can improve the anti-corrosion and anti-mildew performance, avoid poor performance and color, and avoid complex ingredients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

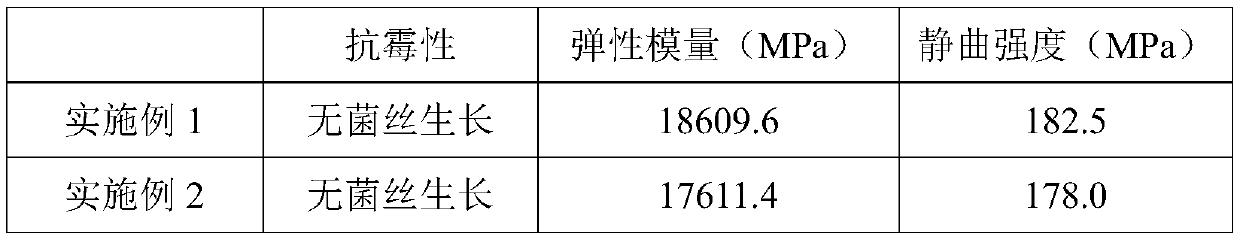

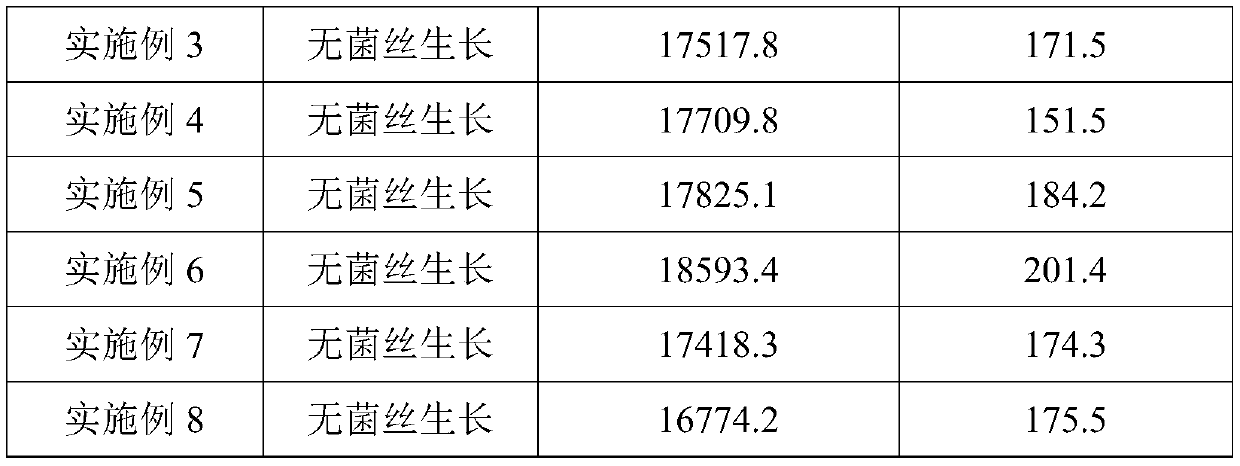

Examples

preparation example Construction

[0051] The second aspect of the present invention provides a method for preparing bamboo filament bundles for antiseptic bamboo boards, comprising the following steps: after the bamboo is desugared by the above-mentioned bamboo desugaring method, after post-treatment, an antiseptic Bamboo boards are made of bamboo strands.

[0052] In one embodiment, the post-treatment includes washing with clean water, drying, and health preservation.

[0053] In a preferred embodiment, the washing liquid after washing with clear water is collected to obtain a sugar-containing deep eutectic solvent aqueous solution, and the sugar-containing deep eutectic solvent aqueous solution is electrodialyzed to obtain a sugar-free deep eutectic solvent aqueous solution , and then evaporate and dehydrate the desugared deep eutectic solvent aqueous solution to obtain a reusable deep eutectic solvent.

[0054] Hereinafter, the present invention is described in more detail through examples, but it should be ...

Embodiment 1

[0057] Embodiment 1 of the present invention provides a kind of bamboo wood desugaring method, comprises the following steps:

[0058] (1) Bamboo pretreatment: After the collected bamboo is cut off, broken and dispelled, it is set aside;

[0059] (2) Add a deep eutectic solvent into a horizontal cooking pot, heat to 90°C, add the bamboo obtained in step (1) after the solvent is completely melted, and perform ultrasonic treatment for 15 hours.

[0060] In step (2), the deep eutectic solvent is a deep eutectic solvent with a molar ratio of phenylacetic acid:choline chloride of 1:1.

[0061] In step (2), the ultrasonic frequency is 22KHz.

[0062] In step (2), the mass ratio of the bamboo material to the deep eutectic solvent is 1:3.5.

[0063] Embodiment 1 of the present invention also provides a kind of preparation method of bamboo tow for antiseptic bamboo board, comprises the following steps: adopt the above-mentioned bamboo material desugaring method to carry out desugarin...

Embodiment 2

[0065] Embodiment 2 of the present invention provides a kind of bamboo wood desugaring method, comprises the following steps:

[0066] (1) Bamboo pretreatment: After the collected bamboo is cut off, broken and dispelled, it is set aside;

[0067] (2) Add a deep eutectic solvent into a horizontal cooking pot, heat to 90°C, add the bamboo obtained in step (1) after the solvent is completely melted, and perform ultrasonic treatment for 15 hours.

[0068] In step (2), the deep eutectic solvent is a deep eutectic solvent with a succinic acid:choline chloride molar ratio of 1:2.

[0069] In step (2), the ultrasonic frequency is 22KHz.

[0070] In step (2), the mass ratio of the bamboo material to the deep eutectic solvent is 1:3.5.

[0071] Embodiment 2 of the present invention also provides a kind of preparation method of bamboo tow for antiseptic bamboo board, comprises the following steps: adopt the above-mentioned bamboo material desugaring method to carry out desugaring treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com