Light high-strength high-toughness multi-cell metal micro-nano structure and preparation method thereof

A micro-nano structure and metal technology, applied in micro-structure technology, micro-structure devices, manufacturing micro-structure devices, etc., can solve the problems of poor strength, application limitations, etc., to reduce production costs, reduce structural quality, and simplify the process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

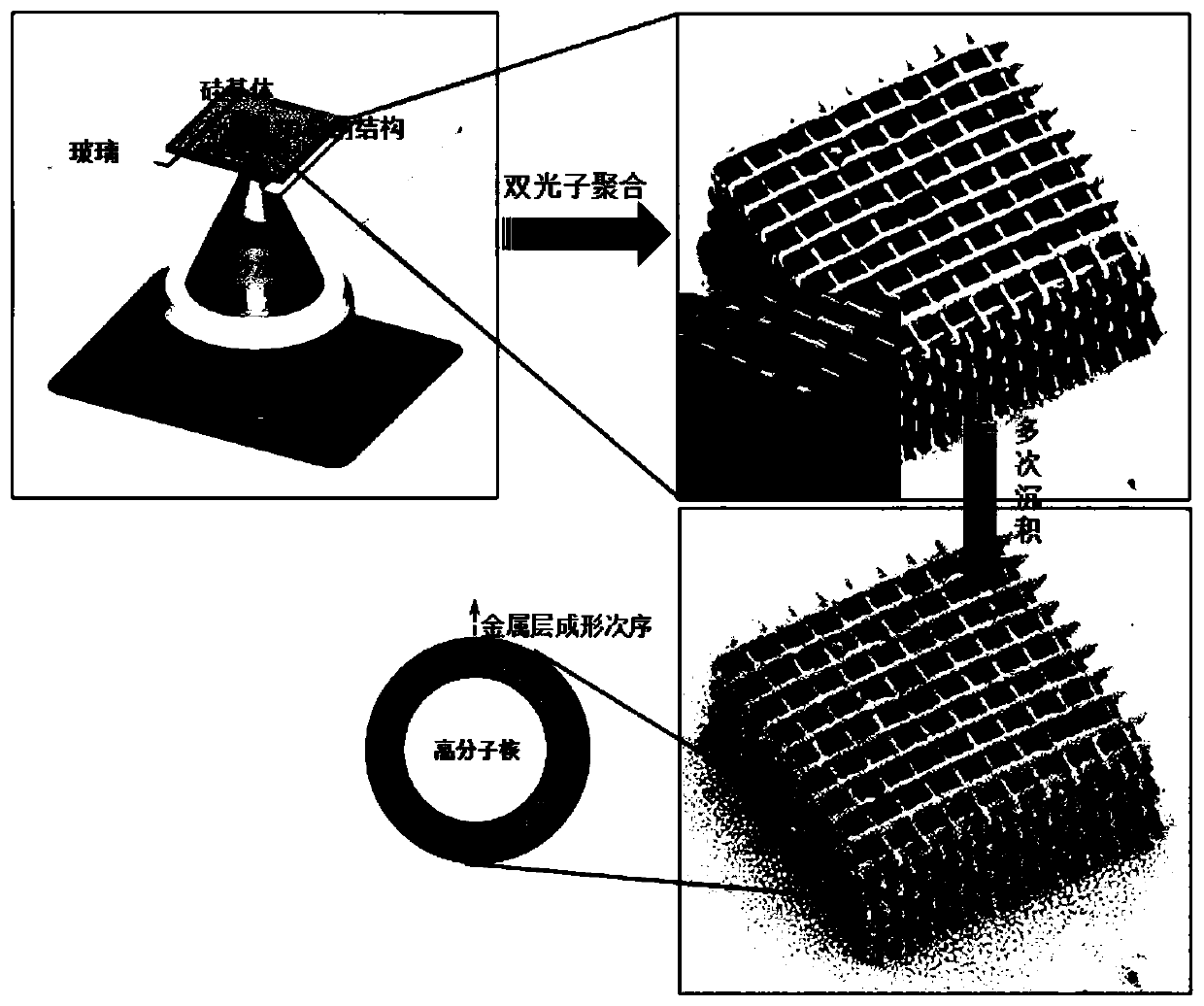

[0023] Such as figure 1 As shown, the preparation method of the light-weight, high-strength and tough multicellular metal micro-nano structure of the present invention uses a composite manufacturing technology combining two-photon polymerization and deposition technology, according to the three-dimensional model of the designed three-dimensional multicellular micro-nano structure, using The second laser scans the liquid polymer layer by layer to make it polymerize to form a three-dimensional polymer micro-nano structure, and then deposit multi-layer metal on the surface of the polymer to form a composite metal layer with gradient changes in mechanical properties, and prepare a high-strength and tough The multicellular metal micro-nano structure comprises the following steps:

[0024] Establishment of 3D model of micro / nano structure: establish a 3D model of 3D multicellular micro / nano structure, and use model layering software to discretely layer it;

[0025] Preparation of p...

Embodiment 1

[0042] Establishment of the 3D model of the micro-nano structure: design the 3D model of the micro-nano structure, and use Solidworks software to discretely layer it.

[0043] Preparation of photosensitive resin: prepare liquid polymer, i.e. photosensitive resin, said photosensitive resin includes methyl methacrylate, polydipentaerythritol hexaacrylate and photoinitiator, methyl methacrylate, polydipentaerythritol hexaacrylate and photoinitiator Mix according to the mass ratio of 49:49:2;

[0044]Selection of laser processing system: select laser processing system, including femtosecond laser, optical transmission control device, confocal real-time monitoring device, three-dimensional mobile platform and control device;

[0045] Setting of two-photon polymerization process parameters: set two-photon polymerization process parameters, pulse width 80fs, average pulse energy 0.10nJ, repetition frequency 80MHz, scan rate 5mm / s, focus diameter 0.35μm, scan step 0.4μm;

[0046] Pre...

Embodiment 2

[0049] Establishment of the 3D model of the micro-nano structure: Design the 3D model of the micro-nano structure, and use Solidworks software to discretely layer it.

[0050] Preparation of photosensitive resin: prepare liquid polymer, that is, photosensitive resin, which includes butyl methacrylate, propoxylated trimethylolpropane triacrylate and photoinitiator; butyl methacrylate, propoxy Trimethylolpropane triacrylate and photoinitiator are mixed according to the mass ratio of 36:56:8;

[0051] Selection of laser processing system: select laser processing system, including femtosecond laser, optical transmission control device, confocal real-time monitoring device, three-dimensional mobile platform and control device;

[0052] Two-photon polymerization process parameter setting: set two-photon polymerization process parameters, pulse width 80fs, average pulse energy 0.15nJ, repetition frequency 80MHz, scan rate 5mm / s, focus diameter 0.35μm, scan step 0.5μm;

[0053] Prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com