Method for separating phorbol by utilizing ultrasonic-assisted alcoholysis-extraction coupling technology

A technology of ultrasonic wave and phorbol alcohol, which is applied in the field of ultrasonic-assisted alcoholysis-extraction coupling technology to separate phorbol alcohol. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

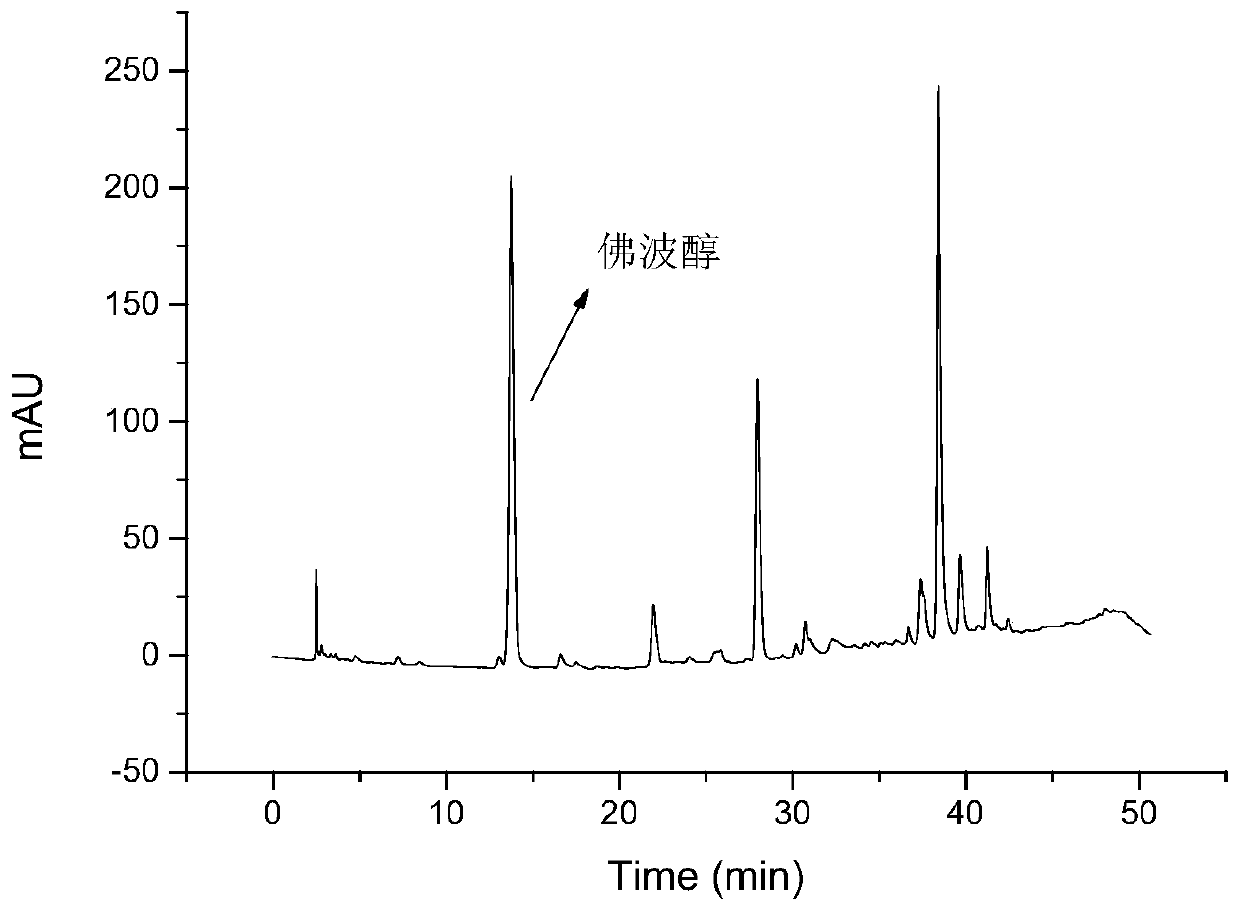

Image

Examples

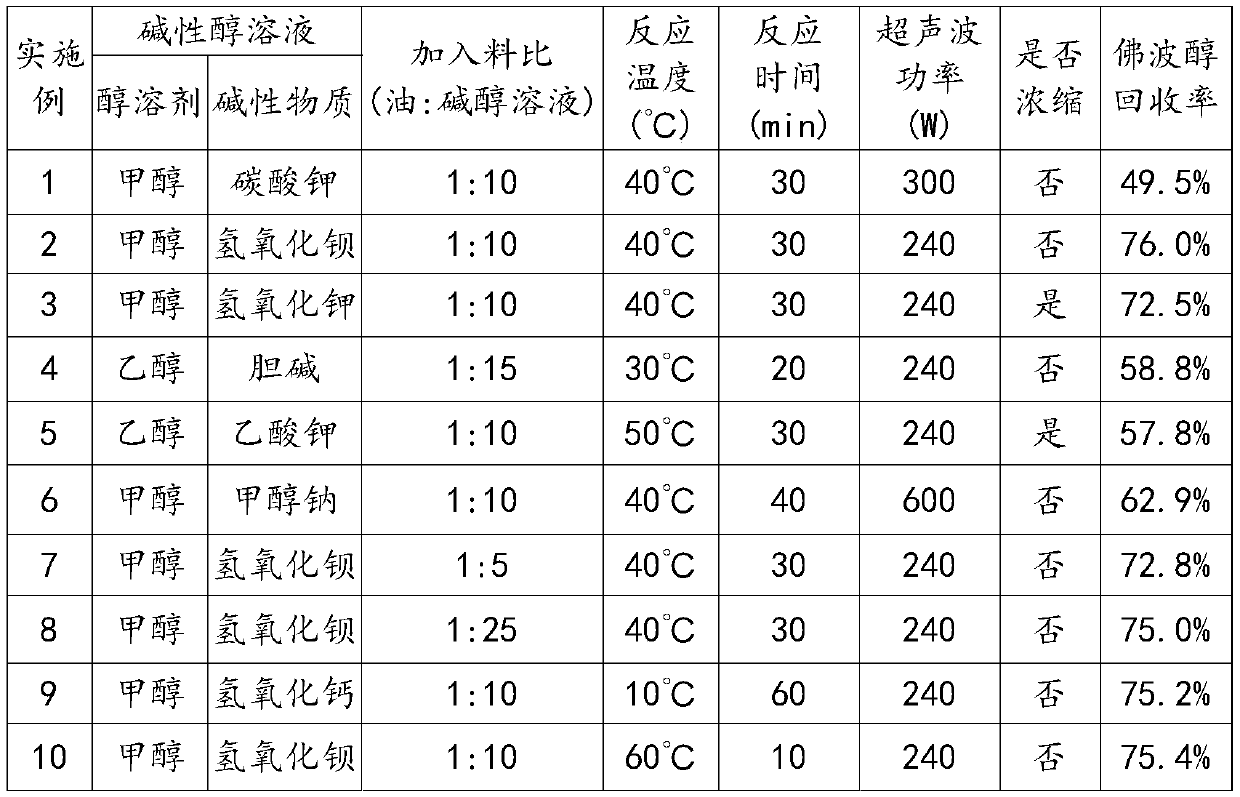

Embodiment 1

[0027] Preparation of S1 saturated alkaline methanol solution: Add enough anhydrous potassium carbonate to methanol with a content of ≥99%, reflux in a water bath at 70°C for 2 hours, and prepare a saturated potassium carbonate-methanol solution for use;

[0028] Preparation of S2 acidic methanol solution: Add 10% volume of concentrated hydrochloric acid to 1 volume content ≥99% of methanol and mix it evenly to prepare a hydrochloric acid-methanol mixed solution for use;

[0029] S3 alcoholysis-extraction: accurately measure 1ml of croton oil in a 15ml centrifuge tube, add potassium carbonate-methanol saturated solution according to the material-to-liquid ratio of 1:10, shake and shake, under the conditions of ultrasonic power of 300W and temperature of 40℃ Extract for 30min. Set aside for separation to obtain the upper clear liquid and the lower oil phase liquid;

[0030] S4 Adjust pH: Take the supernatant liquid and the mixed solution of hydrochloric acid-methanol with a needle, a...

Embodiment 2

[0033] Preparation of S1 saturated alkaline methanol solution: Add sufficient anhydrous barium hydroxide to methanol with a content of ≥99%, reflux in a water bath at 70°C for 2 hours to prepare a saturated solution of barium hydroxide-methanol for use;

[0034] Preparation of S2 acidic methanol solution: Add 10% volume of concentrated hydrochloric acid to 1 volume content ≥99% of methanol and mix it evenly to prepare a hydrochloric acid-methanol mixed solution for use;

[0035] S3 alcoholysis-extraction: accurately measure 1ml of croton oil and place it in a 15ml centrifuge tube, add a saturated solution of barium hydroxide-methanol according to the material-to-liquid ratio of 1:10, shake and shake it evenly, the ultrasonic power is 240W, the temperature is 40℃ Extract for 30min under conditions. Set aside for separation to obtain the upper clear liquid and the lower oil phase liquid;

[0036] S4 repeated extraction: remove the lower oil phase liquid and continue alcoholysis-extrac...

Embodiment 3

[0041] Preparation of S1 saturated alkaline methanol solution: Add sufficient anhydrous potassium hydroxide to methanol with a content of ≥99%, reflux in a water bath at 70°C for 2 hours, and prepare a saturated potassium hydroxide-methanol solution for use;

[0042] Preparation of S2 acidic methanol solution: Add 10% volume of concentrated hydrochloric acid to 1 volume content ≥99% of methanol and mix it evenly to prepare a hydrochloric acid-methanol mixed solution for use;

[0043] S3 alcoholysis-extraction: accurately measure 50ml of croton oil in a 2000ml beaker, add a saturated solution of potassium hydroxide-methanol according to the material-to-liquid ratio of 1:10, shake and shake, under the condition of ultrasonic power of 240W and temperature of 40℃ Extract for 30min. Transfer to a separatory funnel, stand still and separate to obtain the upper clear liquid and the lower oil phase liquid;

[0044] S4 repeated extraction: remove the lower oil phase liquid and continue alcoh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com