Antibacterial and mildew-proof coating and preparation method and application thereof

An antibacterial, antifungal and coating technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc. Mildew effect, bactericidal and mildew-proof advantages and lasting power, the effect of strong compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

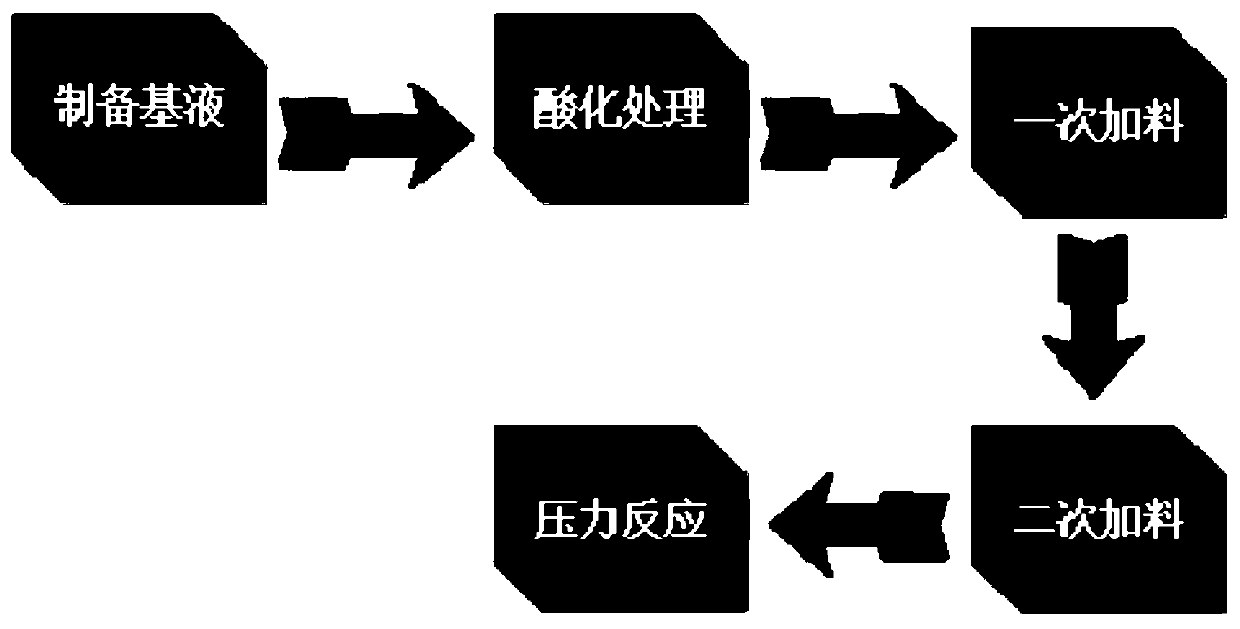

Method used

Image

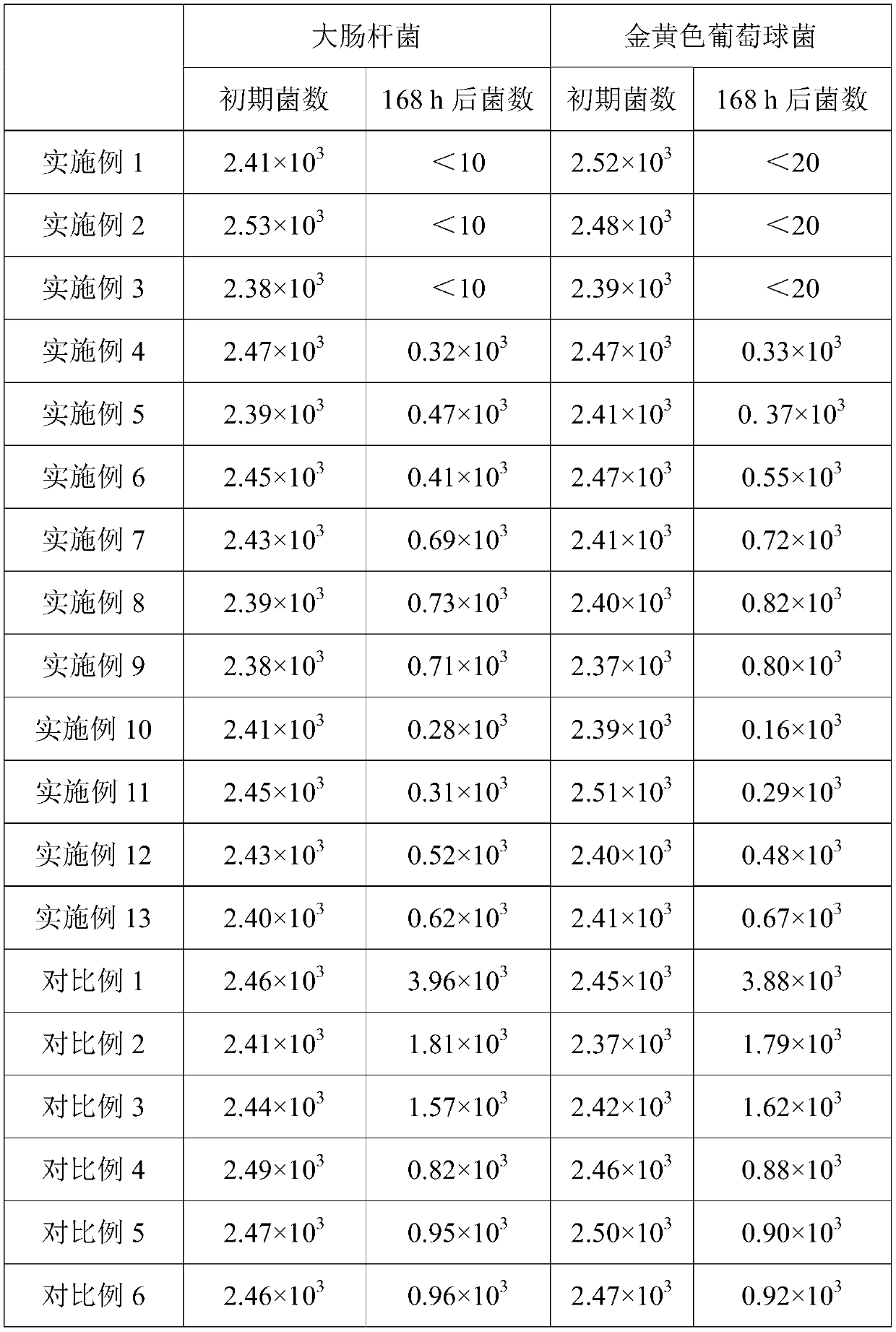

Examples

Embodiment 1

[0091] The present embodiment provides an antibacterial and mildew-proof coating, and the preparation raw materials of the antibacterial and mildew-proof coating include by weight: 20.5 parts of polyvinyl alcohol (the degree of polymerization is 2000), 0.8 part of sodium tripolyphosphate, 2.7 parts of glycerin 76 parts of deionized water, 5 parts of 80g / L oxalic acid, 12 parts of ultrafine sharp titanium dioxide with a fineness of 2 μm, 8 parts of ultrafine wollastonite with a fineness of 2 μm, and 8 parts of superfine calcium carbonate parts, 24 parts of water-based styrene-acrylic emulsion (viscosity is 1000mPa·s) of 45wt% solid content, 10 parts of antibacterial agent and 5 parts of benzyl alcohol;

[0092] Described antimicrobial agent is the mixture of ultrafine copper yttrium alloy powder and sodium isozincate powder, and the molar mass ratio of described ultrafine copper yttrium alloy powder and sodium isozincate powder is 1.8:1, and in described copper yttrium alloy pow...

Embodiment 2

[0104] The present embodiment provides a kind of antibacterial and mildew-proof coating, and the preparation raw material of described antibacterial and mildew-proof coating comprises by weight: 28 parts of polyvinyl alcohol (the degree of polymerization is 1000), 1 part of sodium tripolyphosphate, 5 parts of glycerin 66 parts of deionized water, 4 parts of oxalic acid 90g / L, 18 parts of ultrafine sharp titanium dioxide with a fineness of 5 μm, 9 parts of ultrafine wollastonite with a fineness of 4 μm, and 10 parts of superfine calcium carbonate parts, 30 parts of water-based styrene-acrylic emulsion (viscosity is 800mPa·s) of 40wt% solid content, 20 parts of antibacterial agents and 10 parts of benzyl alcohol;

[0105] Described antimicrobial agent is the mixture of ultrafine copper yttrium alloy powder and sodium isozincate powder, and the molar mass ratio of described ultrafine copper yttrium alloy powder and sodium isozincate powder is 2:1, and in described copper yttrium a...

Embodiment 3

[0117] The present embodiment provides an antibacterial and antifungal coating, the preparation raw materials of the antibacterial and antifungal coating include by weight: 30.8 parts of polyvinyl alcohol (the degree of polymerization is 4000), 1.7 parts of sodium tripolyphosphate, 6.5 parts of glycerin 61 parts of deionized water, 5 parts of 100g / L oxalic acid, 23 parts of ultrafine sharp titanium dioxide with a fineness of 10 μm, 11 parts of ultrafine wollastonite with a fineness of 2 μm, and 11 parts of superfine calcium carbonate, 36 parts of water-based styrene-acrylic emulsion (viscosity is 1500mPa·s), 25 parts of antibacterial agent and 12 parts of benzyl alcohol with solid content of 40wt%;

[0118] Described antimicrobial agent is the mixture of ultrafine copper yttrium alloy powder and sodium isozincate powder, and the molar mass ratio of described ultrafine copper yttrium alloy powder and sodium isozincate powder is 2:1, and in described copper yttrium alloy powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com