Flexible UV photocureable coating, and preparation method and application thereof

A light-curing coating and flexible technology, which is applied in the direction of epoxy resin coating, polyurea/polyurethane coating, coating, etc., can solve the problem of coating flexibility, insufficient aging resistance, damage to the health of operators, and hidden dangers of production safety, etc. problems, to achieve the effect of easy coating dispersion, good elasticity, and increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0035] (a) Mix toluene diisocyanate and dibutyltin dilaurate into the reactor at a molar ratio of 1:0.01, raise the temperature to 40°C, and then drop pentaerythritol triacrylate containing the polymerization inhibitor p-hydroxyanisole (to ensure -NCO :-OH molar ratio=2:1), reacted at 40°C for 4h;

[0036] (b) Add a certain amount of dialkyl silicone oil (-NCO:-OH molar ratio = 1:1), continue to heat up to 70-75°C, and test the reaction product by Fourier transform infrared spectrum until the -NCO reaction is complete , stop the reaction to obtain the photocurable silicone acrylate.

preparation example 5

[0045] (a1) Add 2 mol of hexamethylene diisocyanate and catalyst dibutyltin laurate into the reaction kettle, raise the temperature to 40-50°C, and slowly drop 1 mol of polybutadiene diol into the In the reaction kettle, after reacting for 1 hour, the temperature was raised to 60°C;

[0046] (b1) Add 2 mol each of hydroxy acrylate and hydroquinone as a polymerization inhibitor, heat up to 70-80°C, test the reaction product by Fourier transform infrared spectrum until the -NCO infrared peak disappears completely, and at the same time, in order to reduce the viscosity of polyurethane After finishing, add 20% tripropylene glycol diacrylate to dilute, and stir evenly to obtain polybutadiene urethane acrylate.

Embodiment 1

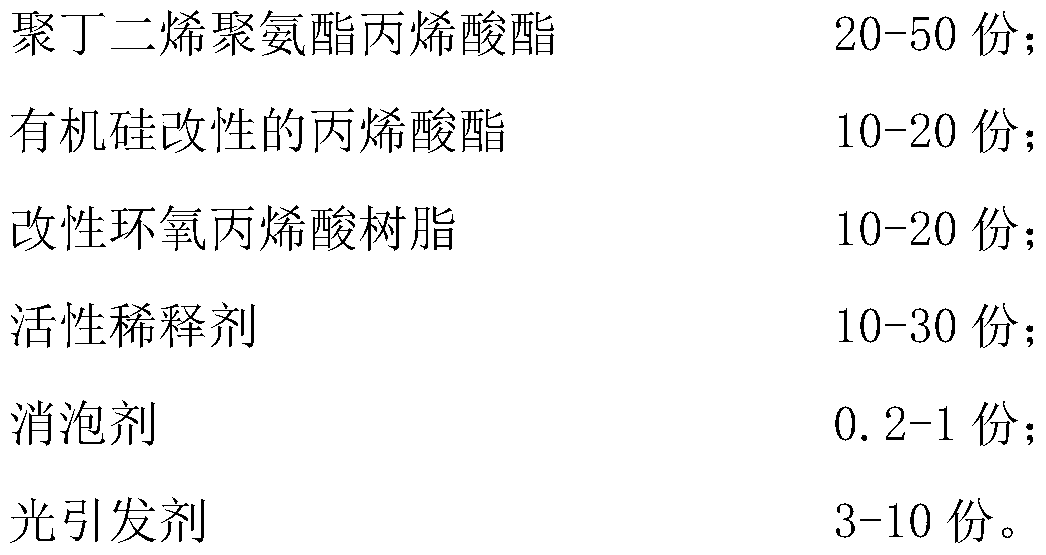

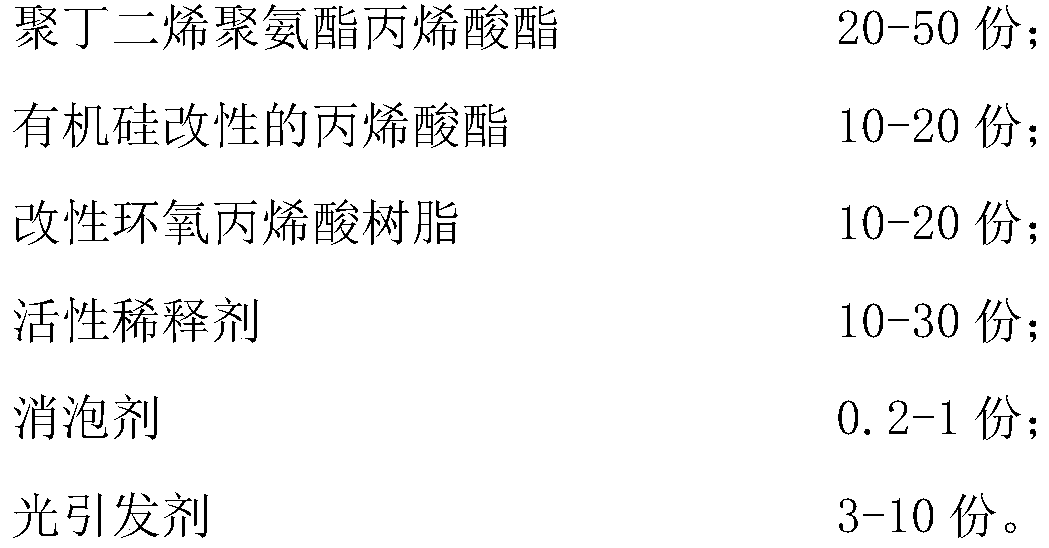

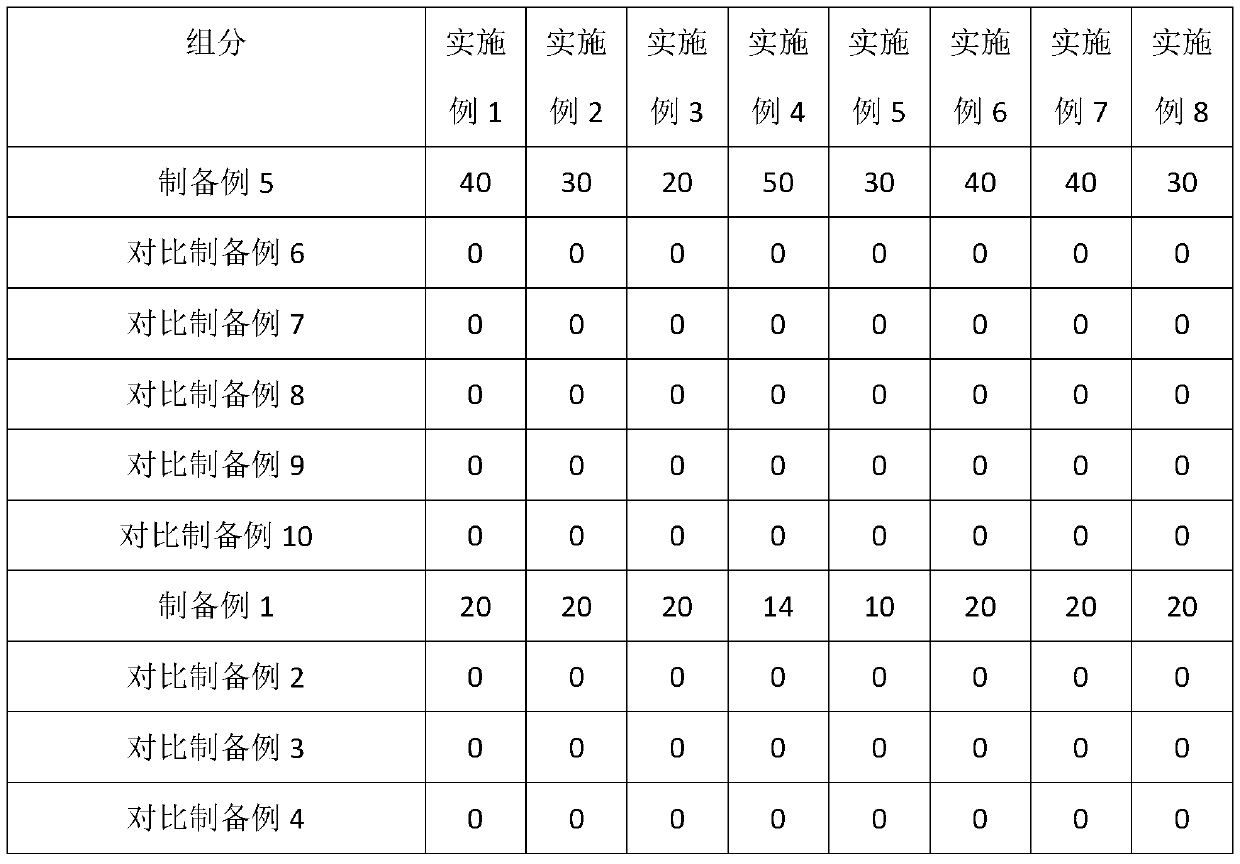

[0059] A kind of ultra-flexible UV photocuring coating, its component in parts by weight is as shown in table 1;

[0060] The preparation steps of the coating described in this example are as follows: first preheat 400g of polybutadiene urethane acrylate, 200g of silicone modified acrylate and 100g of modified epoxy acrylate in an oven at 60°C for 6h, Increase the fluidity of the resin, then add it to the reaction kettle, then add 215g of isobornyl acrylate (IBOA), stir at 600r / min for 1-2h, after stirring evenly, add 80g of 2-hydroxy-2- Methyl-1-phenyl-1-propanone (1173) and 5 g of defoamer were stirred at 300 r / min and dispersed for 0.5 h to obtain the coating.

[0061] In the present invention, the UV photocurable coating is applied by spraying. Use a spray gun to spray a uniform paint film on the specified sample plate, without blanks and overflows. When spraying, the distance between the spray gun and the surface to be coated should not be less than 100mm, and the sprayi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com