Medical recombinant collagen spray and preparation method thereof

A recombinant collagen, a certain amount of technology, applied in medical science, bandages, etc., can solve the problems of rejection, uncertain molecular weight, wide distribution, and hidden dangers of animal viruses, etc., to achieve easy portability, promote wound repair, and accelerate The effect of epidermal cell migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

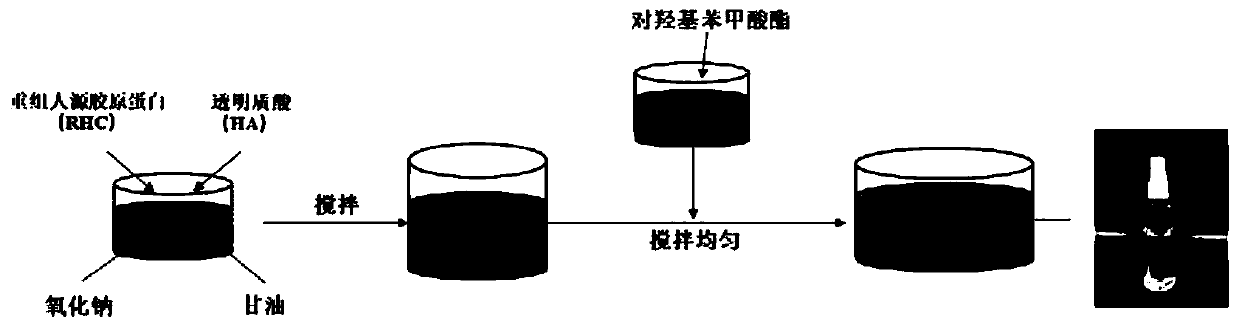

[0023] Embodiment 1 Preparation of medical recombinant collagen spray 1

[0024] Weigh 7.164g disodium hydrogen phosphate (Na2HPO4.12H2O) and dissolve it in 100ml deionized water. Weigh 3.121g of sodium dihydrogen phosphate (NaH2PO4.2H2O) and dissolve it in 100ml of deionized water. Mix 61ml of disodium hydrogen phosphate aqueous solution with 39ml of sodium dihydrogen phosphate aqueous solution to obtain a 0.2M / L buffer solution with a pH of 7.0. Weigh 0.07g of recombinant human collagen, 0.01g of hyaluronic acid, 0.9g of sodium chloride, and 5.42ml of glycerin into 94.18ml of buffer solution, and fully dissolve on a magnetic stirrer at 1000r / min at 37°C. Weigh 0.06g of methylparaben and 0.01g of ethylparaben in 400ul of phenoxyethanol, and dissolve completely in a 37°C water bath. Add the phenoxyethanol dissolved in methylparaben and ethylparaben to the previously prepared recombinant human collagen and hyaluronic acid solution, stir well, and then ultrasonically debubble ...

Embodiment 2

[0025] Embodiment 2 Preparation 2 of medical recombinant collagen spray

[0026] Weigh 7.164g disodium hydrogen phosphate (Na2HPO4.12H2O) and dissolve it in 100ml deionized water. Weigh 3.121g of sodium dihydrogen phosphate (NaH2PO4.2H2O) and dissolve it in 100ml of deionized water. Mix 61ml of disodium hydrogen phosphate aqueous solution with 39ml of sodium dihydrogen phosphate aqueous solution to obtain a 0.2M / L buffer solution with a pH of 7.0. Weigh 0.1g of recombinant human collagen, 0.02g of hyaluronic acid, 0.9g of sodium chloride, and 3.24ml of glycerin into 96.396ml of buffer solution, and fully dissolve on a magnetic stirrer at 1000r / min at 37°C. Weigh 0.03g of methylparaben and 0.03g of ethylparaben, dissolve them in 364ul of phenoxyethanol, and dissolve them completely in a 37°C water bath. Add the phenoxyethanol dissolved in methylparaben and ethylparaben to the previously prepared recombinant human collagen and hyaluronic acid solution, stir well, and then ultr...

Embodiment 3

[0027] Embodiment 3 Preparation of medical recombinant collagen spray 3

[0028]Weigh 7.164g disodium hydrogen phosphate (Na2HPO4.12H2O) and dissolve it in 100ml deionized water. Weigh 3.121g of sodium dihydrogen phosphate (NaH2PO4.2H2O) and dissolve it in 100ml of deionized water. Mix 61ml of disodium hydrogen phosphate aqueous solution with 39ml of sodium dihydrogen phosphate aqueous solution to obtain a 0.2M / L buffer solution with a pH of 7.0. Weigh 0.1g of recombinant human collagen, 0.022g of hyaluronic acid, 0.9g of sodium chloride, and 4.10ml of glycerin into 95.52ml of buffer solution, and fully dissolve on a magnetic stirrer at 1000r / min at 37°C. Weigh 0.01g of methylparaben and 0.06g of ethylparaben in 380ul of phenoxyethanol, and dissolve completely in a 37°C water bath. Add the phenoxyethanol dissolved in methylparaben and ethylparaben to the previously prepared recombinant human collagen and hyaluronic acid solution, stir well, and then ultrasonically debubble a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com