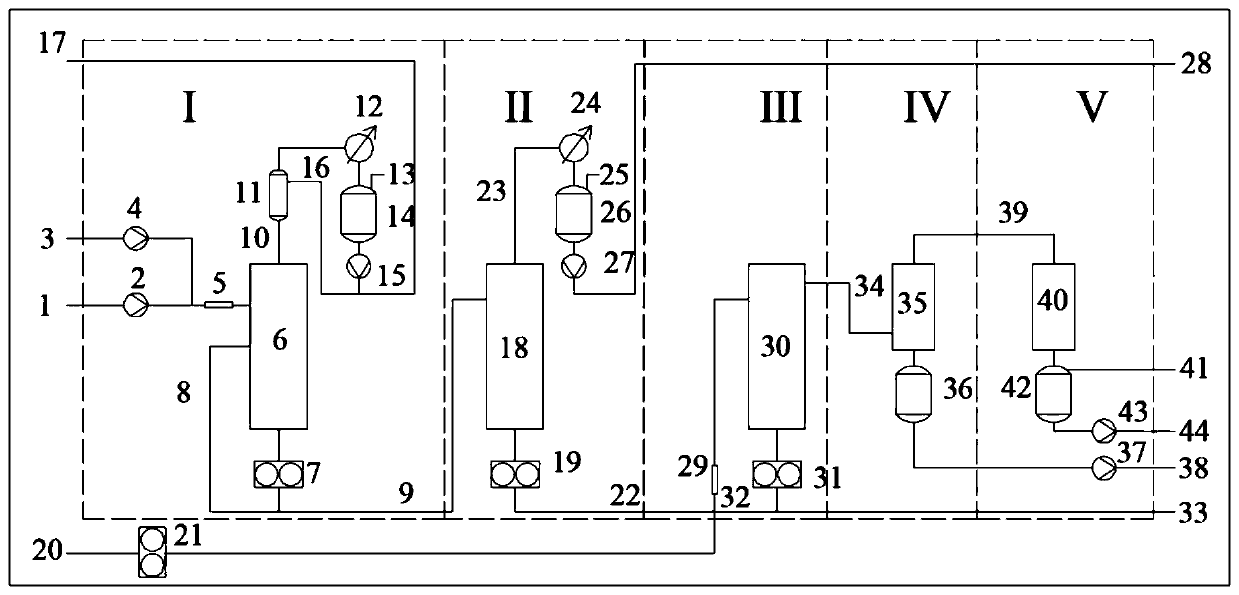

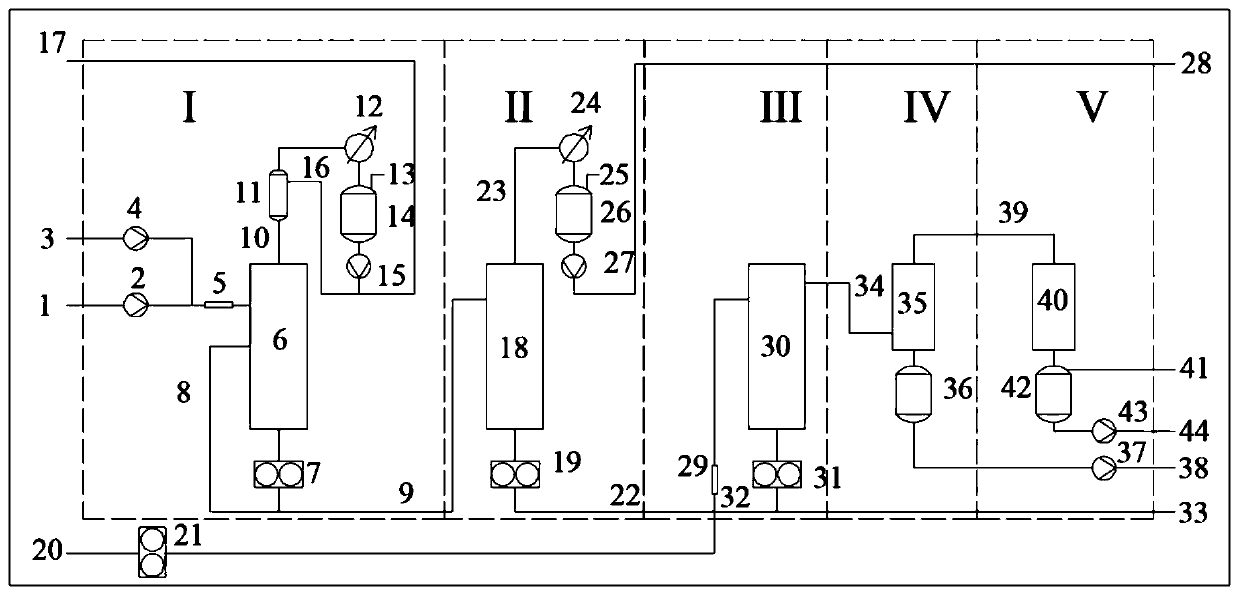

Synthesis method and device for rapidly producing lactide at high yield

A synthesis device and synthesis method technology, applied in chemical instruments and methods, sub-atmospheric process, organic chemistry, etc., can solve the problems of high cost, long residence time, low efficiency, etc., and achieve high yield and simple operation , high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The 90% L-lactic acid raw material 1 enters the oligomerization reactor 6 at a flow rate of 10 g / h through the raw material pump 2. The oligomerization reactor 6 is a TLNS falling film reactor, and the operating conditions of the reactor are 80° C. and 1 KPa absolute pressure. Dehydration and oligomerization, the dehydration oligomers pass through the oligomerization discharge / circulation pump 7 to control the reflux ratio of 1000:1, and return to the side line feed port of the oligomerization reactor 6 to continue the reaction, and the rectification tower 11 at the top of the oligomerization reactor 6 returns lactic acid , Control the tower top temperature to 40°C by reflux. Oligomer 9 has a molecular weight of 500 Da.

[0052] The oligomer 9 enters the oligomer purification reactor 18, which is an RFJL packed rectification column with side feed, and the operating conditions are: absolute pressure 1KPa, tower top temperature 20°C. The removed acid, water and dimer are...

Embodiment 2

[0057] The 90% L-lactic acid raw material 1 is mixed with the catalyst zinc oxide 3 by the raw material pump 2 at a flow rate of 20g / h and then enters the oligomerization reactor 6. The oligomerization reactor 6 is a TLNS falling film reactor, and the operating condition of the reactor is a temperature of 120°C 1. Carry out dehydration and oligomerization under the condition of absolute pressure 1KPa, the dehydration oligomer passes through the oligomerization discharge / circulation pump 7 to control the reflux ratio of 300:1, and returns to the side feed port of the oligomerization reactor 6 to continue the reaction, and the oligomerization reactor 6 Lactic acid is refluxed in the top rectifying column 11, and the temperature at the top of the column is controlled to 60° C. by reflux. Oligomer 9 has a molecular weight of 1100 Da.

[0058] The oligomer 9 enters the oligomer purification reactor 18, which is an RFJL packed rectification column with side feed, and the operating c...

Embodiment 3

[0063]The 90% L-lactic acid raw material 1 is mixed with the catalyst zinc acetate 3 at a flow rate of 50g / h by the raw material pump 2 and then enters the oligomerization reactor 6. The oligomerization reactor 6 is a WEF thin film evaporation reactor, and the operating condition of the reactor is a temperature of 180°C 1. Carry out dehydration and oligomerization under the condition of absolute pressure 100KPa, the dehydration oligomer passes through the oligomerization discharge / circulation pump 7 to control the reflux ratio of 20:1, and returns to the side feed port of the oligomerization reactor 6 to continue the reaction, and the oligomerization reactor 6 Lactic acid is refluxed in the top rectifying column 11, and the temperature at the top of the column is controlled to 70° C. by reflux. Oligomer 9 has a molecular weight of 800 Da.

[0064] The oligomer 9 enters the oligomer purification reactor 18, which is an RFJL packed rectification column with side feed, and the op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com