Lignin-free coal water slurry additive and coal water slurry prepared therefrom

A coal-water slurry and additive technology, which is used in fuel additives, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems affecting the preparation of coal slurry additives and insufficient supply of lignin raw materials, and achieves enhancement of electrostatic repulsion and improvement of hydrophilicity. Sex, resolving ineffective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

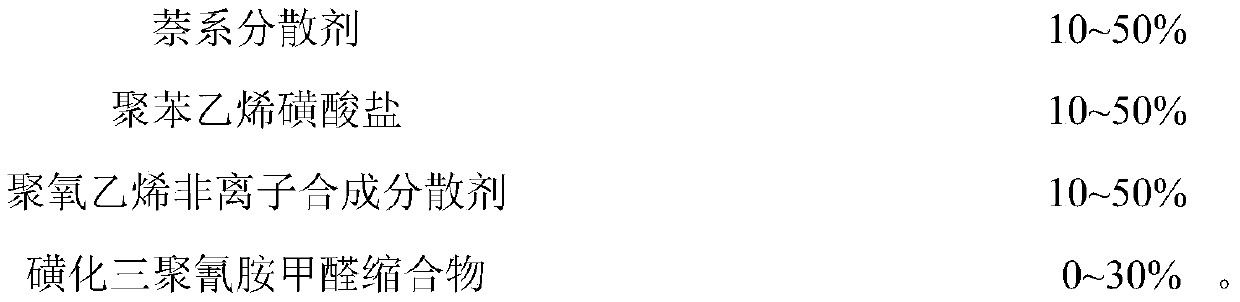

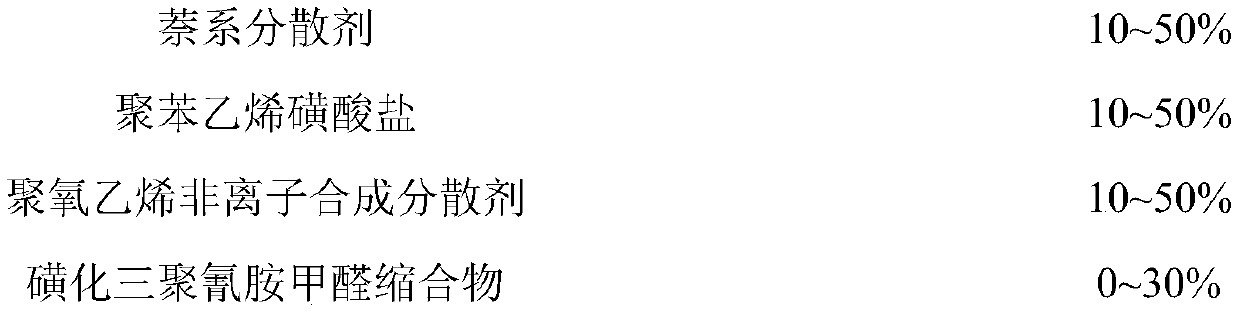

[0028] At normal temperature and pressure, 30wt% of naphthalenesulfonic acid formaldehyde condensate, 30wt% sodium polystyrene sulfonate, 20wt% alkylphenol polyoxyethylene ether and 20wt% sulfonated melamine formaldehyde condensate were mixed in In the reaction container, add water to dilute and stir for 30-60 minutes until the stirring is uniform, and a liquid coal-water slurry additive with a solid content of 30% is obtained.

Embodiment 2

[0030] Under normal temperature and pressure, 40wt% naphthalenesulfonic acid formaldehyde condensate, 20wt% sodium polystyrene sulfonate, 10wt% alkylphenol polyoxyethylene ether and 30wt% sulfonated melamine formaldehyde condensate are mixed in In the reaction container, add water to dilute and stir for 30-60 minutes until the stirring is uniform, and a liquid coal-water slurry additive with a solid content of 30% is obtained.

Embodiment 3

[0032] Under normal temperature and pressure, mix 50wt% naphthalenesulfonic acid formaldehyde condensate, 35wt% sodium polystyrene sulfonate, and 15wt% alkylphenol polyoxyethylene ether in a reaction vessel, dilute with water and stir for 30- 60 minutes until the mixture is evenly stirred to obtain a liquid coal-water slurry additive with a solid content of 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com