Multi-element pre-melting refining slag, production method thereof and production device thereof

A technology for refining slag and premelting, applied in the field of multi-component premelting refining slag, can solve the problems of effect influence, slow slag formation, long refining time, etc., and achieve the effect of improving production efficiency, good ductility, and saving mineral resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

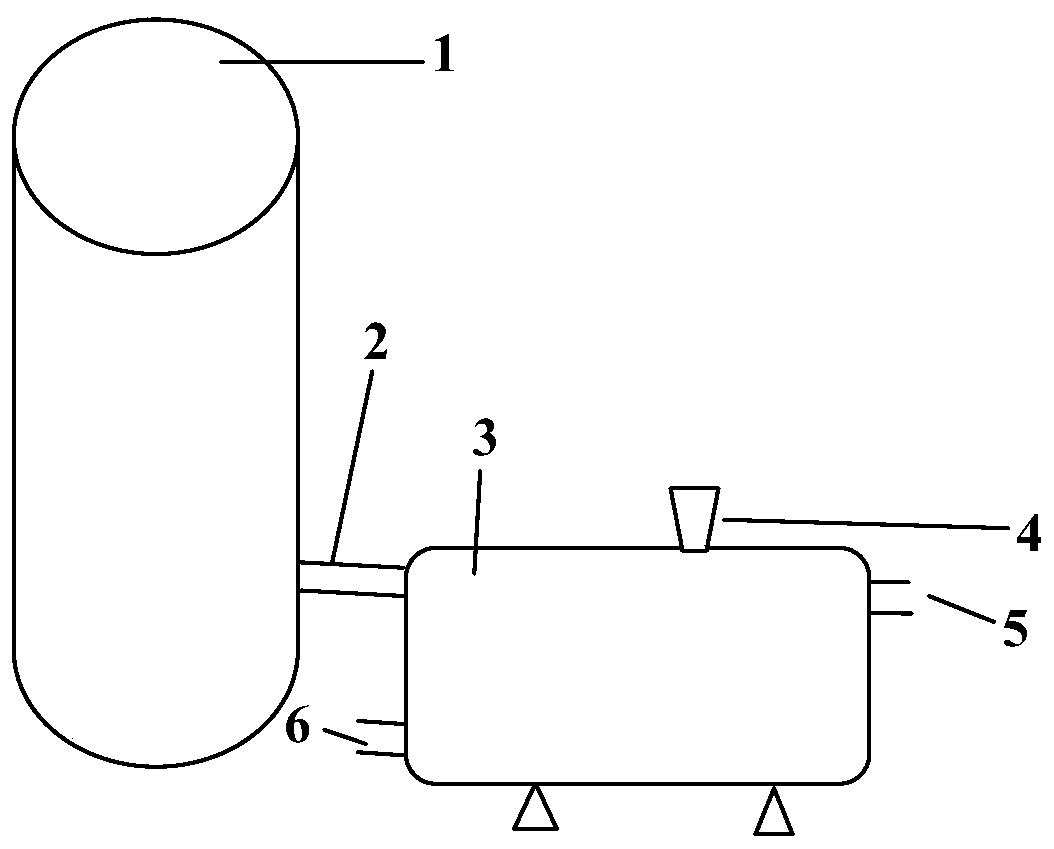

[0040] A device for producing multi-element premelted refining slag, said device comprising a shaft furnace 1;

[0041] The water outlet 2 of the shaft furnace 1 is connected with the stirring tank 3 provided with an insulating layer, and the insulating layer prevents heat loss;

[0042] The thermal insulation layer of the stirring tank 3 is provided with a thermocouple, and the stirring tank 3 is provided with an electric heating device, which is activated when the temperature is low to supplement heat and increase the temperature;

[0043] The feeding port 4 is arranged above the stirring tank 3;

[0044] The upper air inlet 5 and the lower air inlet 6 are arranged on the mixing tank 3 in opposite directions.

Embodiment 2

[0046] A method utilizing the device described in embodiment 1 to produce multi-element premelted refining slag, said method comprising the steps of:

[0047] The wollastonite tailings are crushed into 80-120mm blocks, impurities are removed by flotation, and the chemical composition of the wollastonite tailings is detected as: SiO 2 55.61wt%, CaO 29.93wt%, MgO 2.24wt%, Al 2 o 3 0.21wt%, loss on ignition 10.23wt%;

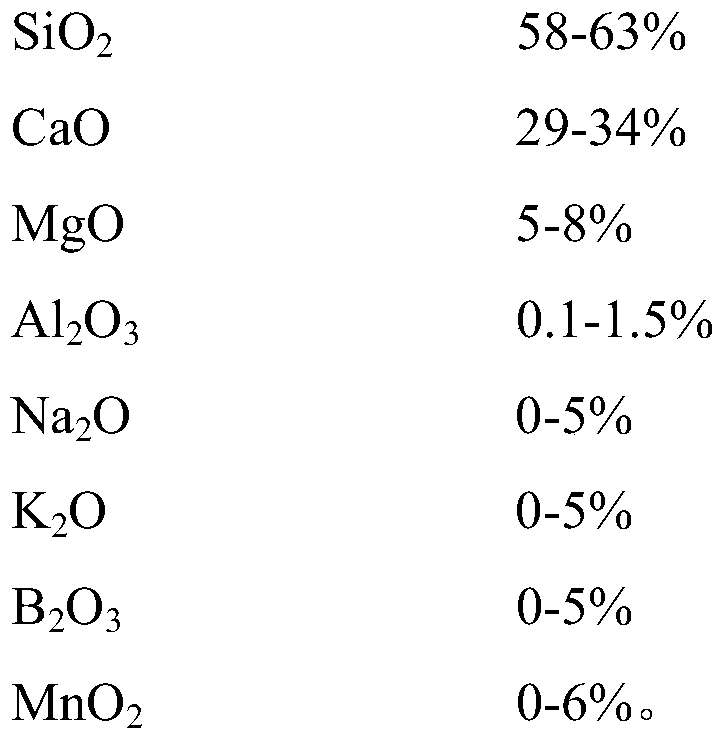

[0048] Put wollastonite tailings raw material into shaft furnace 1, use coke (ash content 10.5%) as fuel for melting, use air as coke combustion support, and release heat from coke combustion in the oxidation zone (or melting zone), and the temperature in this zone can reach 1450 -1720°C, the downward moving raw material is heated and melted into a melt, and the melt is sampled to detect the chemical composition as SiO 2 62.93wt%, CaO3 3.43wt%, MgO 2.58wt%, Al 2 o 3 1.02wt%, ∑: 99.95wt%;

[0049] The molten liquid enters the mixing tank 3 through the wate...

Embodiment 3

[0054] A method utilizing the device described in embodiment 1 to produce multi-element premelted refining slag, the difference from embodiment 2 is:

[0055] The powdery material is: soda ash with a particle size of 100 mesh, dolomite powder with a particle size of 100 mesh, and quartz powder with a particle size of 200 mesh. The chemical composition is shown in Table 1. According to the quality of the molten liquid, the molten liquid, soda ash, dolomite powder and quartz powder Calculate the addition amount of various powder materials according to the mass ratio of 57:7:21:15;

[0056] Control the flow rate of stirring gas 13m 3 / min, air pressure 0.5MPa, jet speed 6m / s, stirring the molten liquid for 10min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com