A kind of antibacterial fiber composition and its fabric and application

An antibacterial fiber and composition technology, which is applied to the antibacterial fiber composition and its fabrics and application fields, can solve problems such as hidden safety hazards, recovery pain and injury of traumatized individuals, and slow-drying water release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

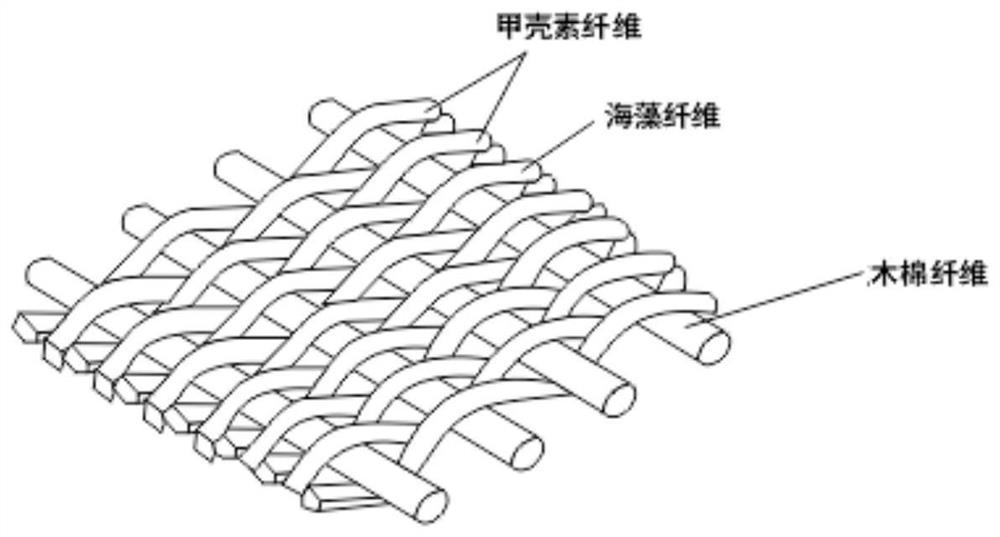

[0064] An antibacterial fiber composition comprises the following components in parts by weight: 45 parts of chitin cellulose, 15 parts of seaweed fiber and 30 parts of kapok fiber.

[0065] The above-mentioned antibacterial fiber composition is prepared by a Tsudakoma ZW408 water-jet loom to prepare a plain weave fabric, and the transverse fibers of the fabric are arranged as two chitin fibers and one seaweed fiber, which are circulated successively; the longitudinal fibers are kapok fibers, specifically as figure 1 shown. The count of each component of the fabric is 60 (English count), the warp yarn density of the fabric is 65 warp yarns per square inch, and the weft yarn density of the fabric is 78 weft yarns per square inch.

[0066] Process parameters for controlling the Tsudakoma ZW408 water-jet loom: 9kg weight, 355° flat heald angle, 85mm rear beam position, 85° jet angle, 182cm length measurement, 200° flight angle, and 200° leading water 80mm, let-off tension spring...

Embodiment 2

[0068] An antibacterial fiber composition comprises the following components in parts by weight: 50 parts of chitin cellulose, 20 parts of seaweed fiber and 40 parts of kapok fiber.

[0069] The above-mentioned antibacterial fiber composition is prepared plain weave fabric according to the method for embodiment 1.

Embodiment 3

[0071] An antibacterial fiber composition comprises the following components in parts by weight: 45 parts of chitin cellulose, 15 parts of seaweed fiber and 30 parts of modified kapok fiber.

[0072] The preparation of modified kapok fiber comprises the following steps:

[0073] (1) Chitosan imine, surfactant and nanocellulose are mixed by mass ratio 3:2:1, be mixed with the modified solution that mass fraction is 15%, pH value is 8;

[0074] (2) Immerse the kapok fiber in the modification solution at a mass volume ratio of 1:15g / mL for 20 minutes at an immersion temperature of 40°C, take it out, and dry it to obtain the product.

[0075] Antibacterial fiber composition is prepared plain weave fabric according to the method for embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com