Magnesium-air battery negative electrode surface modification method and electrolyte

A technology of surface modification and air battery, which is applied to the electrodes of primary batteries, battery electrodes, and aqueous electrolytes, and can solve problems such as failure to improve the hysteresis behavior of the discharge voltage of the magnesium negative electrode, many steps in the chemical conversion film, and aggravate the hysteresis behavior. Achieve the effects of shortening the battery preparation cycle, simple components, and increasing the working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

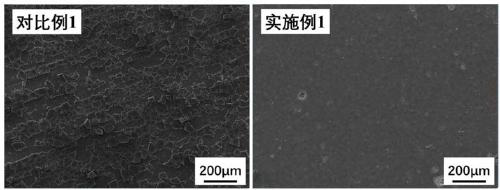

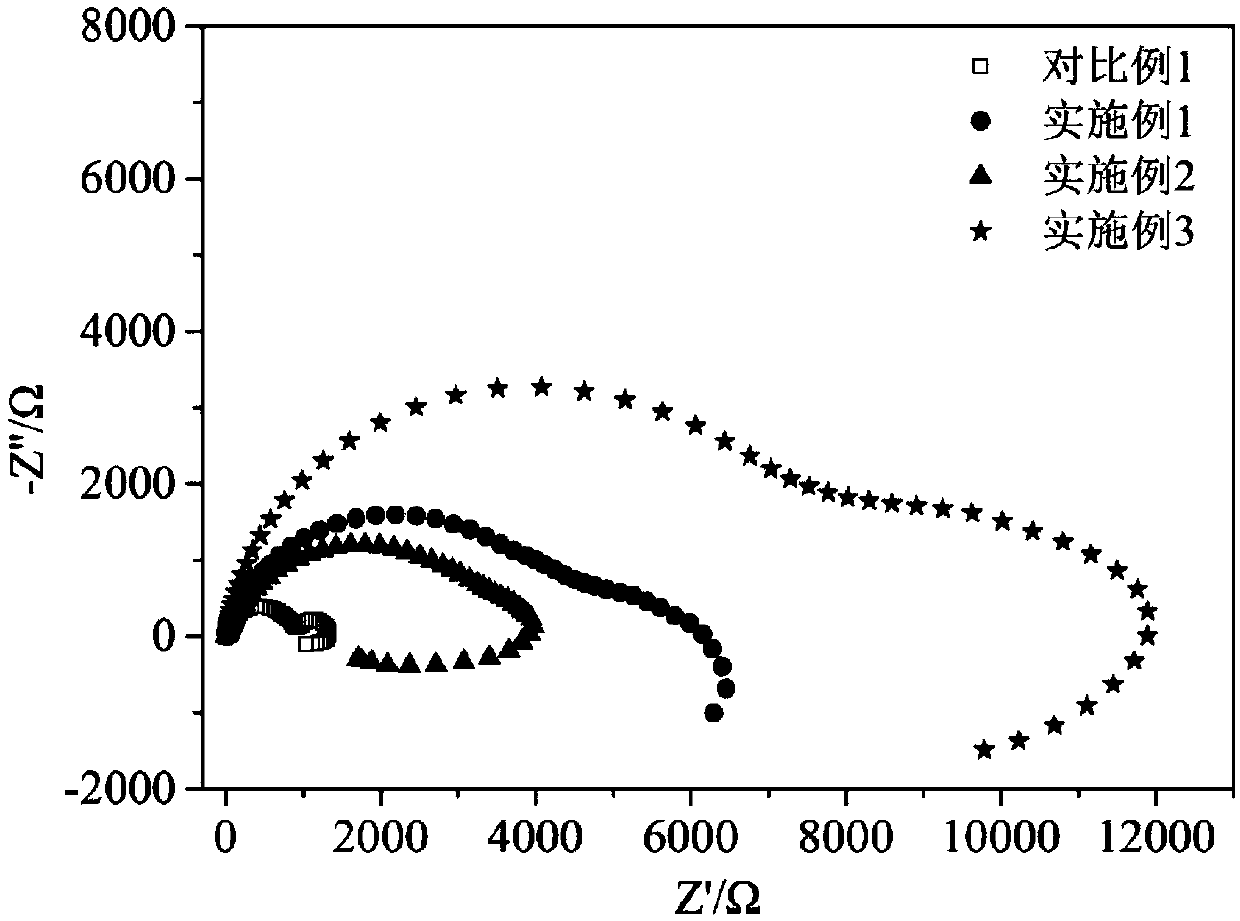

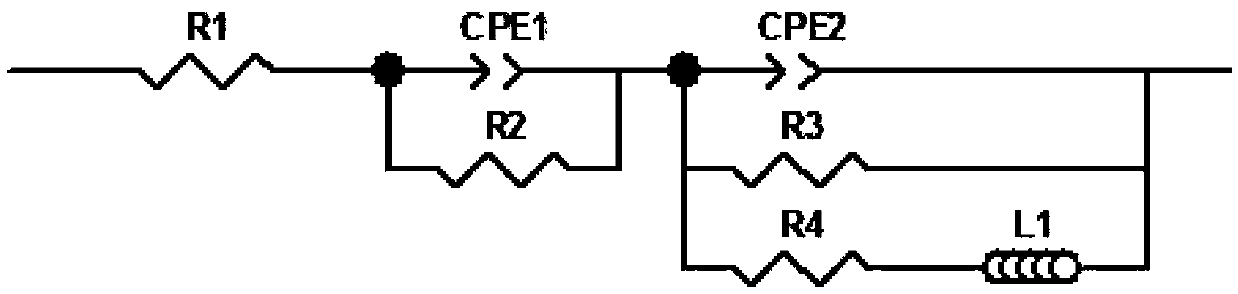

Embodiment 1

[0024] The electrolyte solution used in this embodiment is composed of electrolyte solution A (2mol L -1 Magnesium nitrate+0.2mol·L -1 Magnesium sulfate+0.02mol·L -1 Ammonium dihydrogen phosphate) and electrolyte composition B (2mol L -1 Magnesium nitrate+0.2mol·L -1 Magnesium sulfate+0.02mol·L -1 ammonium molybdate) mixed in a volume ratio of 3:7. The negative electrode material is AZ31B magnesium alloy, the surface adopts a cycle potential range of -0.5~2.0V, the number of scans is 5 times, and the scan speed is 0.03V s -1 The cyclic voltammetry parameter is used to plate polyaniline film, and the electroplating solution is 0.2mol L-1 Aniline+0.5mol·L -1 sodium salicylate. After coating, soak in the electrolyte for 1 day, and then test the surface morphology, impedance value, and discharge performance of the magnesium negative electrode.

Embodiment 2

[0028] The electrolyte solution used in this embodiment is composed of electrolyte solution A (2mol L -1 Magnesium nitrate+0.2mol·L -1 Magnesium sulfate+0.02mol·L -1 Ammonium dihydrogen phosphate) and electrolyte composition B (2mol L -1 Magnesium nitrate+0.2mol·L -1 Magnesium sulfate+0.04mol·L -1 ammonium molybdate) mixed in a volume ratio of 1:9. The negative electrode material is AZ31B magnesium alloy, the surface adopts a cycle potential range of -1.0~2.0V, the number of scans is 10 times, and the scan speed is 0.03V s -1 The cyclic voltammetry parameter is used to plate polyaniline film, and the electroplating solution is 0.2mol L -1 Aniline+0.5mol·L -1 sodium salicylate. After coating, soak in the electrolyte for 1 day, and then test the surface morphology, impedance value, and discharge performance of the magnesium negative electrode.

Embodiment 3

[0030] The electrolyte solution used in this embodiment is composed of electrolyte solution A (2mol L -1 Magnesium nitrate+0.2mol·L -1 Magnesium sulfate+0.02mol·L -1 Ammonium dihydrogen phosphate) and electrolyte composition B (2mol L -1 Magnesium nitrate+0.2mol·L -1 Magnesium sulfate+0.02mol·L -1 ammonium molybdate) mixed in a volume ratio of 3:7. The negative electrode material is AZ31B magnesium alloy, the surface adopts a cycle potential range of -1 ~ 3V, the number of scans is 10 times, and the scan speed is 0.03V s -1 The cyclic voltammetry parameter is used to plate polyaniline film, and the electroplating solution is 0.2mol L -1 Aniline+0.5mol·L -1 sodium salicylate. After coating, soak in the electrolyte for 1 day, and then test the surface morphology, impedance value, and discharge performance of the magnesium negative electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com