Carbon-coated and Na <+>-doped LiMnPO4 positive electrode material as well as preparation method and application thereof

A positive electrode material, NH4H2PO4 technology, applied in the direction of positive electrode, battery electrode, active material electrode, etc., to achieve the effect of abundant raw material sources, low price, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

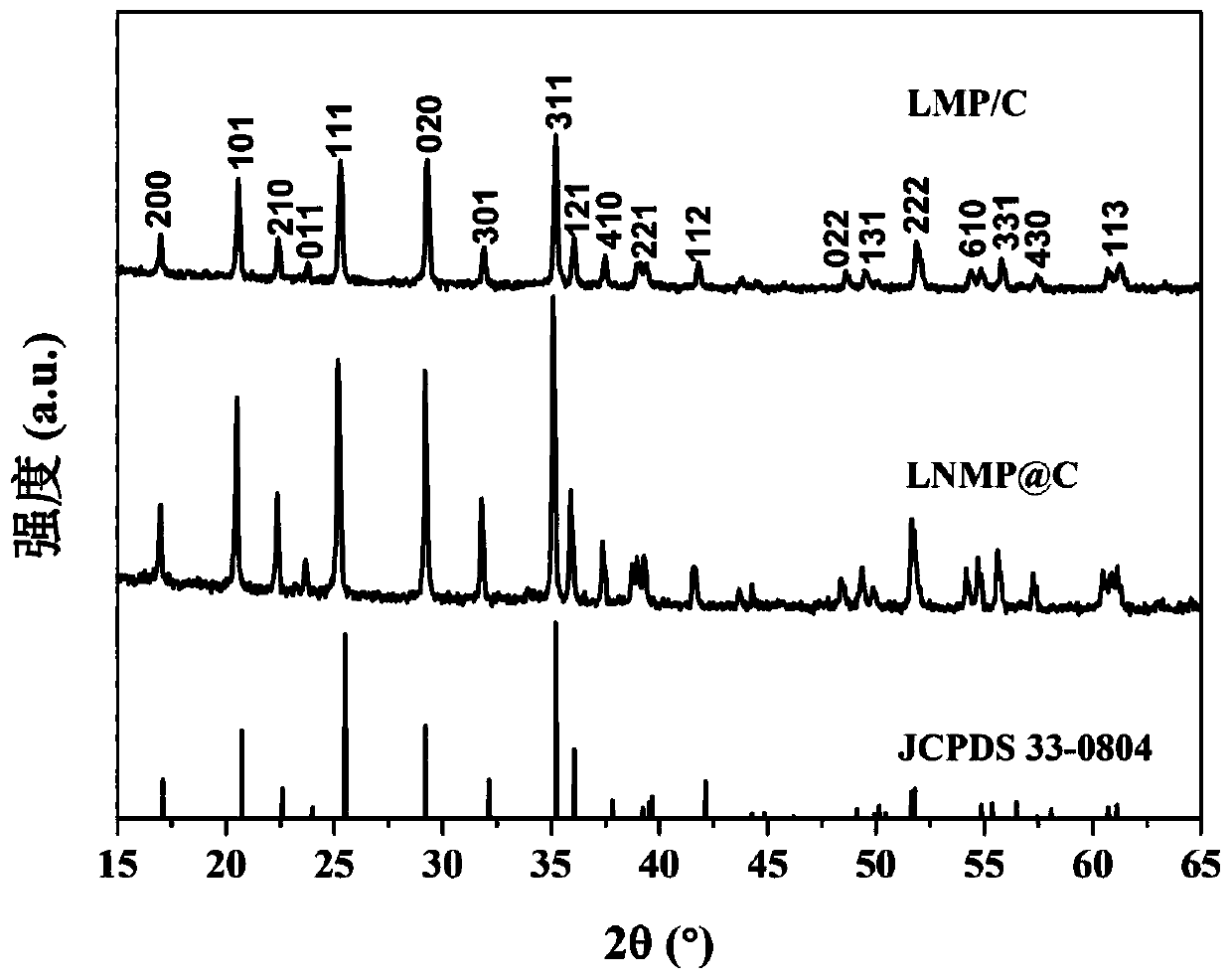

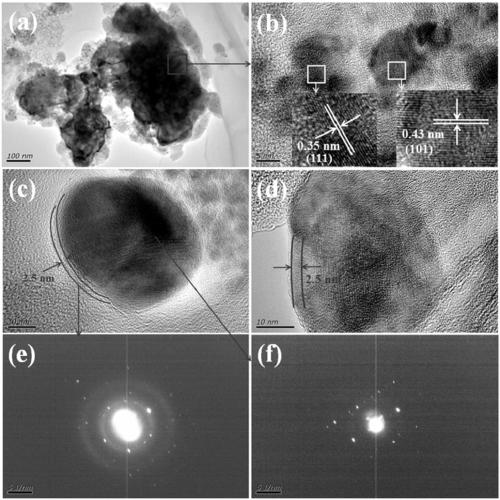

[0037] Weigh Li respectively according to the molar ratio of 1:2:2 2 CO 3 1.4778g, MnCO 3 4.598g, NH 4 h 2 PO 4 4.6008g, according to the product LiMnPO 4 10% of carbon content weighs 1.64g of sodium polyacrylate. Put the above raw materials into a ball milling jar, add absolute ethanol as a dispersant to 1 / 3 of the height of the ball milling jar, and perform ball milling. After ball milling for 6 hours, dry in an oven at 70°C for 8 hours. After grinding evenly, burn at 550°C for 8 hours at a heating rate of 5°C / min in a nitrogen-filled tube furnace to obtain carbon-coated and Na + Doped LiMnPO 4 Cathode material (LNMP@C).

Embodiment 2

[0039] Weigh Li respectively according to the molar ratio of 1:2:2 2 CO 3 1.4778g, MnCO 3 4.598g, NH 4 h 2 PO 4 4.6008g, according to the product LiMnPO 4 5%, 15%, and 20% of the carbon content take by weighing sodium polyacrylate 0.82g, 2.46g, 3.28g respectively, and prepare carbon-coated and Na polyacrylates with different carbon contents in the same manner as in Example 1 + Doped LiMnPO 4 Cathode material (LNMP@C).

Embodiment 3

[0041] As a comparison, select polyacrylic acid as the carbon source, weigh 0.37g, 0.73g, 1.10g, and 1.47g of polyacrylic acid respectively, and prepare different carbon contents (5, 10, 15, 20wt%) according to the same method as in Example 1. Carbon coated LiMnPO 4 Cathode material (LMP / C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com