Non-glutaraldehyde pre-installable dry biological valve material and preparation method and application thereof

A biological valve, glutaraldehyde technology, applied in the direction of tissue regeneration, medical science, prosthesis, etc., can solve the problems of inability to protect elastin, residue of glutaraldehyde aldehyde group, and inability to quickly expand, etc., to achieve good anti-calcification performance and Effects of elastin stability, easy calcification, and avoidance of glutaraldehyde residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

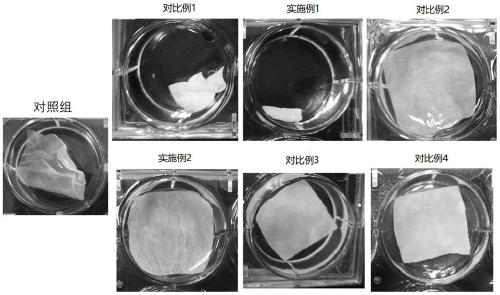

Image

Examples

Embodiment 1

[0034] A preferred embodiment of the present invention provides a method for preparing a non-glutaraldehyde prepackaged dry biological valve material. The specific steps are as follows:

[0035] a. Soak the porcine pericardium in 0.1wt% disodium edetate solution for 1h, then soak in 0.1wt% sodium lauryl sulfate solution for 24h, then rinse in sterile PBS solution for 1h .

[0036] b. Soak the decellularized pericardium material in 5wt% glycidyl methacrylate solution and incubate at 37° C. for 3 days to introduce a carbon-carbon double bond structure.

[0037] c. Soak the material obtained in the above step in a 0.1M aqueous solution of 3-propyl methacrylate and incubate at 37° C. for 24 hours.

[0038] d. Add 20 mM ammonium persulfate and 20 mM sodium bisulfite aqueous solution to the material obtained in the previous step for cross-linking at 37° C. for 24 h.

[0039] e. Using a mixed solution of 60 mM carbodiimide and 12 mM N-hydroxysuccinimide, soak the material obtained ...

Embodiment 2

[0043]A preferred embodiment of the present invention provides a method for preparing a non-glutaraldehyde prepackaged dry biological valve material. The specific steps are as follows:

[0044] a. Soak the porcine pericardium in 0.1wt% disodium edetate solution for 1h, then soak in 0.1wt% sodium lauryl sulfate solution for 24h, then rinse in sterile PBS solution for 1h .

[0045] b. Soak the decellularized pericardium material in 2wt% glycidyl methacrylate solution and incubate at 37° C. for 3 days to introduce a carbon-carbon double bond structure.

[0046] c. Soak the material obtained in the above step in a 0.1M aqueous solution of 3-propyl methacrylate and incubate at 37° C. for 24 hours.

[0047] d. Add 20 mM ammonium persulfate and 20 mM sodium bisulfite aqueous solution to the material obtained in the previous step for cross-linking at 37° C. for 24 h.

[0048] e. Using a mixed solution of 60 mM carbodiimide and 12 mM N-hydroxysuccinimide, soak the material obtained i...

Embodiment 3

[0052] A preferred embodiment of the present invention provides a method for preparing a non-glutaraldehyde prepackaged dry biological valve material. The specific steps are as follows:

[0053] a. Soak the porcine pericardium in 0.2wt% disodium edetate solution for 1h, then soak in 0.2wt% sodium lauryl sulfate solution for 20h, then rinse in sterile PBS solution for 3h .

[0054] b. Soak the decellularized pericardium material in 8wt% glycidyl methacrylate solution and incubate at 37° C. for 4 days to introduce a carbon-carbon double bond structure.

[0055] c. Soak the material obtained in the above step in a 0.2M aqueous solution of 3-propyl methacrylate and incubate at 37° C. for 24 hours.

[0056] d. Add 20 mM ammonium persulfate and 20 mM sodium bisulfite aqueous solution to the material obtained in the previous step for cross-linking at 37° C. for 24 h.

[0057] e. Using a mixed solution of 50 mM carbodiimide and 15 mM N-hydroxysuccinimide, soak the material obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com