Preparation method of high-performance porous photocatalytic ball

A photocatalytic, high-performance technology, applied in the field of photocatalysis, can solve the problems of easy deactivation of photocatalysts, and achieve the effect of solving easy oxidation and easy hydrolysis, improving performance and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

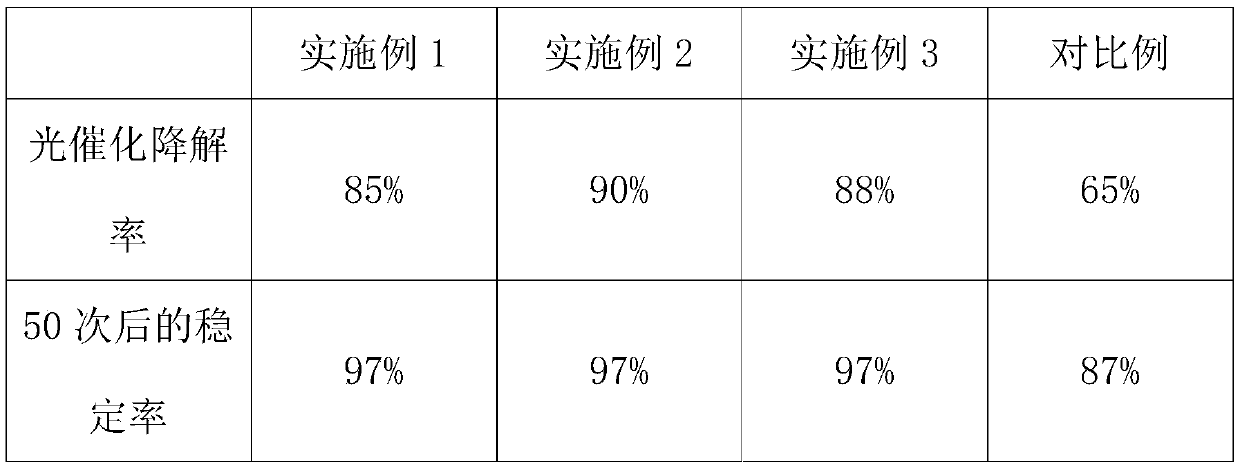

Examples

preparation example Construction

[0016] A method for preparing a high-performance porous photocatalytic sphere, comprising the steps of:

[0017] Step 1, stirring and mixing polyvinylpyrrolidone powder and sodium sulfite powder under a nitrogen environment to form a mixed solid; the stirring speed of stirring and mixing is 500-1500r / min, and the mass ratio of polyvinylpyrrolidone powder and sodium sulfite powder is 3:2-5 ;Polyvinylpyrrolidone and sodium sulfite are physically stirred to form a good mixing effect, and the polyvinylpyrrolidone is evenly dispersed between the sodium sulfite powder to form a good dispersion;

[0018] Step 2, add oxygen-free ethanol to the mixed solid and stir to form a viscous substance with uniform viscosity; the stirring speed is 1000-2000r / min, the temperature is 0-5°C, and the amount of oxygen-free ethanol added is polyethylene 30-50% of the quality of pyrrolidone; oxygen-free ethanol is added in polyvinyl pyrrolidone, polyvinyl pyrrolidone can be dissolved, and the dissolved...

Embodiment 1

[0023] A method for preparing a high-performance porous photocatalytic sphere, comprising the steps of:

[0024] Step 1, stirring and mixing polyvinylpyrrolidone powder and sodium sulfite powder under a nitrogen environment to form a mixed solid; the stirring speed of stirring and mixing is 500r / min, and the mass ratio of polyvinylpyrrolidone powder and sodium sulfite powder is 3:2;

[0025] Step 2, add oxygen-free ethanol to the mixed solids and stir to form a viscous substance with uniform consistency; the stirring speed is 1000r / min, the temperature is 0°C, and the amount of oxygen-free ethanol added is 1 / 2 of the mass of polyvinylpyrrolidone 30%;

[0026] Step 3: put the viscous material into the mold, cure at constant temperature to form prefabricated balls, soak the prefabricated balls in oxygen-free ethanol, take out and dry to form porous balls; constant temperature curing is carried out in nitrogen environment, and the temperature of constant temperature curing is 80°...

Embodiment 2

[0030] A method for preparing a high-performance porous photocatalytic sphere, comprising the steps of:

[0031] Step 1, stirring and mixing polyvinylpyrrolidone powder and sodium sulfite powder under a nitrogen environment to form a mixed solid; the stirring speed of stirring and mixing is 1500r / min, and the mass ratio of polyvinylpyrrolidone powder and sodium sulfite powder is 3:5;

[0032] Step 2, add oxygen-free ethanol to the mixed solids and stir to form a viscous substance with uniform consistency; the stirring speed is 2000r / min, the temperature is 5°C, and the amount of oxygen-free ethanol added is 1 / 4 of the quality of polyvinylpyrrolidone 50%;

[0033] Step 3, put the viscous material into the mold, solidify at a constant temperature to form a prefabricated ball, soak the prefabricated ball in oxygen-free ethanol, take it out and dry it to form a porous ball; the constant temperature curing is carried out in an argon environment, and the temperature of the constant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com