Waste biomass resource utilization and harmless treatment method

A technology of harmless treatment and waste biomass, applied in chemical instruments and methods, biofuels, solid waste removal, etc., can solve the problems of metal cyanide pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

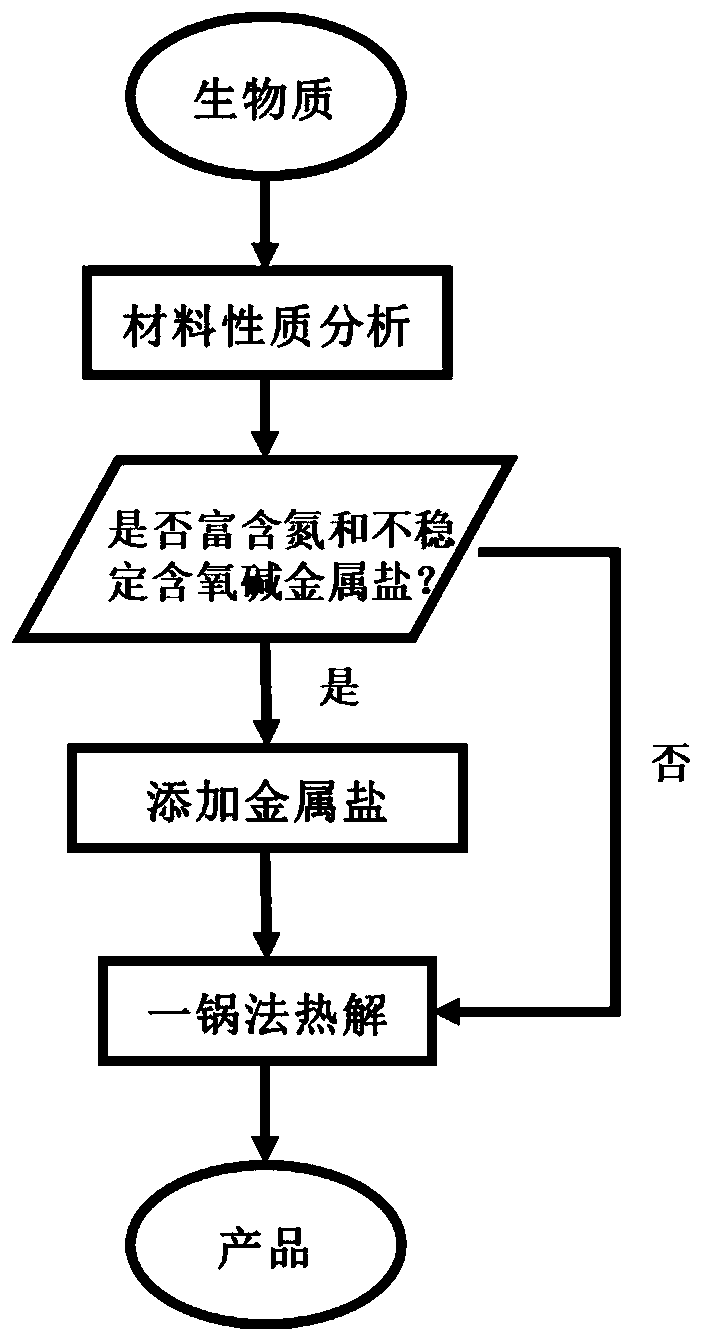

Method used

Image

Examples

Embodiment 1

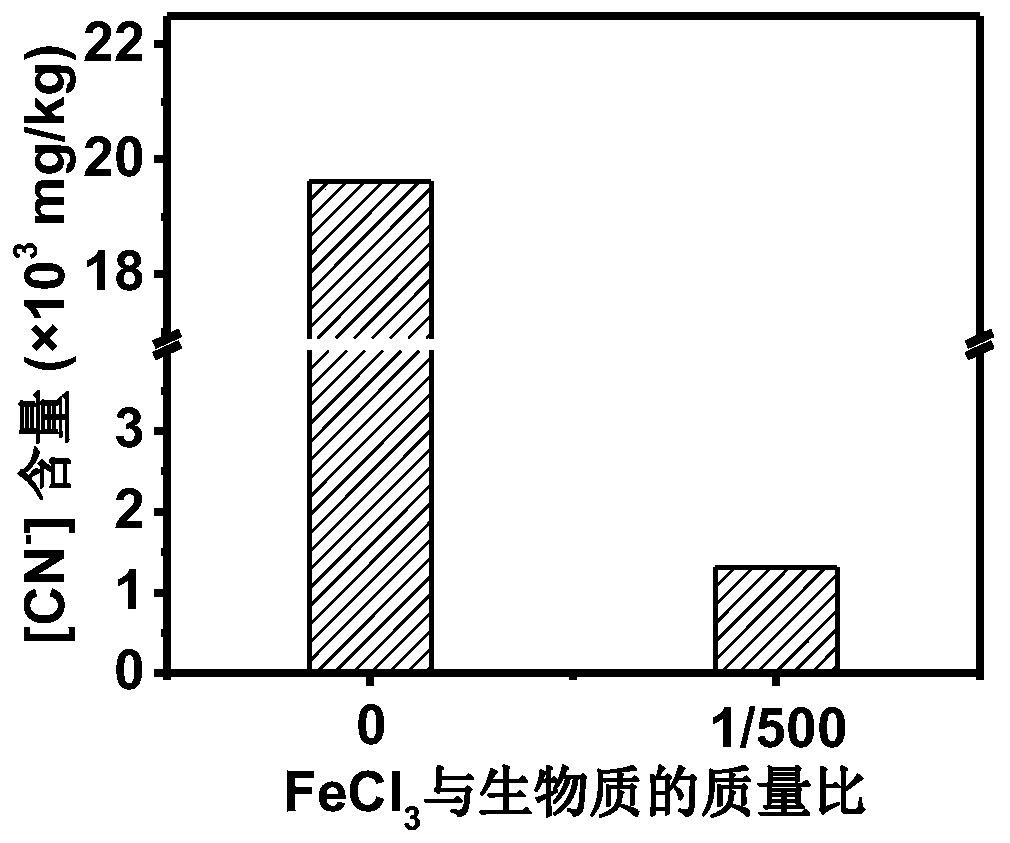

[0023] Wheat protein, K 2 CO 3 and FeCl 3 According to a certain mass ratio, wheat protein and K 2 CO 3 The mass ratio of wheat protein to FeCl is 1:10 3 The mass ratio of the mixture is 1:500, mixed with water, and shaken for 12 hours; the mixture is dried and placed in a porcelain boat, placed in a tube furnace, and the flow rate is 0.1 L / min in N 2 Under the atmosphere, the temperature was raised to 800 °C at a rate of 5 °C / min, and maintained for 1 hour, and cooled to room temperature after the reaction was completed. Put the obtained biochar in a glass tube, add an appropriate amount of NaOH solution for extraction, filter and dilute to an appropriate concentration, and use ion chromatography to determine CN - content. low concentration of FeCl 3 It can effectively control the content of metal cyanide in biochar.

Embodiment 2

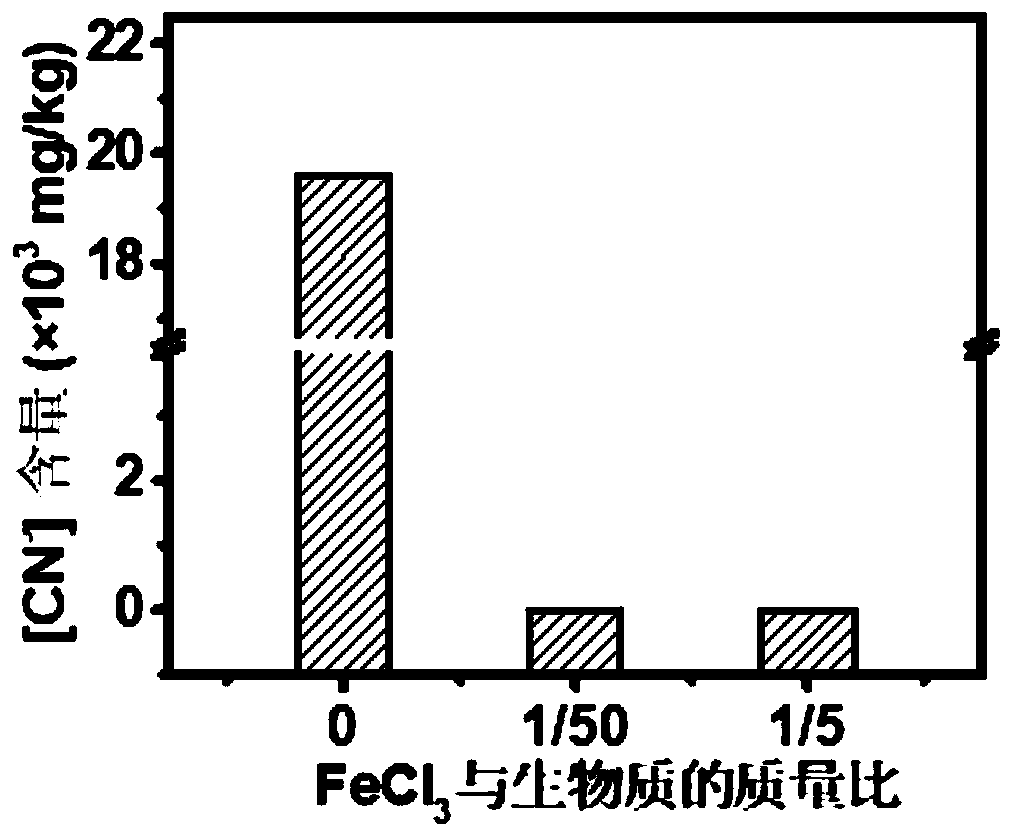

[0025] Wheat protein, K 2 CO 3 and FeCl 3 According to a certain mass ratio, wheat protein and K 2 CO 3 The mass ratio of wheat protein to FeCl is 1:10 3 The mass ratio is 1:50 and 1:5, mixed with water, shaken for 12 hours; the mixture is dried and placed in a porcelain boat, placed in a tube furnace, under the flow rate of 0.1 L / min N 2 Under the atmosphere, the temperature was raised to 800 °C at a rate of 5 °C / min, and maintained for 1 hour, and cooled to room temperature after the reaction was completed. Put the obtained biochar in a glass tube, add an appropriate amount of NaOH solution for extraction, filter and dilute to an appropriate concentration, and use ion chromatography to determine CN - content. High concentration of FeCl 3 It can effectively and completely inhibit the formation of metal cyanide in biochar.

Embodiment 3

[0027] Wheat protein, K 2 CO 3 and MgCl 2 According to a certain mass ratio, wheat protein and K 2 CO 3 The mass ratio of wheat protein to MgCl is 1:10 2 The mass ratio of the mixture is 1:50, mixed with water, and shaken for 12 hours; the mixture is dried and placed in a porcelain boat, placed in a tube furnace, and the flow rate is 0.1 L / min in N 2 Under the atmosphere, the temperature was raised to 800 °C at a rate of 5 °C / min, and maintained for 1 hour, and cooled to room temperature after the reaction was completed. Put the obtained biochar in a glass tube, add an appropriate amount of NaOH solution for extraction, filter and dilute to an appropriate concentration, and use ion chromatography to determine CN - content. MgCl 2 It can effectively inhibit the formation of metal cyanide in biochar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com