Ultrathin hydrotalcite-based composite photoelectrode and application thereof in coupling of photoelectrolysis of water and organic matter oxidation reaction

A talc-based, composite light technology, applied in electrolytic organic production, electrodes, electrolytic components, etc., can solve problems that have not received enough attention, and achieve improved overall energy efficiency and molecular reaction efficiency, high atom economy, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

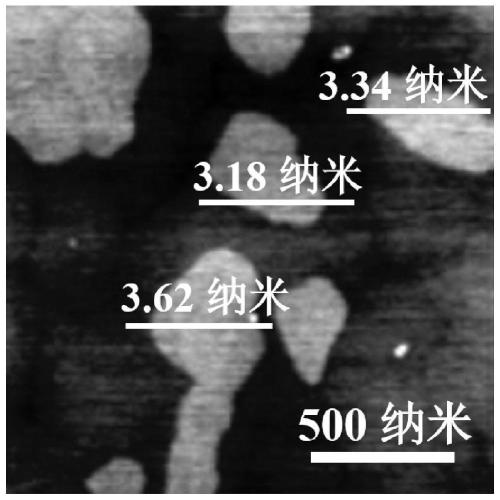

[0027] A. Weigh 0.306g Co(NO3 ) 2 ·6H 2 O, 0.132g Al(NO 3 ) 3 9H 2 O, 0.424g urea, 0.07g NH 4 F. In a 250mL beaker, add 70mL deionized water, mix well, then add 1mL graphene water dispersion with a concentration of 1mg / mL, ultrasonically stir until a uniform solution is formed, ultrasonic power 50W, time 10min, temperature 20°C .

[0028] B. BiVO 4 The conductive surface of the electrode is tilted upwards by 45°, put it into the liner of the hydrothermal kettle, and add 4mL of the solution prepared in step A and 3mL of acetone (mass fraction ≥ 99.9%), so that the growth of BiVO 4 The part of the electrode is completely submerged in the solution, the ultrasonic power is 50W, the time is 5min, fully mixed, and the hydrothermal reaction is carried out at 100°C for 4h. After washing with water, dry in an oven at 60°C for 1 hour to obtain G@U-LDHs / BiVO 4 photoelectrode.

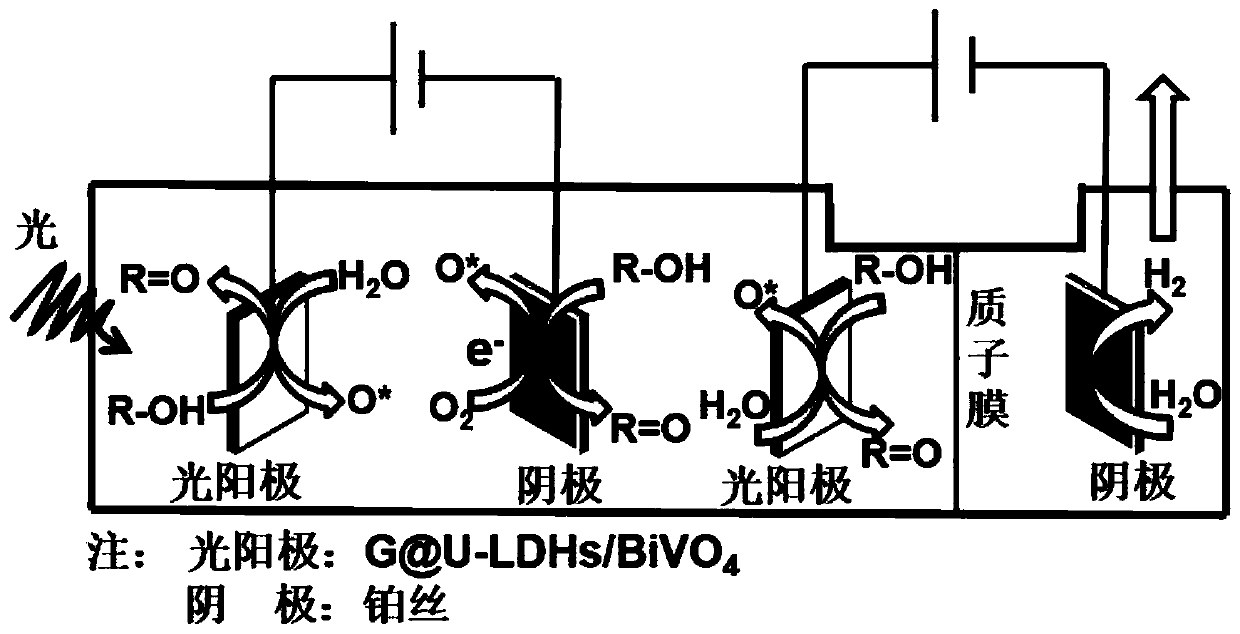

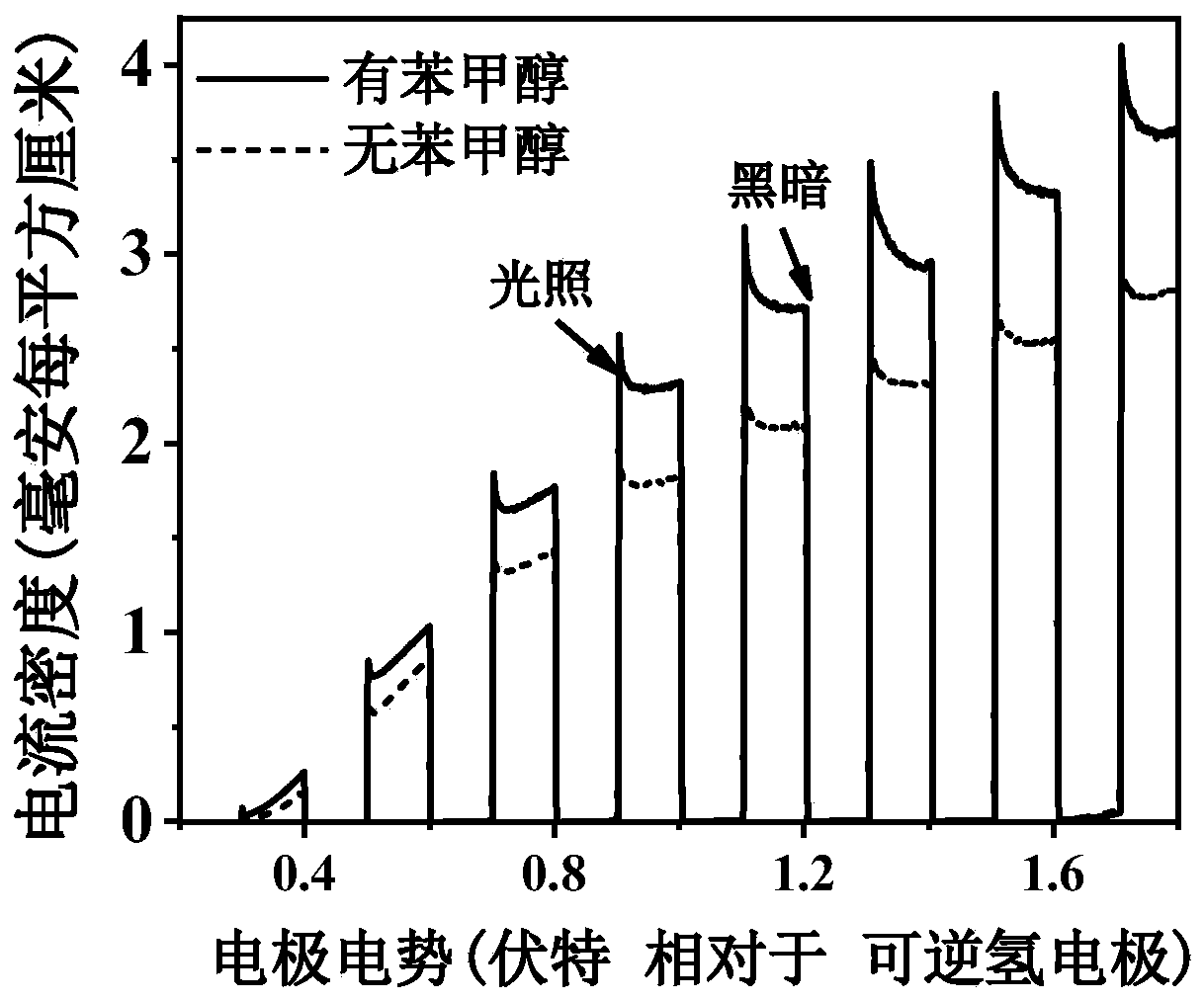

[0029] C. At room temperature, measure 8 mL of phosphate buffer solution (pH=7, 0.1 mol / L) in a closed...

Embodiment 2

[0034] A. Weigh 0.343g Ni(NO 3 ) 2 ·6H 2 O, 0.135g Al(NO 3 ) 3 9H 2 O, 0.435g urea, 0.07g NH 4 F. In a 250mL beaker, add 70mL deionized water, mix evenly, then add 1mL graphene water dispersion with a concentration of 1mg / mL, ultrasonically stir until mixed to form a uniform solution, ultrasonic power 50W, time 10min, temperature 20 ℃.

[0035] B. BiVO 4 The conductive surface of the electrode is tilted upwards by 45°, put it into the liner of the hydrothermal kettle, and add 4mL of the solution prepared in step A and 3mL of acetone (mass fraction ≥ 99.9%), so that the growth of BiVO 4 The part of the electrode is completely submerged in the solution, the ultrasonic power is 50W, the time is 5min, fully mixed, and the hydrothermal reaction is carried out at 100°C for 4h. After washing with water, dry in an oven at 60°C for 1 hour to obtain G@U-LDHs composite BiVO 4 photoelectrode.

[0036] C. At room temperature, measure 8 mL of phosphate buffer solution (pH=7, 0.1 m...

Embodiment 3

[0040] A. Weigh 0.446g Zn(NO 3 ) 2 ·6H 2 O, 0.134g Al(NO 3 ) 3 9H 2 O, 0.426g urea, 0.068g NH 4 F. In a 250mL beaker, add 70mL deionized water, mix evenly, then add 1mL graphene dispersion with a concentration of 1mg / mL, ultrasonically stir until a uniform solution is formed, ultrasonic power 50W, time 10min, temperature 20°C .

[0041] B. BiVO 4 The conductive surface of the electrode is tilted upwards by 45°, put it into the liner of the hydrothermal kettle, and add 4mL of the solution prepared in step A and 3mL of acetone (mass fraction ≥ 99.9%), so that the growth of BiVO 4 The part of the electrode is completely submerged in the solution, the ultrasonic power is 50W, the time is 5min, fully mixed, and the hydrothermal reaction is carried out at 100°C for 4h. After washing with water, dry in an oven at 60°C for 1 hour to obtain G@U-LDHs composite BiVO 4 photoelectrode.

[0042] C. At room temperature, measure 8 mL of phosphate buffer solution (pH=7, 0.1 mol / L) in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com