Design method of plasma sensor and sensor prepared by design method

A plasma and design method technology, which is applied in nanotechnology, instruments, scientific instruments and other directions for sensing, can solve the problems of complex manufacturing process, difficult precision control, and cannot be reused, and achieves high parameter control precision and high Sensitivity and ease of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

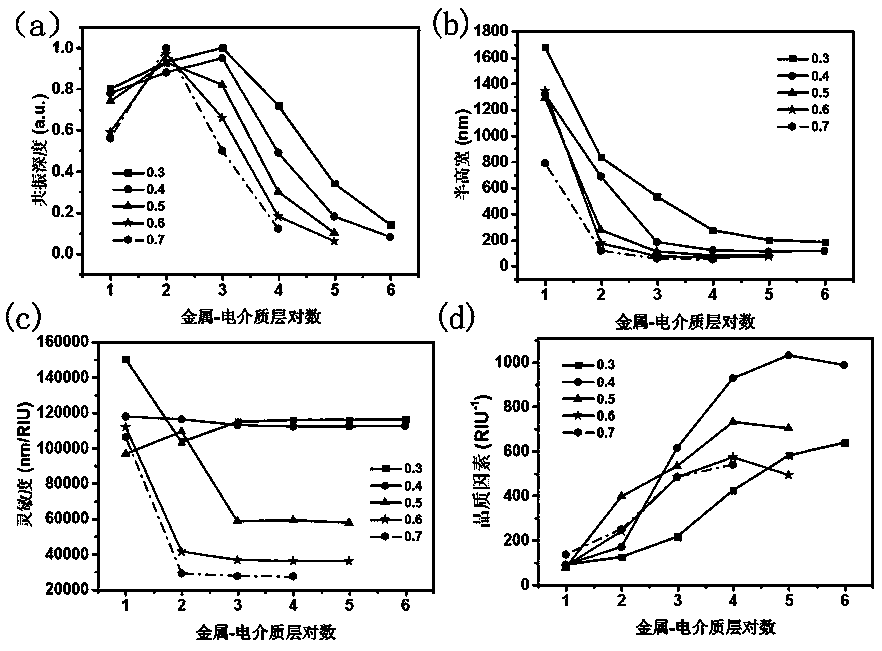

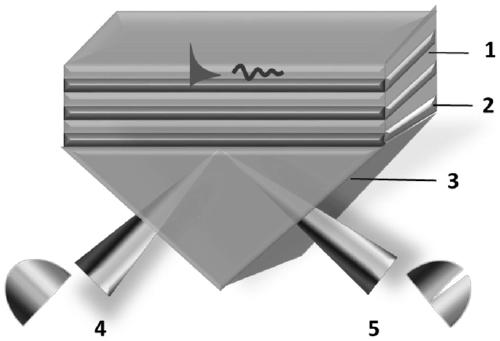

[0050] This embodiment provides a design method of a plasmonic sensor. Firstly, the metal filling ratio ρ of the hyperbolic metamaterial and the logarithm N of the metal-dielectric layer are obtained by software simulation calculation. bi The optimal combination parameters of the hyperbolic metamaterials are combined with the multilayer film structure of the optimal combination parameters and the Kretschmann structure to make a plasmon sensor. The sensor is a Kretschmann structure plasmon sensor based on the hyperbolic metamaterial dispersion engineering . Specifically, the metal in this embodiment is selected as Ag, and the dielectric is TiO 2 ,like figure 1 Shown is the principle structure diagram of the Kretschmann structure plasmon sensor based on hyperbolic metamaterial dispersion engineering in this embodiment, wherein the serial numbers represent: 1, titanium dioxide; 2, silver; 3, prism; 4, incident light; 5, outgoing light.

[0051] Furthermore, the simulation proc...

Embodiment 2

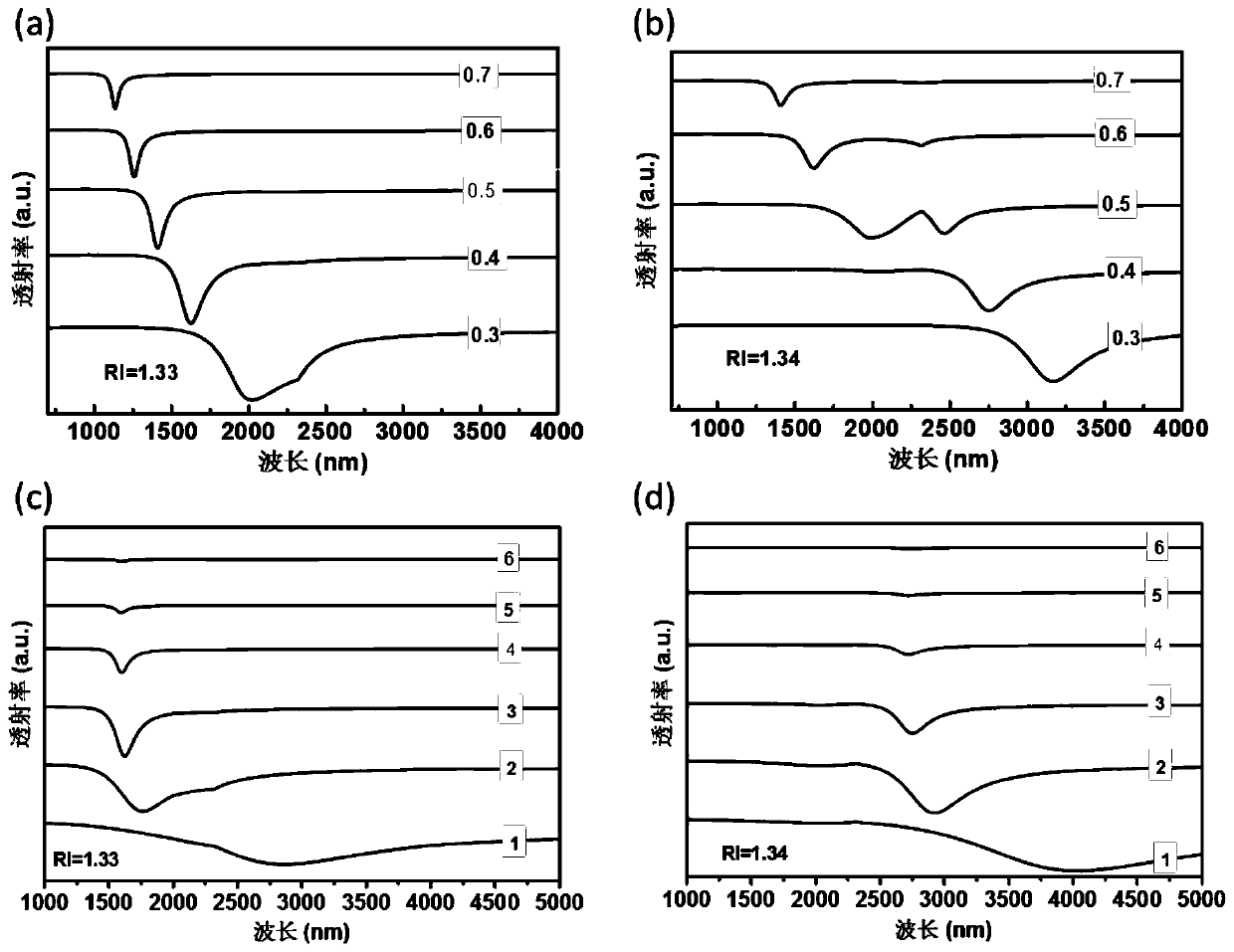

[0064] In the design method of a plasmonic sensor provided in this embodiment, the metal filling ratio ρ of the hyperbolic metamaterial and the logarithm N of the metal-dielectric layer are calculated first. bi The optimal combination parameters of the hyperbolic metamaterials are combined with the multilayer film structure of the optimal combination parameters and the polishing surface of the side-polished optical fiber to make a plasmonic sensor. The obtained sensor is based on the hyperbolic metamaterial dispersion The side polished fiber optic plasma sensor of the project, its principle and cross-sectional diagram are as follows Figure 5 shown.

[0065] Further, the simulation process uses the finite element method, and uses the quality factor FOM as a reference value to optimize the simulation to obtain the best hyperbolic metamaterial parameter combination. The sensor is a side-polished optical fiber based on hyperbolic metamaterial dispersion engineering. Structured p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com