Rapid analysis and compounding regulation and control methods for components of building spoil

A technology for building spoil and analysis methods, which is applied in the fields of analyzing materials, using wave/particle radiation for material analysis, measuring devices, etc., can solve the problems of less application of XRF method, detection accuracy depends on sample representativeness and digestion completeness, etc. Achieve the effect of improving detection efficiency, superior light-weight thermal insulation performance, and high sintering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

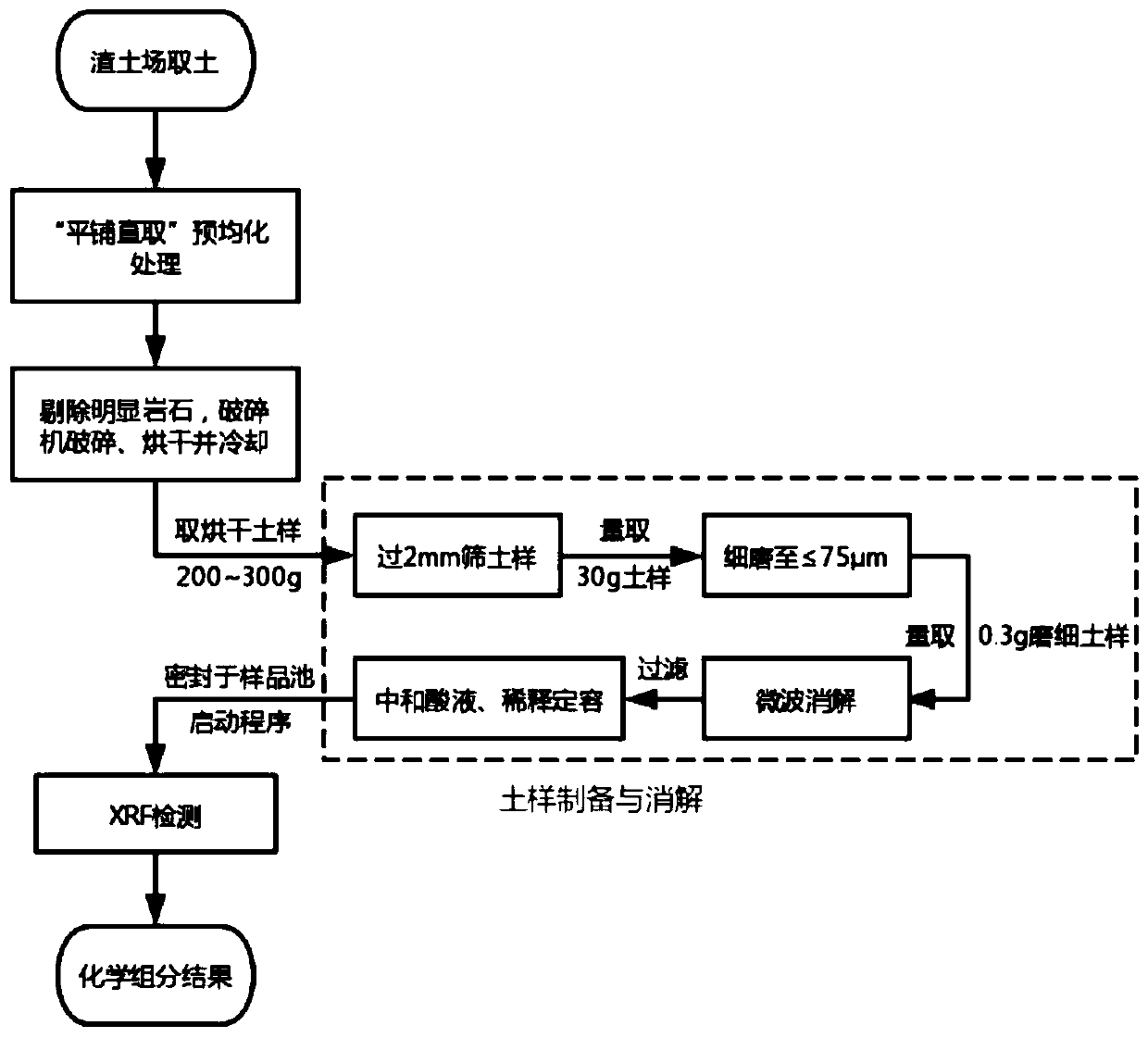

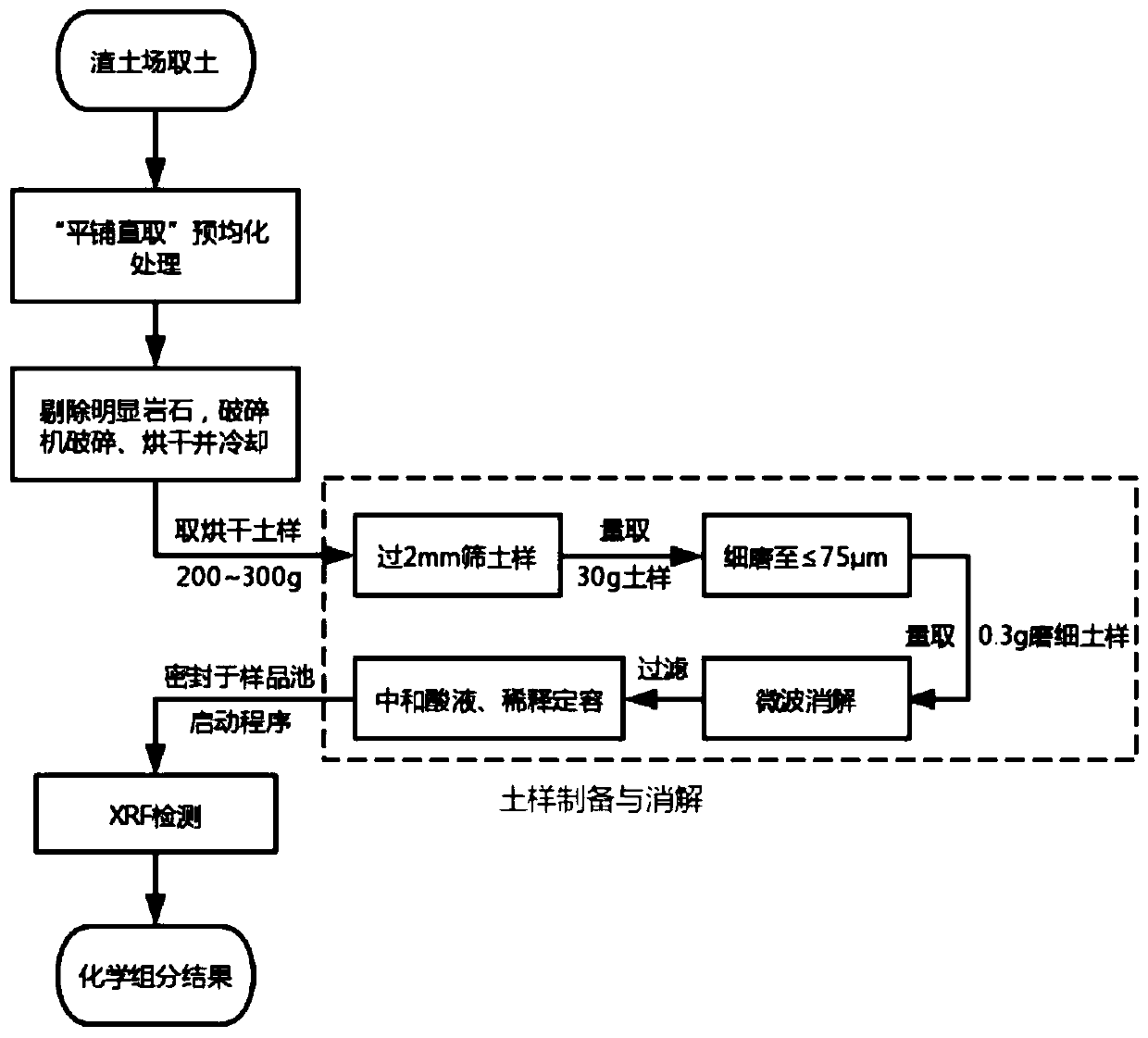

Method used

Image

Examples

Embodiment 1

[0096] According to the above-mentioned rapid analysis method of chemical composition, X-ray fluorescence method was used to analyze the chemical composition of three kinds of construction spoils respectively, and the test results are shown in Table 2:

[0097] Table 2 Chemical composition distribution table of spoil

[0098]

Embodiment 2

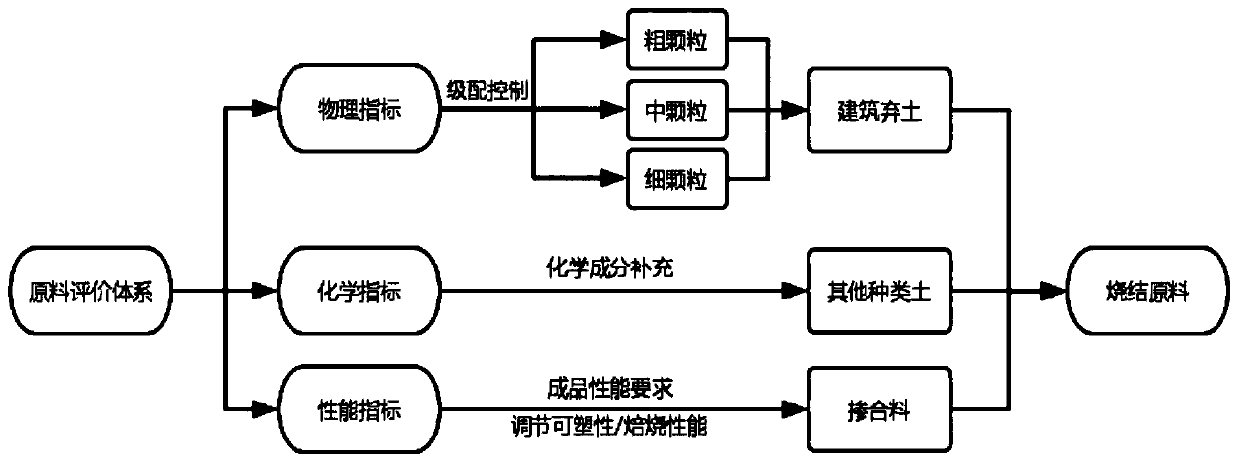

[0100] This embodiment evaluates the No. 1 construction spoil in Table 2, and the evaluation results are as follows: due to the SiO in the construction spoil 2 too low, so doped with SiO 2 Diatomite as the main component supplements the silicon element in the spoil. At the same time, the drying sensitivity coefficient of the raw material is relatively large. Adding an appropriate amount of fly ash can significantly reduce the drying shrinkage during sintering. In addition, adding a small amount of ceramic glaze residue can reduce the harmful component SO in raw materials 3 Frost damage caused by excessive content.

Embodiment 3

[0102] This embodiment evaluates the No. 2 construction spoil in Table 2, and the evaluation results are as follows: Due to the Al in the construction spoil composition 2 o 3 The content is too low, so kaolin with relatively high aluminum content is added to supplement the aluminum element to meet the needs of the solid-phase reaction of raw materials; coal gangue is added as a raw material barren agent to reduce the plasticity and dry sensitivity of the spoil and improve the resistance of the finished bricks. folding strength. In addition, adding a small amount of sawdust can even out the heat source during roasting and improve fuel utilization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com