A kind of spherical colloidal crystal microcavity and preparation method thereof

A colloidal crystal, spherical technology, applied in the field of optoelectronics, to achieve high quality factor resonance, high uniformity, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

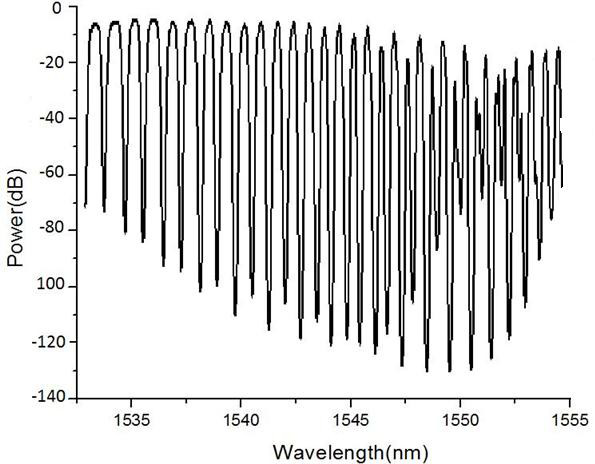

[0039] The invention provides a spherical colloidal crystal microcavity and a preparation method thereof, which can obtain a spherical microcavity with a high quality factor. The preparation method of the spherical colloidal crystal microcavity mainly includes the following steps:

[0040] S1. Make one end of the optical fiber spherical by arc discharge

[0041] S101. Cut off a section of single-mode optical fiber, remove the resin coating (3~5cm) from one end of the optical fiber with fiber pliers, wipe the optical fiber with a dust-free paper glued with alcohol, and then cut the optical fiber with an optical fiber cutter to make it clean and free of resin Coated and flat ends;

[0042] S102. Using the manual mode of the optical fiber fusion welding machine, put the flat end of the optical fiber into the slot for optical fiber fusion, and discharge the electrodes of the optical fiber fusion splicer to generate an arc. The number of discharges is 3 to 8 times, and the time in...

Embodiment 1

[0053] The preparation method of the spherical colloidal crystal microcavity mainly comprises the following steps:

[0054] S1. Make one end of the optical fiber spherical by arc discharge

[0055] S101. Cut off a section of single-mode optical fiber, remove the resin coating from one end of the optical fiber with fiber optic pliers, wipe the optical fiber with a dust-free paper stuck to alcohol, and then cut the optical fiber with an optical fiber cutter to make it clean, free of resin coating and flat on the end surface status.

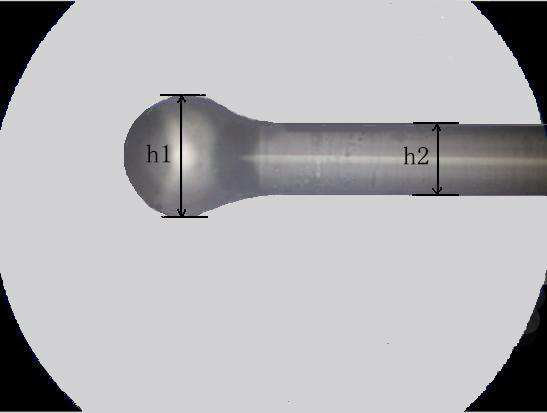

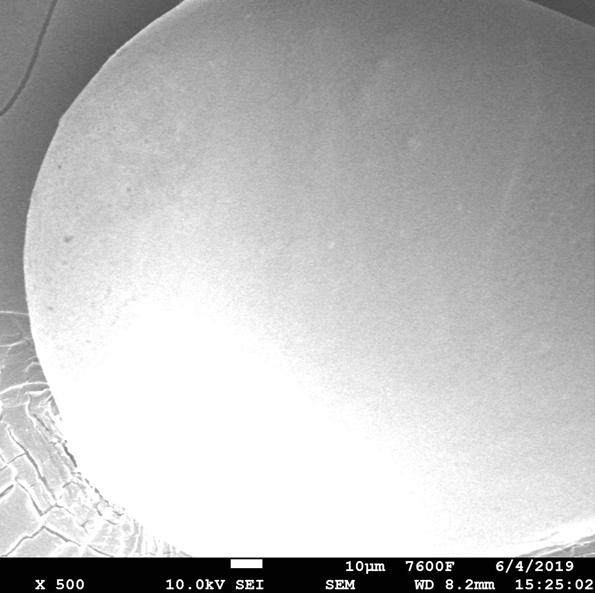

[0056] S102. Using the manual mode of the optical fiber fusion welding machine, put the flat end of the optical fiber into the slot for optical fiber fusion, so that the electrodes of the optical fiber fusion splicer discharge to generate an arc. The number of discharges is 4 times, and the time interval between each discharge is about 10s. That is, a spherical optical fiber at one end was obtained, the diameter h1 of the spherical shape was 212.42...

Embodiment 2

[0066] The preparation method of the spherical colloidal crystal microcavity mainly comprises the following steps:

[0067] S1. Make one end of the optical fiber spherical by arc discharge

[0068] S101. Cut off a section of single-mode optical fiber, remove the resin coating from one end of the optical fiber with fiber optic pliers, wipe the optical fiber with a dust-free paper stuck to alcohol, and then cut the optical fiber with an optical fiber cutter to make it clean, free of resin coating and flat on the end surface status.

[0069] S102. Using the manual mode of the optical fiber fusion welding machine, put the flat end of the optical fiber into the slot for optical fiber fusion, and discharge the electrodes of the optical fiber fusion splicer to generate an arc. The number of discharges is 5 times, and the time interval between each discharge is about 10s. That is, a spherical optical fiber at one end was obtained, the diameter h1 of the spherical shape was 227.85 μm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com