Diaphragm with self-crosslinking effect and preparation method thereof

A self-crosslinking, diaphragm technology, applied in nanotechnology, structural parts, electrical components, etc. for materials and surface science, can solve the problems of poor liquid retention, weak bonding, low heat resistance of the diaphragm, etc. Strong liquid retention ability, improving high temperature shrinkage resistance and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

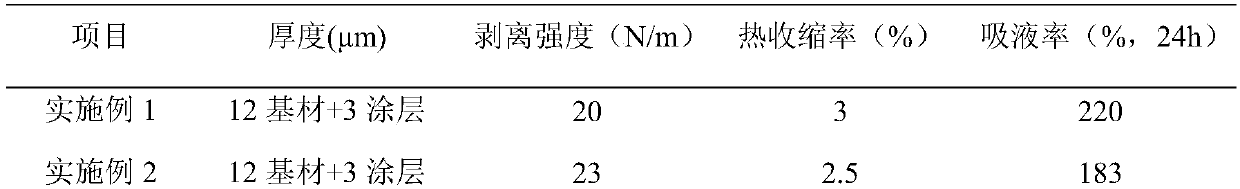

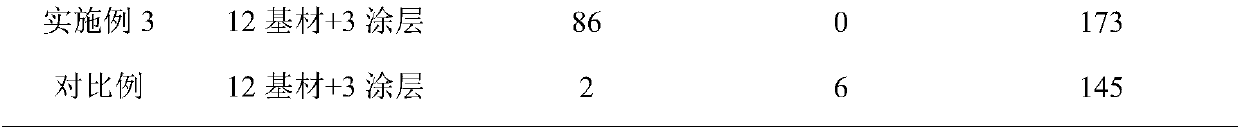

Examples

preparation example Construction

[0019] Correspondingly, an embodiment of the present invention provides a method for preparing an aqueous composition, comprising the following steps:

[0020] S01. Mix the organic solvent and water to form a first mixed solution, and adjust the first mixed solution to pH 4.0-5.0;

[0021] S02. Adding a silane coupling agent and silicon dioxide particles to the first mixed liquid, stirring and mixing, and drying to obtain modified nanometer silicon dioxide particles;

[0022] S03. Dissolving the modified silicon dioxide particles with water to obtain a modified nano silicon dioxide solution;

[0023] S04. Adding methyl methacrylate monomer and potassium persulfate to the modified nano-silica solution, and mixing them under an inert gas to obtain an aqueous composition.

[0024] Specifically, in the above step S01, the organic solvent and water are mixed uniformly to form the first mixed solution. Preferably, the organic solvent includes but not limited to solutions such as is...

Embodiment 1

[0043] Preparation method of diaphragm coating material with self-crosslinking effect:

[0044] 1) Configure the nano-silica dispersion. Mix 100 parts of isopropanol and 5 parts of water evenly to control the pH at 5, slowly add 10 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane (KH -560), stir evenly;

[0045] 2) 20 parts of nano-silica particles, D 50 The value is 300nm, added to the above mixed solution, stirred at 50° C. for 2 hours, and dried to obtain modified nano-silica particles.

[0046] 3) Add 5 parts of modified nano-silica particles to 100 parts of deionized water, add 1 part of methyl methacrylate, and mix well. The temperature was raised to 70°C under nitrogen gas, potassium persulfate was added, and the reaction was carried out at constant temperature for 3 hours.

[0047] 4) Add 10 parts of alcohol ester twelve to the above composition and stir evenly to obtain the final composition.

[0048] The above composition was coated on the surface of the biax...

Embodiment 2

[0050] Preparation method of diaphragm coating material with self-crosslinking effect:

[0051] 1) Configure the nano-silica dispersion. Mix 100 parts of isopropanol and 3 parts of water evenly and control the pH at 5, slowly add quantitatively 8 parts of KH-560 into the mixture, and stir evenly;

[0052] 2) 20 parts of nano-silica particles, D50 The value is 500nm, added to the above mixed solution, stirred at 50° C. for 2 hours, and dried to obtain modified nano-silica particles.

[0053] 3) Add 15 parts of modified nano-silica particles to 100 parts of deionized water, add 3 parts of methyl methacrylate, and mix well. The temperature was raised to 70°C under nitrogen gas, potassium persulfate was added, and the reaction was carried out at constant temperature for 3 hours.

[0054] 4) Add 12 parts of alcohol ester twelve to the above composition and stir evenly to obtain the final composition.

[0055] The above composition was coated on the surface of the biaxially orien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com