A kind of spherical oxide alloy electrode material and preparation method thereof

An alloy electrode, alloying technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reducing product service life, precipitation of metallic lithium, dendrite short circuit, etc., to prolong cycle life, improve electronic conductivity, and improve Effects of Tapped and Compacted Density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method of a spherical oxide alloy electrode material, comprising the following steps:

[0038] (1) Put the lithium source, titanium dioxide, M metal ion source and medium solution in the reaction kettle, and disperse to obtain the precursor;

[0039] (2) Grinding the precursor obtained in step (1) to obtain a uniformly dispersed nanoscale precursor;

[0040] (3) spraying and granulating the nano-precursor obtained in step (2) to obtain a dry spherical precursor;

[0041] (4) Place the dry spherical precursor obtained in step (3) in an air or inert gas atmosphere for pre-sintering and re-sintering, the temperature of the pre-sintering is 450~600°C, and the time of pre-sintering is 5~10h , the re-sintering temperature is 700-850° C., the re-sintering time is 10-16 hours, cooled to room temperature, and obtained.

[0042] In the present invention, unless otherwise specified, the raw materials used are commercially availab...

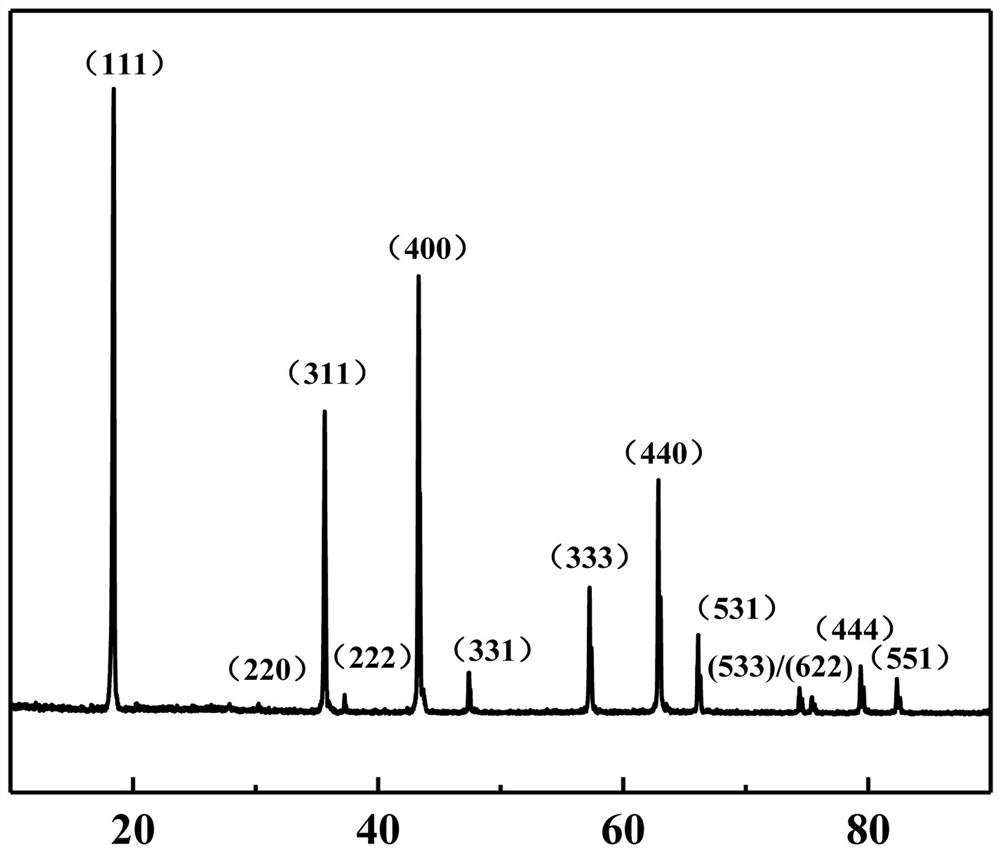

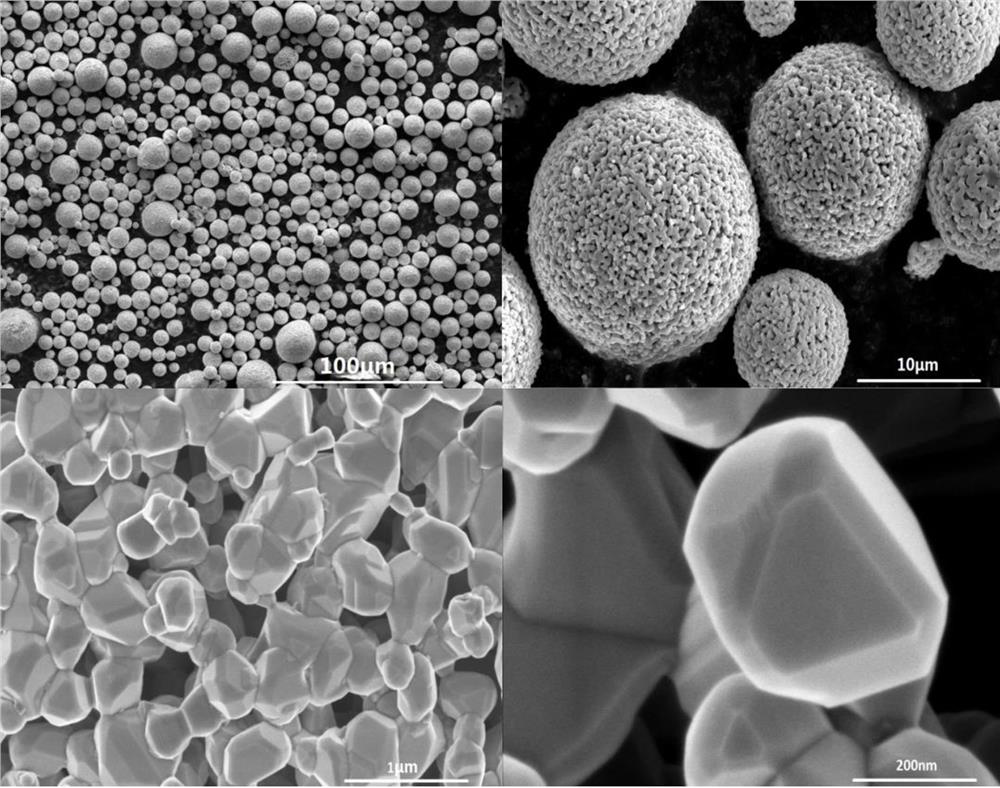

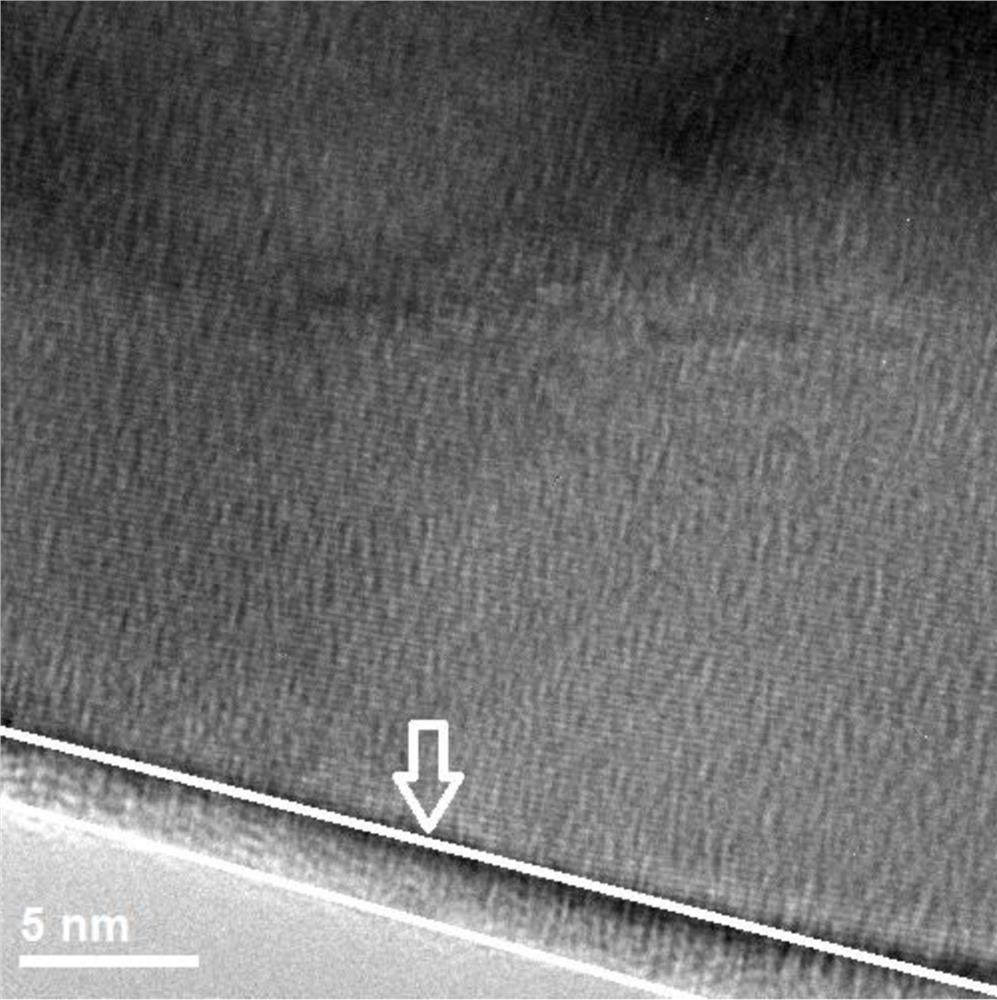

Embodiment 1

[0057] Material ratio: the metal ion is Mg, the molar ratio of titanium ions to metal ions is 5:0.2, and the molar ratio of lithium ions to titanium ions is 4:5.

[0058] (1) Put lithium hydroxide monohydrate, titanium dioxide, nano-magnesium oxide and ethanol solution in the reaction kettle according to the above ratio, the solid-to-liquid ratio is 1:2, keep stirring and ultrasonically dispersing for 4 hours, the speed is 200r / min, get the precursor.

[0059] (2) Place the precursor obtained in step (1) in a high-energy ball mill for high-intensity ball milling at a speed of 1500r / min until the D50 is 0.5 μm to obtain a uniformly dispersed nano precursor.

[0060] (3) Spray and granulate the nano-precursor obtained in step (2), the air inlet temperature is 200°C, the outlet air temperature is controlled at 100°C, and the rotation speed is 20,000r / min to obtain a dry spherical precursor with a D50 of 0.5 μm. The particles are aggregated into secondary spherical particles with...

Embodiment 2

[0063] Material ratio: metal ions are Zn and Ag, the molar ratio of the two metal ions satisfies Zn:Ag =1:1, the molar ratio of titanium ions and the above two metal ions is 5:0.18, the molar ratio of lithium ions and titanium ions The ratio is 4.2:5.

[0064] (1) Put the lithium source, titanium dioxide, zinc acetate, silver nitrate and ethanol solution in the reaction kettle according to the above ratio, the solid-to-liquid ratio is 1:3, keep stirring and ultrasonically dispersing for 4.5h, the speed is 200r / min, get the precursor.

[0065] (2) Place the precursor obtained in step (1) in a high-energy ball mill for high-intensity ball milling for 5 hours at a rotational speed of 1500r / min until the D50 is 0.5 μm to obtain a uniformly dispersed nano-precursor.

[0066] (3) Spray and granulate the nano-precursor obtained in step (2). The air inlet temperature is 200°C, the outlet air temperature is controlled at 85°C, and the rotation speed is 20,000r / min to obtain a dry sphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com