Carbon nitride loaded Pd-based catalyst as well as preparation method and application thereof

A carbon nitride and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as easy to produce attachments, limited catalyst output, and affect catalyst preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a kind of preparation method of the Pd-based catalyst supported by carbon nitride, comprising the following steps:

[0035] A) pyrolyzing thiocyanic acid under a protective gas atmosphere to obtain a thin layer of carbon nitride;

[0036] The temperature of the pyrolysis is 500-650°C; the time of the pyrolysis is 60-120min;

[0037]B) dispersing the thin layer of carbon nitride in water to obtain a first suspension;

[0038] C) adding the Pd precursor to the first suspension and stirring to obtain a second suspension;

[0039] D) adding sodium hydroxide to the second suspension, adjusting the pH to 10-12, and stirring for 10-40 minutes to obtain the third suspension;

[0040] E) Add sodium borohydride to the third suspension, stir to obtain the fourth suspension, continue stirring for 4 to 8 hours, separate the fourth suspension from solid to liquid, and dry the obtained solid to obtain carbon nitride Supported Pd-based catalysts.

[0041] In ...

Embodiment 1

[0065] Put 2g of thiocyanuric acid in a corundum boat with a cover, put the corundum boat in a muffle furnace, and pyrolyze it at 600°C for 1h under a nitrogen atmosphere to obtain a thin-layer carbon nitride support;

[0066] Add 95mg of thin-layer carbon nitride carrier to 90ml of deionized water, and disperse evenly by ultrasonic to obtain a homogeneous suspension 1;

[0067] 0.85mlH 2 PdCl 4 The solution (5.9mg / ml) was added to the suspension 1 to obtain the suspension 2, which was stirred for 2h;

[0068] Adjust the pH of the solution to 10.8 with a freshly prepared 1mol / L NaOH solution to obtain a homogeneous suspension 3;

[0069]Add 5ml of sodium borohydride solution (1mg / ml) into the above suspension 3, and keep it at room temperature for more than 4h to obtain suspension 4, which is suction filtered, washed with water, and dried to obtain Pd with uniform particle size. Nano-catalyst (denoted as Pd / C 3 N 4 -S-10.8).

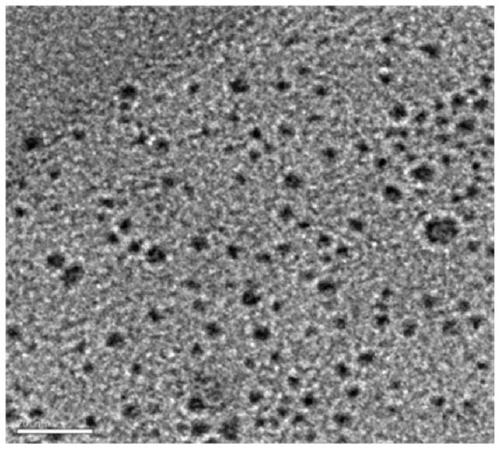

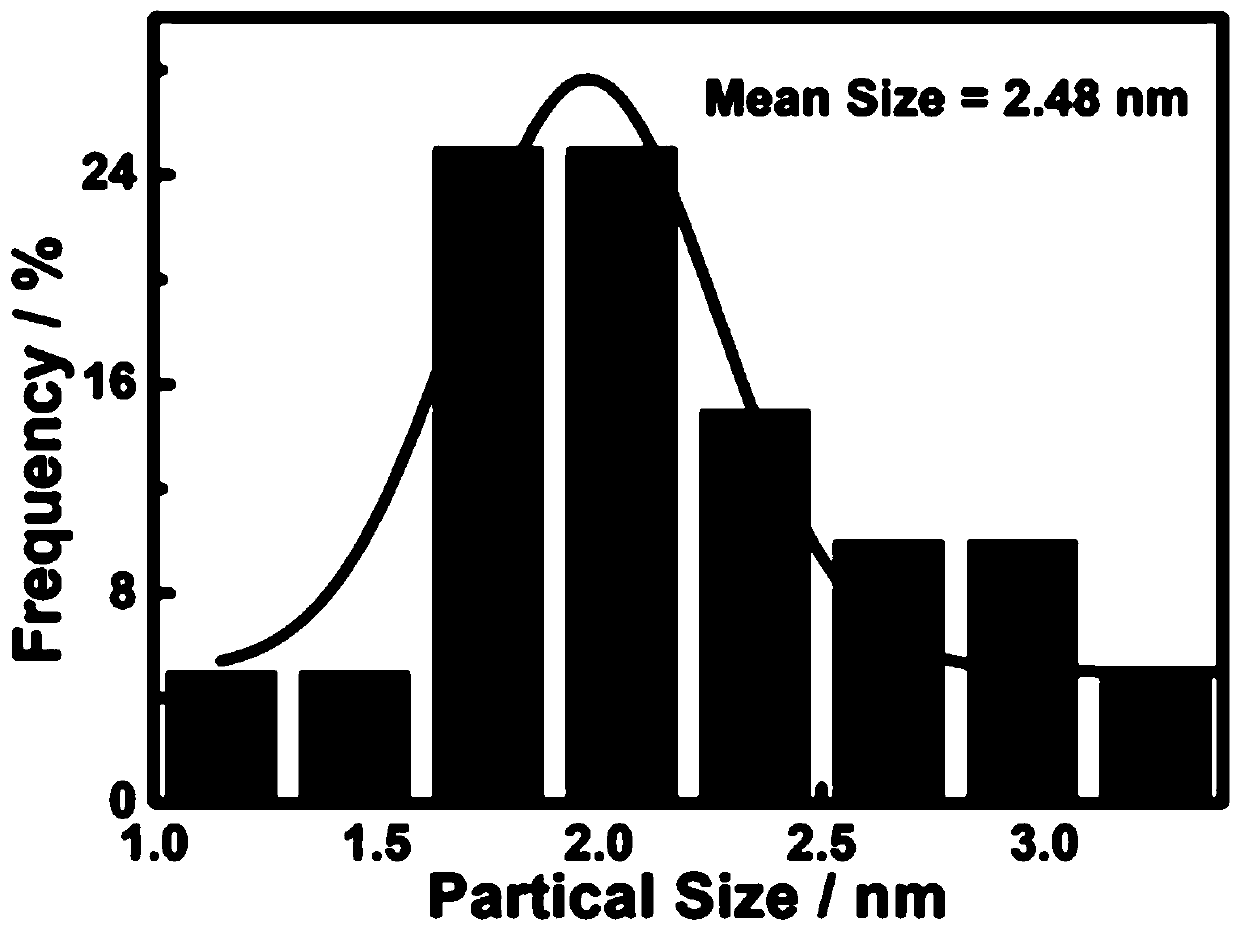

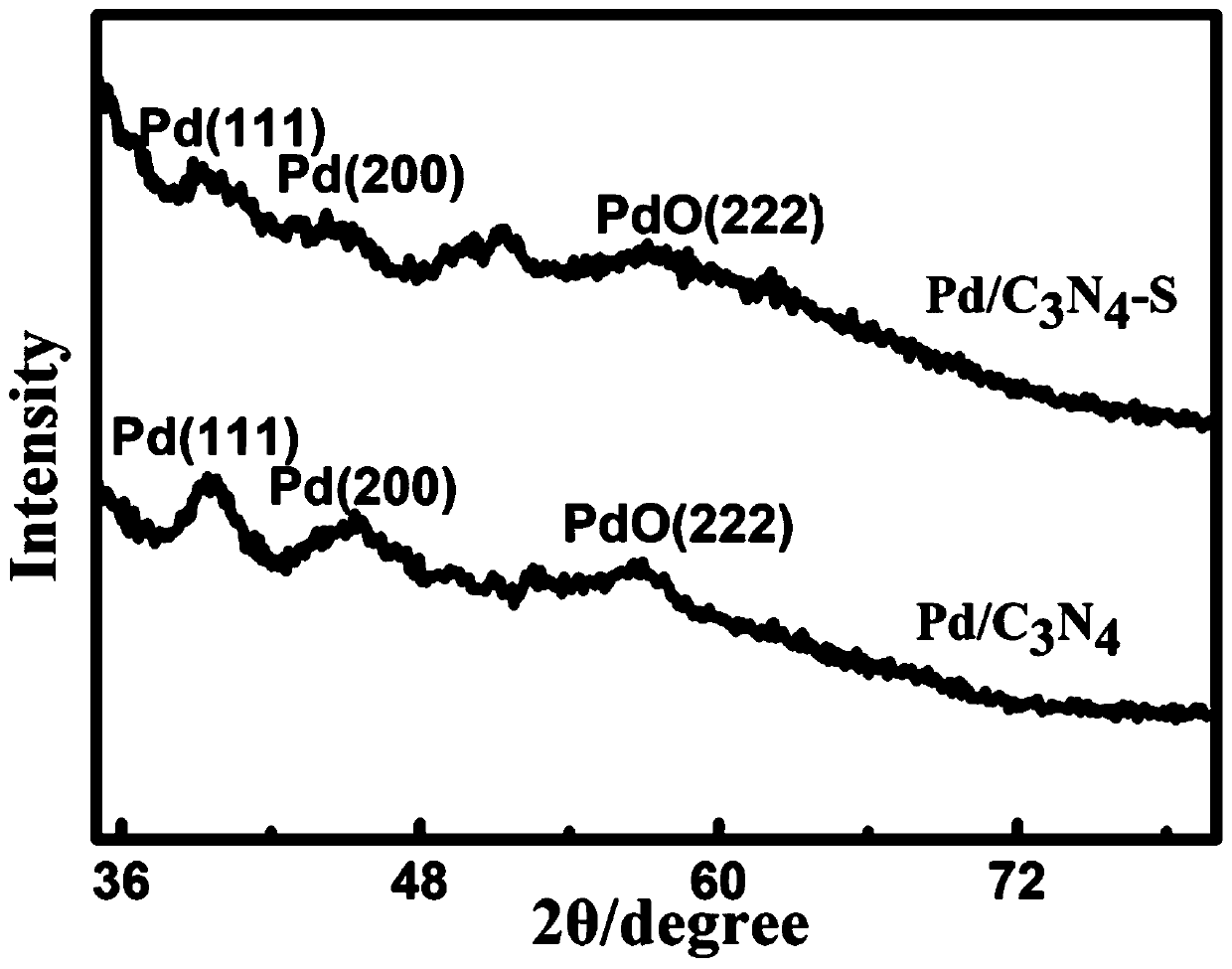

[0070] The Pd nano-catalyst of embodiment 1 ...

Embodiment 2

[0073] Put 2g of thiocyanuric acid in a corundum boat with a cover, put the corundum boat in a muffle furnace, and pyrolyze it at 550°C for 2h under a nitrogen atmosphere to obtain a thin-layer carbon nitride support;

[0074] Add 95mg of thin-layer carbon nitride carrier to 90ml of deionized water, and disperse evenly by ultrasonic to obtain a homogeneous suspension 1;

[0075] 0.85mlH 2 PdCl 4 Solution (5.9mg / ml) was added to suspension 1 to obtain suspension 2, stirred for 2h,

[0076] Adjust the pH of the solution to 11 with a freshly prepared 1mol / L NaOH solution to obtain a homogeneous suspension 3;

[0077] Add 5ml of sodium borohydride solution (1mg / ml) into the above suspension 3, and keep it at room temperature for more than 4h to obtain suspension 4, which is suction filtered, washed with water, and dried to obtain Pd with uniform particle size. nanocatalyst.

[0078] The Pd nano-catalyst of Example 2 was observed by transmission electron microscope, and its par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com